For those advanced AR builders, or anyone who wants a really cool paperweight, check out RifleOutfit.com. They have raw forgings.

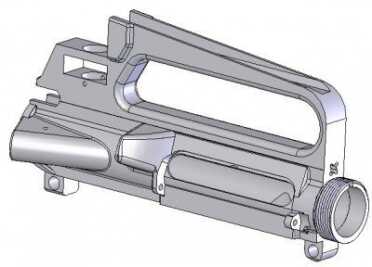

We are running a series of articles on the components that make up an AR-15. Just as the lower is the most important part of the system, the AR upper is easily the second most important building block of the system. Yet the upper is a no-frills part that isn’t sexy. They aren’t pretty. They’re vital, though and easily the one part of the system that counts when building a reliable gun.

THE SERIES

- Part 1: Build an AR-15: The Series Introduction

- Part 2: Build an AR-15: AR Calibers

- Part 3: Build an AR-15: Direct Impingement or Piston Operation

- Part 4: Build an AR-15: Tools and Materials

- Part 5: Build an AR-15: The Lowdown on Lowers

- Part 6: Build an AR-15: Intro to Uppers

- Part 7: Build an AR-15: Barrels

- Part 8: Build an AR-15: Choose The Right Buttstock

- Part 9: Build an AR-15: Choosing the Right Optic

Buy an AR-15 Upper on GunsAmerica: /AR Upper

The history of the upper

AR uppers have been through very little revision since their inception. Along with the lower receiver to which they mate, the upper is the key to the AR-15’s modularity. With two simple pins, the top half of the rifle (which is also the front half) can be removed from the bottom half (which is the back end).

Looking to build a retro rifle? Check out the old-school offerings from NoDak Spud.

Fundamentally, the aluminum shells are the same. The most noticeable visual distinction is the disappearance of the old-school carrying handle. In a world dominated by iron sights, the carrying handle/rear sight was versatile and practical. But slings made the carrying handle obsolete, and there are other options for irons. That real estate on top of the upper could be more versatile as a piccatinny rail. Taking that one step forward, manufacturers made that carry handle removable and allowed for the utilization of 1913 rail mounted optics.

Carry handles aside, optics have to be elevated to allow for a decent cheek weld. With the AR15’s inline recoil system, optics really have to be raised. Otherwise, you have to bend awkwardly to get you eye low enough to see through the scope. Some companies incorporate this elevation into their optic designs. Others rely on risers to create the vertical deviation needed.

Uppers with carrying handles are typically grouped into one (technically mislabeled) mass and refereed to by their military designation–A2. The other uppers–sometimes called A3, M4 or A4–are railed. We’ll break them down in a minute. And just know that all of these labels can get confusing.

Another early change was the standard inclusion of a forward assist. The AR-15 is not the world’s most reliable gun, and it needs a helping hand on occasion. A forward assist pushes the bolt into position. These are damn useful as guns get dirty. Sometimes they get gritty. Sometimes they just get knocked out of battery. The forward assist allows the end user to physically force an out of battery gun into action.

The other interesting addition is the “M4 feed-ramp.” Feed-ramps guide rounds into the chamber and keep them from nosediving inside the upper. Sounds to me like a useful addition. But there are feed-ramps cut into uppers, and feed-ramps cut into barrel extensions… but let’s not get sidetracked. Yet. We’ll talk about that more below.

What does the upper do?

The upper receiver holds the barrel and the bolt carrier group together. It houses the charging handle–the little t-handle you use to manipulate the bolt carrier. It incorporates the forward assist. The last part in the upper receiver is the dust cover–the flap-line door that closes off the chamber and helps keep crap out of the gun. Railed uppers serve as a mounting surface for optics.

Holding the bolt carrier group and barrel aren’t optional. Dust covers and forward assists are. Many of the commercial uppers available will leave off one, or both. This may be a cost cutting measure, or it could be personal preference. If you’re not building a fighting gun, dust covers and forward assists might be extras you can live without. Guns can be kept clean with a bit of care and caution, and a stuck round–when you’re not in a fire-fight–isn’t an emergency.

My take? Rifles are designed to be a closed system. Magazines close off the well, barrel caps prevent debris from entering in the bore, and dust covers prevent dirt and debris from entering the action. I like having the forward assist and the dust cover, just in case. You never know what you might use that rifle for.

Different types of uppers

If there is any potential for screwing up your upper decision, it is this. Not all uppers work with all barrels or gas systems. For the beginner, there shouldn’t be any confusion. 90% or more of the combinations will function fine. Just know that if you plan on building a piston-driven AR, then your upper should accommodate a piston, or the bolt carrier that goes with the piston. Some uppers are propitiatory, which makes life complicated for those of us who like to mix and match. Avoiding trouble is easy enough. If you stay within one manufacturer, for example, for the component parts, you know you’ll be solid. Or simply dry-fit parts.

PWS makes great piston rifles. Check out this video of the PWS piston system at work. Not only is it oddly hypnotic, but the video shows the movement of the BCG and the function of the shell deflector (that hump on the upper we’ve yet to discuss that keeps brass out of your face).

The other thing to consider is how the barrel extension mates with the lower. A2 uppers don’t have feed ramps cut into the lower. Neither does the A3 (a commercial variant without the carry handle). Is that important? Could be. M4 uppers have feed ramps cut into the barrel extension and the lower. But you may notice the confusing switch to the M in front of the 4. Is there an A4 upper? Depends on who you ask. I’m sure the comments will fill up here. I’m not so concerned with the A4/M4 debate. As the commercial market for ARs exploded, the nomenclature has gotten tremendously loose. Just be sure to check for fit. You don’t want the nose of a bullet tucking under a sharp lip of steel. That has a tendency to shut things down.

[full_width]

Checkout this image for a visual guide. See how the steel barrel extensions line up with the cuts (or lack thereof) in the upper? H/T TheHighRoad.org. Lots of great experiential knowledge in the forums.

[/full_width]

[one_half]

[/one_half][one_half_last]

And as they evolve, some of the components get upgraded, like the rear sight on this A2. H/T to AR15outfitters.com for these nice images.

[/one_half_last]

Materials

As with the lowers we covered earlier, there are some basic material differences that you need to understand.

Forged–Aluminum billets hammered into molds that pack the crystalline structure are then milled into a final shape. Very strong. Check out these from Rock River Arms.

[full_width]

[/full_width]

Milled--Milled can be a confusing term. Forged uppers incorporate milling. So do cast uppers. In this middle group, billets of aluminum are cut to spec on a CNC machine. It is a solid upper, and a good option. But the molecular structure mirrors that of the billet it is cut from. Nothing more.

Cast–Cast uppers have the weakest design, as casting molten anything creates a very loose crystalline structure. Of the three, cast uppers are the most brittle. That said, they work fine. How good is good enough? That’s up to you. And your budget.

It comes down to this. Milled and forged uppers have really clean lines. They’re strong, and typically free from casting defects. Cast uppers are plentiful, easy to produce, and therefore easy on the end-user’s wallet. They’re more than capable of doing the job and have been taking-care-of-business since the rifle’s inception.

Are there other materials? Of course! That’s the beauty of the AR platform. I bet someone’s made a functional upper out of wood. Or cheese. Like we covered in the lowers article, steel is an option. Titanium is growing in popularity. Polymer hasn’t proven itself yet, in my opinion. Hybrid polymers are gaining traction, with carbon fiber offering the most promise.

Though it looks intimidating, The Can Cannon is the best fun-gun ever. It is essentially an AR upper mated with a barrel that is designed to fire Coke cans. Read our review of it here.

Uppers are un-serialized

The lower receiver is the registered part of the weapon. This makes upper receivers free game to anyone looking to add some spice to their life. You can order them online dressed how you want, or stripped down to bare metal, and have them shipped to your house.

The fact that they are un-serialized means that you can take your AR-15 and dress it to fit whatever situation you may find yourself in. If you want a short 14.5 pinned barrel and a small Micro-dot sight you can have it. If you want a 20-inch heavy barrel, high-powered scope and a bipod you can have it. Hell if you want a different caliber you can have it, 22lr-50 Beowulf the AR upper is versatile. One lower can support many different uppers, and a lot of the available calibers (which is why some lowers are stamped MULTI instead of 5.56).

So here’s the rub. Once you’ve nailed down the basic aesthetic of the gun, and have the lower in hand, everything else can and should be changed up whenever you feel like it. Most people look at the upper as a whole unit that includes the barrel and all of the accoutrements. This is a great way to stay in the gun-game without drawing too much attention to how many guns you own. For example–if your significant other has a one-in-one-out policy (and I know too many of these sad souls), you still only own one gun. You may have a complete upper that will run .300 AAC, and another that is 5.56, and another that’s makes the whole thing a registered SBR, but it is still only one gun.

The hook on a steel latch like this Badger Ordnance will eat away at an aluminum upper every time you pull back the chagrining handle.

Where they wear

AR-15s are resilient, but not impervious to wear. Uppers tend to wear out with heavy use. When I say heavy, I mean ten’s of thousands of rounds. I have never worn one out–but it is possible. Dust covers will become floppy and need the detents adjusted. A thing you need to watch for (but can’t really fix) is the erosion of the charging handle lock up. Once that handle no longer stays locked, it is time to pat yourself on the back and say “Damn, I shoot a lot,” and pony upper for a new upper receiver.

Closing

Upper receivers are a key part to the AR-15 equation. They’re the reason that the gun is able to be versatile. The upper, and how it mates with the lower, is the foundation to the platform’s modularity.

But it is just a shell. At the end of the day, your upper isn’t a part you should put much thought into but it also isn’t a part that you should skimp out on. But they’re easy to find, easy to install, easy to replace. Diversify and enjoy the gifts of the gun gods.

What are the differences between the “pre ban” lower that makes them incompatible with the “post ban” uppers. Can the differences be resolved? If so, how?

OK I have picked out my barrel(18inch stainless 1/7 wylde) and my upper (m4 forged dustcover and forward assist) but have not bought them yet. now what? their are a bunch of washers spacer’s nuts ect. Do they come with the upper or the barrel or do I buy them separate? I have conference in my ability to put them together onec i have them but every article I read concentrates on the big stuff not the !ittle peaces will their be instructions? I was amazed that my spikes enhanced lower parts kit did not come with directions!!!( I found videos and have a competed lower now thanks)

Very well done. One point to add: if you are building an unserialized firearm but its design fits NFA restrictions, you must comply with NFA registration, taxes and get the Stamp in hand BEFORE the build. This actually negates the “unserialized” advantage as NFA registration requires manufactures (your) markings.