Editor’s note: This is our second piece on Justin Opinion’s Bob Marvel build. The first part looked at the construction of the gun itself. If you’ve ever had any interest in doing a hands-on build class, I’d highly recommend you read that piece, too.

Check out the work of Bob Marvel: https://bobmarvelcustomguns.com/

Buy one on GunsAmerica: https://www.gunsamerica.com/Search.aspx?T=bob%20marvel

The author chose to finish the gun in dull stainless (blasted) with polished slide flats. If you look closely, you might notice the personalization on the dust cover.

I have a new 1911 that you didn’t see at SHOT. Nor will you see it at the NRA Annual Meeting, or any other trade conference or even at your local gun shop. I know this for certain, because I built the gun myself, and for better or worse it is uniquely mine. If you saw the first part of this story, in which I detailed the experience of attending one of Bob Marvel’s limited classes, then you know the pistol of which I speak. If you didn’t, you should check that out here on GunsAmerica. In this article, I will talk about the gun itself.

I am reluctant to use the word “review” for a gun I built. Never before have I felt so biased in my opinion. But that said, I do possess some perfectionist tendencies and, in many ways, I may also be its harshest critic. But at the end of the day, it is a 1911 in .45 ACP and there is ample basis for comparison.

Let me begin by trying to categorize this pistol. You can buy an entry-level G.I. spec 1911 for about the same price as a good quality polymer framed handgun, or you can spend the equivalent of a very nice used car on one. Whether or not the latter shoots any better than the former is another topic. If you ever become a student of Bob Marvel’s, you’ll understand that last sentence much better. Bob teaches the building of a top quality match grade 1911, and that is where mine falls. Pick your favorite custom house – I’ll put my pistol up against theirs tomorrow.

[one_half]

[/one_half][one_half_last]

The gun from the other side. Note the lack of in-your-face branding and California-legal instructions and warnings.

[/one_half_last]

There’s that bias I was talking about! But what I mean is that I judge the quality of my build by comparing it to recognized top quality 1911s like Les Baer, Wilson Combat, Ed Brown, or yes – even Nighthawk. To help ground my assessment and get some un-biased points of view, I invited several range buddies and competition shooters to try it and give me candid feedback. I chose people that I know have high expectations in a handgun and are familiar with a high quality 1911. Everyone agreed that the gun is tight and shoots great. I got a lot of comments on the trigger pull (tuned to just a bit under 3 lbs.) and the smoothness of the action. One fellow competitor who regularly shoots either an Ed Brown or Les Baer 1911 in IDPA commented about how noticeable the reduction in recoil is. That would be to the credit of the Bob Marvel patented “Everlast” recoil spring and guide rod. It really does make a difference.

[one_half]

[/one_half][one_half_last]

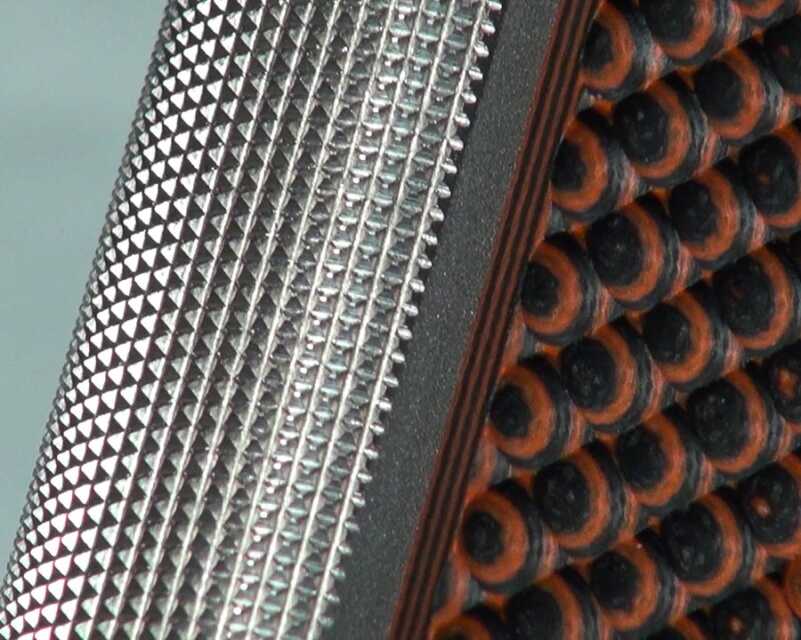

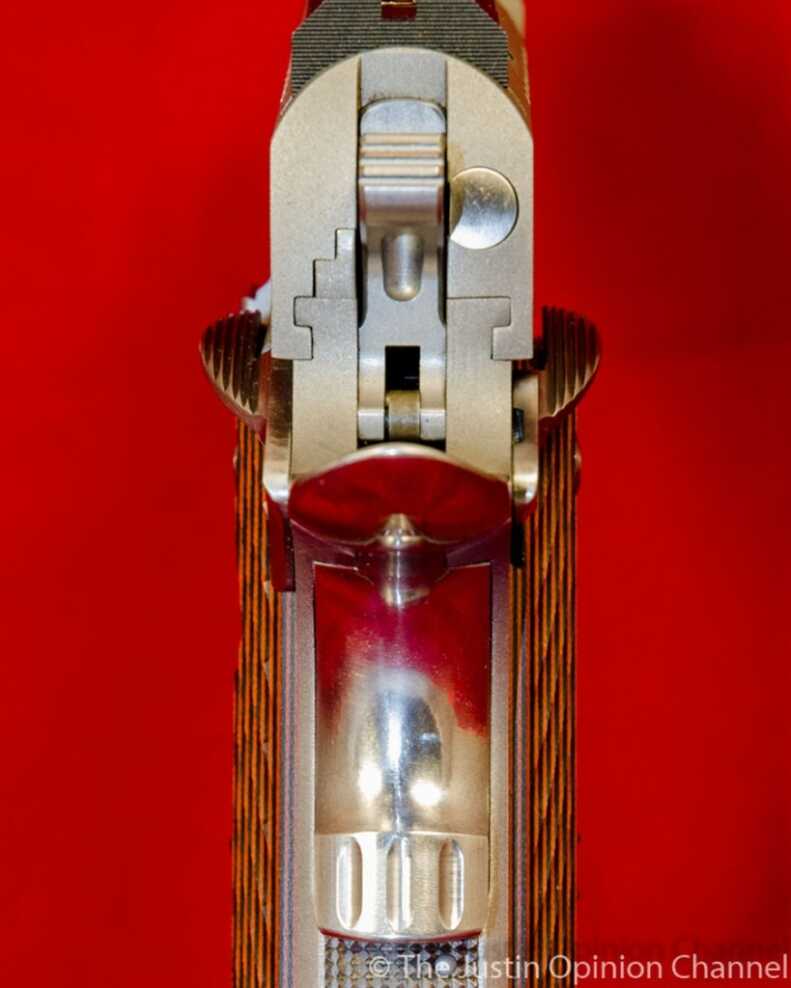

The patented Bob Marvel “Everlast” guide rod and recoil spring system. A full length guide rod and a 22 lb. flat wire spring.

[/one_half_last]

That brings us to the parts and components of this gun. The stainless steel frame and slide were milled to Bob’s exacting specifications by Nighthawk Custom. It’s a Series 70 1911, meaning that there is no firing pin block safety internally. The aforementioned recoil system is Bob’s own design.

[one_half]

You’d better eat your spinach before you try to remove this barrel bushing. And you’ll need a steel wrench!

[/one_half][one_half_last]

[/one_half_last]

Most of the components are Nighthawk Custom, several of which also share the name of Bob Marvel, because he designed them. The barrel and bushing is a Kart match grade pair. The sights are Kensight, the rear is a dovetail fit into a special Bob Marvel slide cut and is adjustable for elevation and windage. The front sight contains a generous length of red fiber optic filament that gathers ambient light and glows brightly.

[one_half]

[/one_half][one_half_last]

[/one_half_last]

The very light skeletonized hammer and the hard sear are from Evolution Gun Works (EGW). To finish it off, the grips are VZ Grips, and the magazine that was provided was a Chip McCormick. The only part that has given me problems is the magazine. I had numerous stoppages and failures due to that magazine, and it has since been benched, with “X”s drawn all over it in Sharpie. Other CMC mags have worked okay, so go figure.

[one_half]

[/one_half][one_half_last]

[/one_half_last]

Shooting the Marvel

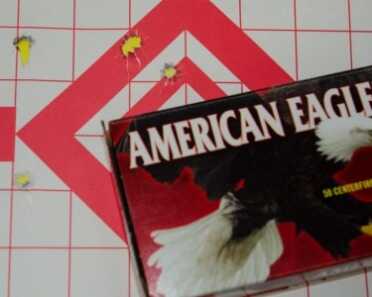

After putting a couple of boxes of “break-in” ammo through the gun, I dialed the sights in for a point of aim – point of impact setup. There really is no break-in necessary, but I wanted to be sure that any settling in of parts fit during recoil would be done before I carefully set the sights. A couple hundred more rounds of just plain joyful shooting, and I was ready to put it to the test in an IDPA match. I built this gun to shoot, not to sit in a safe or be a barbecue gun.

[full_width]

Just as motor sports advance the performance of cars, so too does competition provide a proving ground for firearms. Here, the author shoots an IDPA match with his self-built 1911.

[/full_width]

Competition is where you will learn all the things you need to know about your gun. Are the sights easy to pick up and hold when pushing out fast to the target? How long is the muzzle rise duration? Does the front sight come back on target as expected? Is the safety too tight or too loose? How do the grips feel? The checkering? How is the trigger – can I double-tap by riding the reset or do I slap it? What about mag changes? Does the magazine release operate easily? Do mags drop free? How easy is it to hit the magwell and slam a fresh magazine home? All of these questions and more will be answered in just a couple of stages in an IDPA match. It might take months to really learn those things otherwise – if ever. I learned during the match that this gun is a born match gun. It handles recoil so well that I was putting double-taps in “figure-8” groups. The front sight is right back on target by the time the trigger is reset. This is also where I learned that one of my CMC magazines was causing me serious feeding problems. It took most of the match to isolate the issue, but that aside–the gun ran flawlessly.

[one_half]

[/one_half][one_half_last]

[/one_half_last]

[one_half]

[/one_half][one_half_last]

[/one_half_last]

Next it was time to test the accuracy of this precision pistol. After all, that is probably the most cited reason why anyone would spend the big bucks for a custom 1911. Bob Marvel pistols’ accuracy is legendary. I hoped that since he taught me to build this one, using the parts he hand-picked, it would be extremely accurate. I shot groups with four different ammo brands. All were ball ammo but one. The best group produced in my test was a 3-shot group of Remington UMC that printed a near cloverleaf of 0.710”. The five-shot group of that same ammo was also best at 1.430”. That’s rested at 25 yards with budget friendly factory loads. In the hands of a better marksman with true match grade ammo (and better eyesight), this pistol should be able to print sub-inch groups at 50 yards.

[one_half]

[/one_half][one_half_last]

[/one_half_last]

When I pick this 1911 up and feel the quality of it, and admire the precision fit and top shelf components, I sometimes have to remind myself how it started out. A rough milled frame and slide, and a box of parts. It’s come a long way from there. I’ve considered what changes I might make to it, and I find that there are very few things I’d wish to change. Perhaps cosmetic work, like experimenting with finishes – or just something simple like new grip panels. But mechanically there is nothing that could be done, in my opinion, to improve this gun.

The gunsmiths that have examined it have been impressed. This is one tight 1911. I defy anyone to get any perceivable wiggle in the slide/frame fit. Likewise, I’m buying a beverage of choice for the person that can even detect any play in the barrel lockup when in battery. If it sounds like I’m bragging, I guess I am. Allow me this moment to bask in my achievement – I have so few of them! But the good news is that you too can feel the euphoria of building and shooting a world class custom 1911, if that interests you. Bob Marvel has added more classes to his schedule, but one of these days he will retire, so I’d make it a priority. Visit Deep River Customs to learn more and view schedule options.

Many 1911 enthusiasts dream of one day buying that expensive custom pistol that is not only a joy to shoot and a beauty to behold, but an heirloom that can be passed on. I’m especially proud that I have obtained such a gun – and I built it myself.

[one_half]

[/one_half][one_half_last]

[/one_half_last]

[full_width]

[/full_width][one_half]

[/one_half][one_half_last]

[/one_half_last]

Get more of Justin Opinion on YouTube: www.youtube.com/user/JustinOpinionChannel

Follow Justin Opinion on Twitter: www.twitter.com/Justin_Opinion

Like Justin Opinion on Facebook: www.facebook.com/JustinOpinionChannel

Did you incorporate Schuemann’s process in VIS and horizontal frame surface and did you use hand tools for this. Some detail would be great.

Thanks

I enjoyed your article thus far. I looks like you did a great job.

When will you be post where and how to get hands on the parts and the expected cost?

What do you think the issue is with the couple of malfunctions that you had?

I isolated one magazine that was causing feeding problems. Once it was taken out of the mix, there were no more malfunctions.

Good to hear! Good old 1911 mags, I’ve had to replace a few of them in my life.

Its cool to see how a great shooter comes to be. Wish l had that skillset and what they call “disposable income”. When you run the gun on box after box of full power ammo on a frequent basis do worry about wear or loss of accuracy?

If you properly maintain the gun, and replace wear parts on schedule (springs especially), there is no reason you shouldn’t get 100,000 rounds through it. At that point or before, you’ll need a new barrel – which will need to be fitted. Slide and frame wear will be negligible, so you can continue to replace worn parts for a very long time before there is sufficient wear to the slide/frame to retire it. There are a lot of variables, and I don’t pretend to be the expert – but one can expect very long life from a well built 1911.

You keep talking / bragging about the tight fit. Makes me wonder if it’s to tight when you run it enough to get it hot and the fit tightens up. ?

Ken – The parts of the gun that heat with firing are not really related to the reciprocation of the slide. In theory what you ask might be possible, but in reality it doesn’t occur. You can’t run a 1911 fast enough and long enough to generate that sort of heat. Also, it is a misconception that the slide should be “hard to rack” tight. Even with sub-thousandth tolerances, it glides like its on ball bearings.

Where does one find more information on these pistols. Their absolute works of art and my son and I are very interested in getting more information on these weapons thank you Winslow Jones [email protected]

Might have to search and find a class but they are usually $3995 for a 7 day build class.

If you re-visit the first story, here: https://www.gunsamerica.com/blog/hand-building-a-custom-1911-the-bob-marvel-way/

it has the how and how much information about the class, etc. If you’re just interested in buying one, Bob Marvel still makes guns – but the waiting list would be very long. However, builders like Nighthawk and Deep River Customs (see first article again) have Bob’s endorsement and make fine pistols. Also, check the “buy one on GunsAmerica” link at the top. Good luck!