Of my favorite trips to take, right up there with the Knob Creek Machine Gun Shoot, is the trip to Trinidad, Colorado for the NRA Summer Gunsmithing Courses at Trinidad State Junior College. Basically, these courses are a week or two (depending on the specific course) of training on a gunsmithing subject or task. They have a whole variety of classes on different gunsmithing topics from welding and machining to building custom 1911s. For those of you not interested in working on “Fudd Guns” they have classes for you as well, with classes covering the modern spray-on finishes, AR15 courses, etc. In addition, there are classes that are relevant to working on all guns, such as the machining courses. The classes vary somewhat year to year. Information on the NRA Summer Gunsmithing Courses can be found HERE.

This year has been a weird year for a lot of things and school was no different. Regrettably, the usual schedule of classes was greatly reduced due to COVID. In fact, Trinidad State was the only school with summer gunsmithing courses to hold any classes at all to my knowledge. We were, however, required to wear masks by local health regulations to allow these classes to take place. At least I was still able to take the last course I needed for my certificate: Gunsmithing Hand Tools.

The point of this class is to teach the use of files and other hand tools, forging, and other simple metalworking techniques. In this class, you make a few different tools using hand tools and other simple techniques. The real point of this is not so much making the tools, as learning the processes. This is an excellent class for the hobbyist, as it focuses on how to do things without a lot of expensive equipment.

The instructor for this class is Fred Weisenborn. Fred is an excellent instructor, with lots of experience, and lots of patience for people with lots of questions like me. This class is intended for people with little or no experience. But even though I have several years of metal working experience, I still learned a lot and found the class enjoyable and interesting. Typically, I try to get pictures of the work as I’m actually doing it. But most of what we did in this class requires both hands, so I took pictures of the demonstrations instead. Fred was a really good sport about letting me take lots of pictures during his demonstrations.

Day one started with instruction on forging and description of the first project; a buttstock screwdriver. This was to be made of 01 tool steel. In fairly short order we were pre-heating our material in the forge. Then we proceeded into forging the screwdriver blade. For those of you reading this unfamiliar with the process, forging involves heating a piece of steel until it’s glowing and hitting it with a hammer on an anvil to force it into a different shape. You can’t get all the way from a piece of round stock to a screwdriver blade in one shot. It takes several rounds of heating and beating the part to get the desired shape.

After we finished forging and the parts had cooled off, it was time to temper them. Basically, tempering is heating the steel to reduce its hardness. This was done because the steel was too hard to file after forging. Some of you who are familiar with metallurgy may be asking why the parts weren’t put through an annealing cycle at this point. Primarily this was because of time constraints. But this was also to demonstrate how to temper a part without a heat treat oven. Our instructor covered the tempering procedure. Steel turns different colors as it is heated, and those different colors indicate fairly specific temperatures. After the forging process, it was necessary to polish the material so that the colors could be seen as we heated them for tempering. We used abrasive cloth for this, as the material was too hard for it to be cut with a file. After this was completed, we heated the parts in the forge to the proper temperature to temper them, using the colors as a guide as to the material’s temperature. With the screwdriver blades now soft enough to cut with a file, we set to filing our parts. Forging the blades basically “roughed out” the shape. We were to use files to finish out the blades. There are a lot of ins and outs to using a file. So naturally, this course involves a lot of filing.

The second day began with some instruction on metallurgy. This covered definitions for all of the relevant terms. If you are new to the metalworking side of gunsmithing, this portion of the class is extremely useful in understanding exactly what these processes are. This was followed with some instructions on the different types of metals, and their nomenclature systems. We also received instruction on how to properly polish metal. Then we continued working on the screwdriver project.

Later on, our instructor demonstrated the hardening process for the steel we are using. He also demonstrated the importance of getting the right temperature while hardening the part, by overheating a part and breaking it. For the purpose of comparison, a part was also heated to the proper hardening temperature and breaking it as well to show the difference. Part of this discussion was the differences in grain structure and what that means in terms of hardness. Even though I have several years of experience in different forms of metalworking, I found this portion of class to be exceptionally interesting. We finished out the day working on our projects. We were provided with details for another forging project to complete as well, a chisel. While none of us were to that point yet (I started this project the next day), it did allow us to have something to move onto when we finished our screwdrivers without having to wait for further instruction.

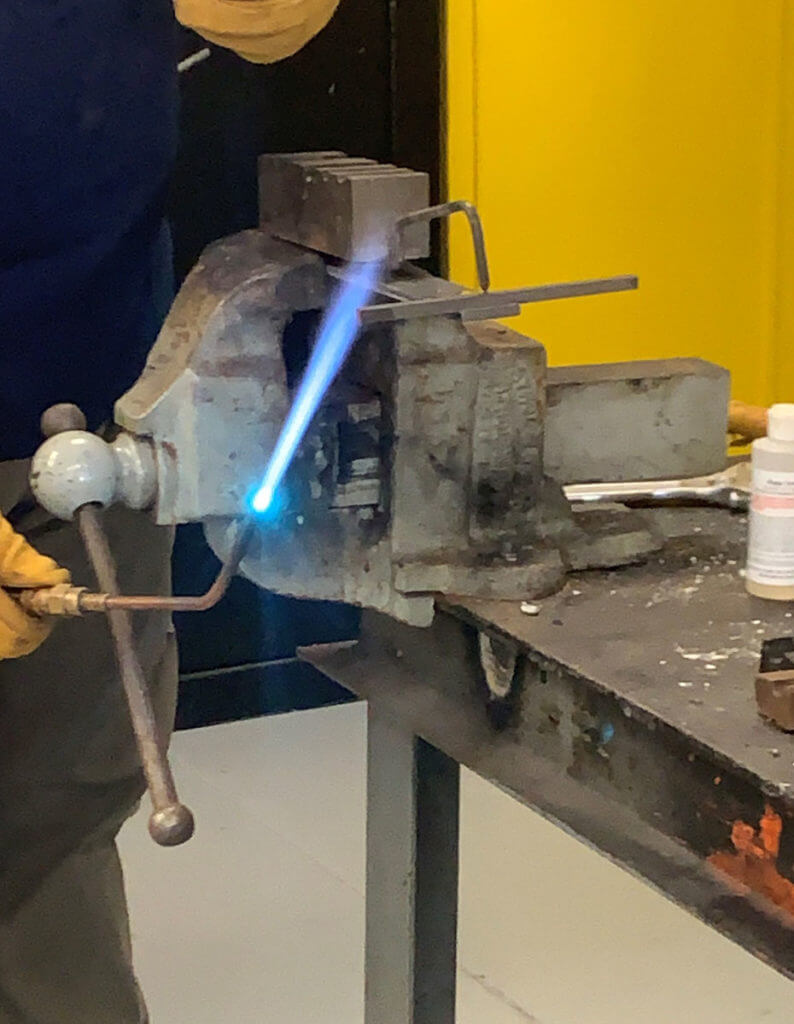

Day three covered a lot of different topics. It began with instruction on soldering and brazing. Part of this was instruction on how to set up and use the oxy-acetylene torch for this purpose. He demonstrated both High Temp and Low Temp soldering. Also the instructor discussed techniques for soldering front sights onto barrels. The instructor also gave a demonstration of oxy-acetylene welding, which is also a handy (though tricky to master) welding technique for equipment challenged folks. We were encouraged to try these techniques and experiment with them.

That afternoon, our instructor demonstrated how to harden tool steel by heating with the torch and then temper it with the same. We used these techniques to harden the tips of the project screwdrivers. A topic I found particularly interesting that we covered was “spark testing”. Spark testing is a low-tech method of identifying different unknown metals. Basically, different materials produce different types of sparks when touched to a grinding wheel. While it can’t sort out exact alloys, it can actually get you in the ballpark. I had heard and read about this technique before, but this was the first time I actually saw it demonstrated. For someone with a home shop, it beats the $10,000+ metal scanners the industrial sector uses for this purpose. We had another pretty quick project that afternoon as well; making a “smoke lamp”. A smoke lamp is a tool used to apply soot to a part to check fitment. Basically, the soot rubs off any contact points so you can very easily see where they are. In my personal experience, I have found that this works better than a lot of other techniques for this. We used our newly learned soldering skills as part of this project.

Something to keep in mind as you read this: the point of these projects isn’t really the acquisition of these tools. The point is to learn the different techniques, and these tool projects help you learn them. Sure, you can go buy a chisel, a screwdriver, or even a smoke lamp. But that won’t teach you how to forge steel, shape it with hand files, harden & temper it, and properly polish its surface to a level suitable of a custom rifle.

On the fourth day, we had instruction on making springs. We made a flat spring as a project. We started from a piece of steel. We filed it to size, forged it to shape, and then heat treated it. The tempering part of this project was interesting, as we tempered these springs in nitre bluing salts. And after it was completed, we tested it by compressing it in a vise. We also were taught about coil springs and braided wire springs. We had opportunity to try some of this as well. I spent some time trying out different methods of both of these. Fred also instructed us on the oxy-acetylene cutting torch, as we hadn’t gotten to it the day prior.

The fifth and final day was intended for finishing up projects. This is pretty standard for classes at Trinidad. You always need that time to wrap things up. I took some time to practice some more forging and some additional spring making while I had Mr. Weisenborn handy to advise me on the finer points. We also did another simple project-casting lead vise jaws. These are very handy to have. If you take the time to really “wrap your head around” this project, it will give you a good baseline of knowledge for casting lead bullets.

I really enjoyed the Gunsmithing Hand Tools class. I would highly recommend it to anyone wanting to learn gunsmithing, even if only as a hobby. The subject matter covered in this class is extremely useful, particularly for folks without a lot of equipment. As I mentioned earlier, this class is intended for folks with little or no experience. So don’t be intimidated if you’re new to the hobby. I have had a very positive experience taking summer classes at Trinidad State, and this one did not disappoint. It was definitely worth the 1200 miles I had to drive to get there. So, if you’d like to learn gunsmithing (or add some additional skills to your repertoire), take a look at the NRA Summer Series Classes at Trinidad State. You won’t be disappointed. Until next time, Happy ‘Smithing!