We’re on to part three in our series on how to build an AR-15, and this one is important. We’re going to get technical. If you’re new to this series, I’d like to suggest you read the introduction. If you’re serious about building an AR, it will let you know what you’re getting into.

THE SERIES

- Part 1: Build an AR-15: The Series Introduction

- Part 2: Build an AR-15: AR Calibers

- Part 3: Build an AR-15: Direct Impingement or Piston Operation

- Part 4: Build an AR-15: Tools and Materials

- Part 5: Build an AR-15: The Lowdown on Lowers

- Part 6: Build an AR-15: Intro to Uppers

- Part 7: Build an AR-15: Barrels

- Part 8: Build an AR-15: Choose The Right Buttstock

- Part 9: Build an AR-15: Choosing the Right Optic

All AR-type rifles have plenty of gas; they just deal with it differently.

Eugene Stoner had plenty of gas. So much so that he designed his AR-15 semi-automatic rifle to work entirely on gas flow. The method of operation was called direct impingement. Well, people refer to it as direct impingement, but it’s really a little bit different. We’ll get into that nitty gritty minutia in a bit. For now, just envision those nifty lug wrenches at tire stores that are powered completely by compressed air. It’s a similar concept.

But, as a fellow gun person, you know how we like to tinker. It doesn’t matter if something works or not; we’ve just got to tweak modify and try to improve things. Our collective experimentation has created another type of system for AR-type rifles. That would be piston operation. We’ll explain that in detail in a bit also.

Direct Impingement Operation

I’m going to use the term “direct impingement” here, but only because everyone else does, and it’s commonly known. Technically, Eugene Stoner’s original design is really more like an internal piston that operates inside the bolt carrier. Think of this comparison, and we’ll keep our analogies a little loose for simplicity.

In a pure direct impingement scenario, imagine blasting a jet of compressed air at a lever, like maybe a light switch. With enough air pressure, you’re going to bash the switch hard enough to move it to the opposite position. That hammering like motion with gas it sort of like true direct impingement.

With an internal pistol system, you’re filling the inside of a cylinder with expanding gas. As pressure builds, it’s gonna want to move the piston in the direction of least resistance. Again, with a slightly inexact analogy think of this scenario like a gas engine piston moving as the gas vapor ignites and increases the pressure inside of the cylinder.

Let’s look at exactly how this “direct impingement” or “internal piston” works in an AR-type rifle.

When you fire a cartridge, a veritable boatload of hot and expanding gas pushes the bullet down the barrel. It’s under really big pressure, starting at somewhere around 60,000 pounds per square inch. Of course, that pressure level rapidly declines as the volume between the cartridge base and bullet rapidly increases as the bullet moves down the barrel. The section of the barrel between the chamber and bullet at any given microsecond represents the available volume. And from high school physics, some famous smart guy stated that as volume increases, pressure has to decrease, all else being equal. I think it was Ben Cartwright before he opened that ranch on Bonanza.

Part way down the barrel (the exact position varies depending on the “gas system length” of the rifle in question) there’s a tiny hole that lets gas escape into what’s commonly referred to as the gas block. In original AR-type rifles with the triangular fixed sight, the gas block is contained within the sight assembly, so you really don’t see it as a separate piece. Part of the function of the gas block is to redirect some of the gas back towards the action of the gun. The gas is moving towards the muzzle, then straight up through the hole in the barrel. The gas block redirects it through a gas tube that leads back to the receiver. If you look through holes of the hand guard on an AR-type rifle, you’ll see a (usually) silver tube running between the front sight or gas block and receiver.

On a direct impingement AR-type rifle, the gas tube connects to the gas block and/or front sight and directs gas back to the bolt carrier group in the receiver.

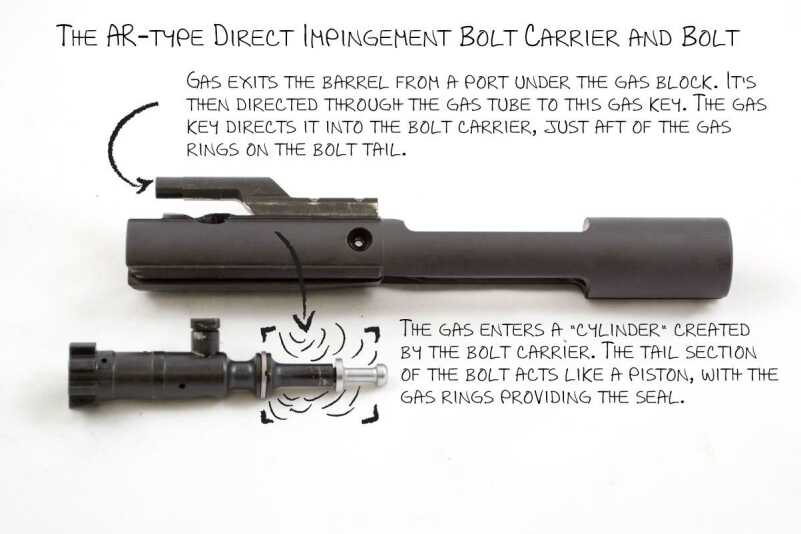

This tube ends at what’s called the gas key on the bolt carrier. The key fits over the gas tube and redirects the gas into the interior of the bolt carrier where it can move the bolt itself. Here, the bolt and carrier act pretty much like a piston (the bolt tail) and a cylinder (the bolt carrier.) The gas enters the bolt carrier and fills a chamber created by the space between the gas rings on the bolt and the internal wall of the bolt carrier where the firing pin body is located.

As gas enters this “cylinder” area, it pushes the bolt in the direction of least resistance, which is actually forward, sort of. In the locked position, the bolt is pressed all the way into the bolt carrier. The expanding gas moves it forward and the carrier backward, so the bolt rotates as the cam pin follows the angled path of the cam pin slot. Once the bolt partially turns and unlocks from the barrel extension, it has nowhere else to go, so the gas pressure inside of our “cylinder” pushes the bolt carrier backward further towards the recoil spring. The bolt carrier movement drags the bolt with it, causing ejection of the round.

At some point, the resistance of the buffer spring overpowers the declining gas pressure and starts to move the whole assembly forward again, picking up a new round in the process. The bolt carrier and bolt slam into the barrel extension and pressure pushes the bolt back inside of the bolt carrier, rotating due to the cam pin slot. The bolt locks into position, and you’re ready to fire another shot.

That’s quite a lot happening in a small fraction of a second. In the context of direct impingement versus piston operation, it all boils down to this. The bolt itself is a piston. The bolt carrier is a cylinder. Rather than a “gas jet bashing motion” the operation is a more gentle expansion in a cylinder that results in movement. Of course, “gentle” is a relative term. Hot and dirty gas flows directly into the bolt assembly causing movement, extraction, hammer re-cocking and chambering of a new round. Don’t let the “hot and dirty gas in the bolt” concern you too much, as it’s a largely self-cleaning system. I don’t mean you don’t have to clean your rifle. I simply mean that gunk doesn’t build up infinitely on the interior of the piston and cylinder surfaces.

Piston Operation

With piston operation, the interface between hot expanding gas and moving parts happens far away from the bolt itself.

When you fire a shot, hot, high-pressure gas moves down the barrel, driving the bullet forward. Piston guns still have a small gas port in the barrel that allows some of the expanding gas to move into a gas block.

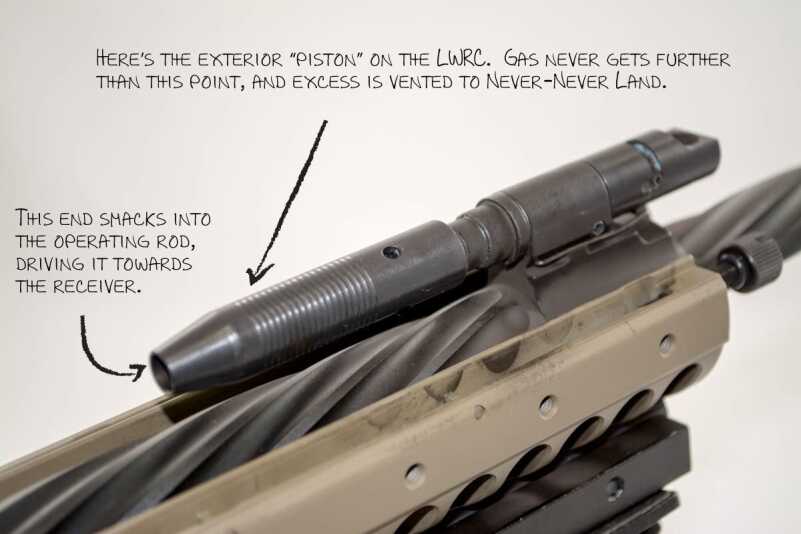

Here’s where the differences between the two systems begin. Rather than directing the gas all the way back to the receiver, the block directs the gas into a cylinder above the barrel. Inside of this cylinder is a piston that moves forward from the gas pressure.

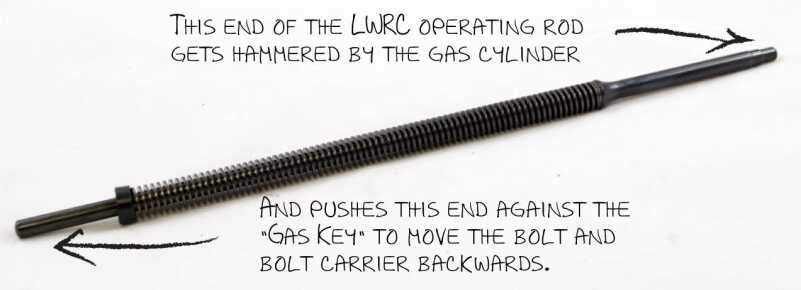

With most designs, the cylinder impacts some type of operating or connecting rod, which carriers the movement back to the bolt carrier group.

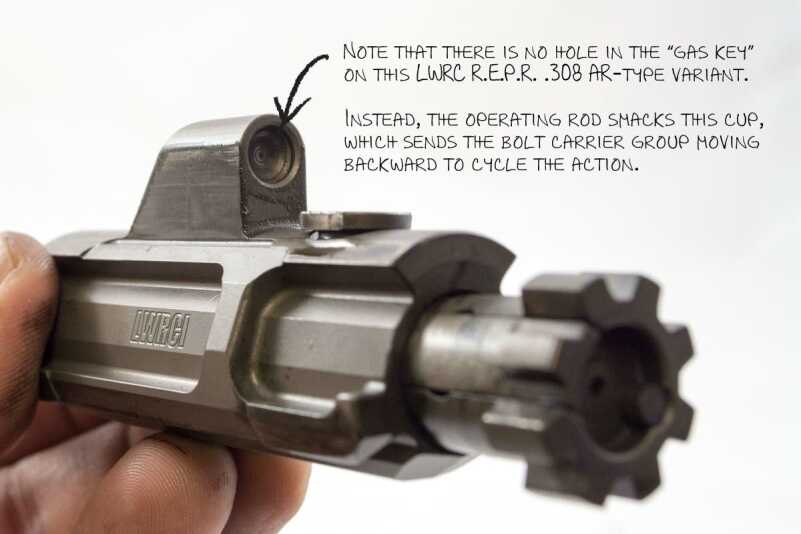

On an AR-type rifle, the connecting rod impacts a modified gas carrier key. On the direct impingement gun, the gas key just directs the flow of gas to the bolt. On a piston gun, the “gas key” equivalent part takes the hit from the connecting rod and pushes the bolt carrier group backward, initiating the same function as with a regular AR-type rifle.

The net-net of the piston system is that the bolt is moved via impact of a metal rod rather than flow of gas into the bolt carrier. The bolt and carrier do not operate as a piston and cylinder – those equivalent parts are located far forward above the barrel.

Pros and Cons

Cleanliness is next to… piston operation?

The direct impingement haters can’t stand the fact that hot, dirty gas blows right into the action of your rifle with each and every shot. That just sounds bad, right?

Of course, there is truth to this. Hot and dirty gas DOES, in fact, go straight into the bolt area. The real question is, how much does that matter? In my view, not much. The system is designed that way and offers plenty of offsetting advantages which we will touch on elsewhere in this section. As mentioned earlier, the carbon build up on the boat tail is largely a self-cleaning scenario. In terms of other cleaning and maintenance, there are fewer moving parts in a direct impingement system, so there are fewer parts to get dirty to the point of malfunction.

This bolt hasn’t been cleaned yet and has hundreds of rounds of .308 through it. Note how clean a piston system keeps the bolt and carrier.

With piston designs, the gas moves a piston located far from the action. After the gas does it’s work, excess is vented to the great outdoors. The net result is that the bolt and carrier area stays pretty darn clean, making your cleaning chores fewer and farther between. On the flip side, you now have parts up front, under the hand guard, that are subject to other types environmental dirt and subsequent jamming.

From a reliability related to cleanliness standpoint, I would consider the two designs a wash. You have different types of “dirt risk” for any type of rifle. The bottom line is that you still need to maintain your gun properly.

Temperature

In a traditional direct impingement AR-type rifle, the gas that enters the bolt and carrier area are HOT. Predictably, those parts, and the surrounding upper receiver, get hot pretty quickly. Unless you’re planning to pull the bolt and carrier out with your bare hands immediately after unloading a few magazines, this isn’t a huge deal. Of course, hotter temperatures can break down lubricants faster, so you will need to pay more attention that and use high quality, temperature-resistant gun oils.

On a piston gun, the action stays surprisingly cool. Of course, the chamber will get hot and bleed heat into surrounding areas, it just takes a lot more shots to get the bolt and carrier area to the same temperature level.

Suppressor use

There are a lot of theoretical arguments about which platform is better for suppressor use, but my view is far more practical. If you use a suppressor, your gun will get filthy, regardless of whether it’s a direct impingement or piston operated model.

Many piston systems offer adjustable gas features which let you decrease the amount of gas fed into the system for suppressor use, or increase the amount of gas for adverse conditions. The extra gas flow makes things work even when dirty, to a degree.

Accuracy

Here’s where potential fighting words start. While I won’t (and can’t) make a definitive claim that traditional direct impingement rifles are more accurate, it’s been my experience that they are. Disclaimer: I have NOT tested enough rifles of both types under strictly controlled conditions to make that claim, it’s just what I have observed over time. I suspect this is for a variety of reasons.

The direct impingement system is a very smooth operation. The flow of gas to the bolt and carrier creates no movement of parts until it enters the cylinder (bolt carrier.) The forward and backward motion of the bolt and carrier is very linear, with no torque or off-center force. To oversimplify, it’s a very smooth action. Piston guns have moving parts along the way, and the force that moves the bolt carrier is “off center.” The connecting rod applies backward motion to the modified gas key on the bolt carrier, potentially creating a non-linear pushing motion. Manufacturers have come up with various solutions to mitigate this, but it’s still at last a theoretical issue. While the bullet is gone by the time all this happens, many folks believe the linear action of the direct impingement system does improve bolt locking and unlocking, which can affect accuracy.

Overall mass might come into play also. The extra piston and operating rod components add weight. And movement of mass during firing cause overall movement. While the bullet is gone by the time things really start to move, this shift mass can force the rifle off target between shorts more than with a direct impingement model.

Standardization

The classic direct impingement AR-type rifles (usually) have interchangeable parts as they follow the design on the original AR-15. Generally speaking, parts are easy to come by from a variety of manufacturers.

Piston designs are generally proprietary. Everyone has a slightly different design, so parts are usually not interchangeable. You’ll almost always have to get replacements and support from the manufacturer of your rifle components.

Which One Should You Build?

Unfortunately I can’t just tell you the answer. Like most things gun-related, much depends on the intended use and your personal preferences. In my opinion, neither is “better” than the other. It’s just like pizza. Double-cheese and Italian sausage isn’t “better” than triple-cheese and pepperoni. It’s just different. Yes, I like lots of cheese on my pizza, but that’s beside the point.

Decide what features you care about for your anticipated type of use. Consider how some of the pros and cons discussed here might impact that way you’re going to use your gun. The good news is that there is no right or wrong decision – it’s really a matter of pizza.

More from this Series:

[display-posts category=”building-an-ar-15″]

Golly, I have over 25,000 rounds through my two BCMs with never a tick, most of those rounds were reloads … 55, 62, and 77grain heads. I pass a patch through the bores every 500 rounds or so. I inspect and wipe down the bcg about as often, but no scraping. What did the sargeants say? “Keep the bitch wet” That’s what I do, I keep the bitches good and wet. It was a good order.

If you are building a pistol… AR vs Piston…

Short barrel AR direct impingement pistols have a reputation for not operating dependably. If you are going DI, then use a 10.5″ Upper. There is a reason BCM doesn’t sell shorter uppers. A BattleComp or similar muzzle device will help increase dwell time and run the gun.

If you are going with a 7.5″ I would recommend an Adams Arms upper or pistol kit.

So, if you want compact light and reliable… go with a piston system.

As for an being practical, pistols are. With a single point sling they are great for clearing a house, and still effective to 100+ yards easy. To put that in perspective, the average police sniper shot is about 75 yards.

The downside to AR pistols is the barrels are short enough for you to get your hands out in front of them. Highly recommend a hand-stop.

looking at an Adams Arms Evo tactical 16″, opinons?

You say tomato, I sat tomato. I have both and the only problem that I have encountered, on a GI, is the bolt failing to cycle after heavy use. Eventually all that carbon buildup has to come out and it does take time to clean properly. Having to physically cycle the bolt after each shot is a huge problem. So my only suggestion is, if you want a GI, keep it as clean as possible. I also have a piston which I have not shot as much but it does stay much cleaner. That in my opinion is enough to own a nice Piston AR. Mine is the Sig 556 and it works like a champ.

AR style weapons with directed gas impingement systems are obviously going to dirty their interiors….and dirty powder equals a weapon that jams ….maybe when you need it most…hey, armchair warriors…VN battle history !!! calcium added to gunpowder…why ???t a better chance of having an operational weapon with the gas piston stroke keeping the gas out of the receiver…something other than direct carbon buildup may jam the weapon…but it will be not be from the barrel directly into the action !!!!….AKs are heavy but reliable….which do you need most ? why carry a weapon ? if you need it, you need it to be very reliable !!! slender barrels are easily bent…AR history ! plastic stocks and buffer tubes will break, break off, collapse when you strike something with them !!! need to carry a buddy to safe place…throw your AR for arm freedom and unlikely to be working when you pick it up !!!! used to teach the use of the WOODEN BUTT of the M1 Garand as method of going to ground and into a firing position in a hurry…same technique works with the M14/M1A, the M1 Carbine, and almost all of the WW II weapons….I have so used a Winchester Model 94 carbine ….and none broke…but the same technique with a Mattie Mattel AR would result in a ruptured stock with the earlier ARs, black finish would rub right off the dearly ARs…bit of heavy use of the ARs and the bolt would have to shoved home….guess why the FORWARD ASSIST DEVICE IS PRESENT ON THE RIGHT SIDE OF THE UPPER RECEIVER ??? most damning bit of the AR is the buffer tube…aluminum breaks so easily…a side stroke with the stock and you need a field replacement !!

While all of your points at one time were valid, they are all ancient history now!

The article was not about which rifle system makes the best club, when you run out of the 8 rounds in the enbloc, it is about different recoil systems.

The issues with the stocks was addressed long, long ago. As was the wrong powder being used, the lack of a cleaning kit and other problems.

The M1 Garand was/is a fine rifle, but was dropped for the M14, because the rifle was prone to some issues that were negative, like heavy 30-06 rounds, compared to the smaller .308 rounds. Then the idea of having a smaller round came up and instead of an AR10, firing .308, we had a 5.56 round.

The discussion goes on and on, if you were military and in Nam, you developed a like and dislike of the rifle they gave you, but every rifle was a compromise by bean counters. The most liked rifle of WWII was the M1 carbine, at least according to many, as they were never left on the battlefield, were the M1 Garand was left behind. Heavy versus light. 🙂

The article is about recoil systems however, not the “best” rifle.

The reason you don’t slam your M16 buttstock on the ground is because it will cause the bolt carrier group to move to the rear. Any grunt knows that.

Well unlike Will, good article!

Too much of the time, when talk of which system is best, it just devolves into hysterics. Too bad, as both systems have their merits and drawbacks, something the article does a decent job discussing.

As for the worry about the original system, the problem in Viet Nam and why direct impingement developed a bad name was incredible simple! The military decided to not issue cleaning equipment with the rifle and the powder for the original ammunition was very dirty, creating a gummy residue. Once these two easy to foresee problems were addressed the original M-16 worked fine. However the mythology surrounding this has continued on.

Some facts: shooting most modern ammunition in an AR will not cause it to jam for thousands of rounds without cleaning.

Shooting dirty ammo causes all rifles problems!

Most problems with ARs are shooter related, not system related.

People that spend the most money on a rifle tend to think they have the best rifle.

I could go on, but the majority of people will understand where I am going.

The current M-4s still have a direct impingement system. Think about it. 🙂

The bottom line, use the type of system that makes you happy, if you are really worried that one system is incredibly inferior to the other, it is highly likely you spend too much time thinking about things that does not matter in real life!!

Go out and enjoy your rifle, do not worry about the system in uses. Instead, worry about where the next bullet is going to land! 🙂

“From a reliability related to cleanliness standpoint, I would consider the two designs a wash. You have different types of “dirt risk” for any type of rifle. The bottom line is that you still need to maintain your gun properly”

Nether the U.S. Military or Real world observations agree with you——–>>>> There is a HUGE reliability difference between DI and Piston guns and anyone telling you different is just to enamored of the original AR system.

Don’t get me started as the entire AR design is so full of flaws that it just needs to recalled.

1. Build a rifle with a precision bore for the carrier to ride in but leave virtually no wiggle room for dirt or sand.

2. Include a seam down both sides of the receiver to let sand in.

3. Use low pressure gas at the carrier so that you have to use WEAK springs to return the carrier to battery.

4. Don’t fix the problem of low pressure gas and weak springs…. Instead add a forward assist.

5. Note that points 1,2 and 3 should have lead to a redesign.

6. Poops into the chamber where all your delicate parts are.

7. Build a load for hot days and short cycles on the cold days….far worse than most rifles.

8. After 30yrs of guns I have no desire to ever own a AR again……

I understand this is an opinion piece..but you need more time with other systems to get the whole picture.

Having owned 3 AR’s (Armalite, Bushmaster, M&P) I can say without a doubt they do not compare with the other guns I’ve owned Aug, G3, SL-8, Sig 556, and if I was ever to return to black guns my first purchase would be a Steyr Aug.

Note my AUG had the fixed handle optics so I sold it….. but the new model…. Gravy

If the AR is so flawed, then why is it the single most used rifle in the United States???

Have you ever looked at other rifles? All I can find are firearms, rifles, pistols and revolvers, even shotguns, with all manner of places for sand to get into! Get serious for a moment and think about what you are saying first. 🙂

Most reliable firearm I ever used was a Mac 10. Only something like 4 moving parts, no separate firing pin, just a tit on the bolt.It too had places for sand, dirt, mud and water to get into it, but it just fired anyway! I think it had more to do with how few parts moved than anything else.

Understand why an AR uses low pressure gas to move the bolt, that is all that is needed!

If you want to slow down the cycle rate, put in a heavier spring, they are available, but be aware of a thing called bolt bounce. Look it up if you do not know what it is. Too heavy a spring will make most if not all auto-loaders have bolt bounce!

If you are having trouble with your ammo on hot days and it won’t cycle properly on a cold day, then get better ammo! Maybe you should look at the powder and charge you are using first!

Ever have a bolt stick on a really hot day from too hot ammo? It is a problem for all firearms if you are not careful or do not understand what happens to your ammo! It can even cause your ammo to out of spec for a competition if you leave it laying in the sun or leave it freezing on the bench!

My G3 does not even use a gas system with tubes, but it always goes bang. However, the ARs are more fun to shoot, at least for me. 🙂 You want to see a dirty chamber, clean any roller block system. Why do you think they have them fluted?

Enjoy your complaining, but remember, much of it is out of ignorance.

Ignorance???

Let”s see hmmmm I built the last AR from parts and head spaced my own barrel. I have owned

A for real Dragunov, 6 AK actions in 5.56 and 7.62×39, a HK G3 and SL8, Calico 9mm and 22 helical fed, beretta Cx4 and 92, Sig 556, Steyr Aug, Glocks, Marlins, Mossbergs, Remmingtons, western fields, Mauser broom handles Lugers, Cz52″s a roller locking pistol and I think I can say without a little pride I know the nuts and bolts of each one… I’m sorry you find my opinion offensive and choose to insult me…. But my Opinion is formed by over 30 years of use and testing…. The AR is accurate and that is it’s only redeeming quality… Though they were bested by the HK SL8…. Do try to understand I could load rounds to match any condition I see fit…. BUT understand the AR system is more problematic to under gassing simply due to the design of the system…. Don’t believe me… Search 300 blackout and AR and all the Holly Grail searching for port sizes and action lengths chats trying to get sub-sonic and transonic rounds to work in the same gun… But I digress…. Of All the guns I bought and sold before they raised the FFL price…. I truly only miss the Aug…. Ok and the Dragunov…

A pal

Yes, ignorance!

Just because you have built some rifles, does not mean you understand what is being said about the AR systems in this article.

As one person mentioned, a bent op rod. Something M1 Garands have a problem with, M-14s and all op rod rifles. Does it make them bad or worse, no, just a different problem area!

All rifles, pistols, firearms have a weak point! When you fix one weak point, another will pop up!

My favorite action is a delayed roller block, but it too has its own issues. 🙂

Saying one type or recoil system is superior to another in an AR is truly ignorant! 🙂

It depends on the failure mode, I see nothing in your post that talks about this. The AR system is subject to contamination.. period. The M1 action is way more robust and not subject to the failure conditions that cause problems in AR systems. You can say what ever you want, but unless you define the environments impact on a particular system then you’re just moving your lips around. The simple fact is that contamination that is just an annoyance in the M1 system will jam up the AR system… I own both and I’m a former Marine who used the M14 before switching over to the M16… and guess what. We considered the AR a toy… and still do. It fun to play around with and fix up with gadgets… and the ammo is cheap. But if my life depended on one gun… M14 period.

This entire article is about ARs and only ARs. More specifically, it’s about two variants of ARs: Piston and traditional direct impingement. Whether other non-AR designs are superior or inferior is completely irrelevant to the topic of deciding what type of AR to build, DI or Piston.

It was the “they break even” comment that riled most people in regards to this article… As people who have owned both will tell you in spades that a DI is in no way the Equal of a piston gun… So they provide real world examples… Including the U.S. Military moving to piston guns…. People don’t mind opinion except when it flies contrary to logic.

I think that depends on what you want. I own both types, and like both, so I have no axe to grind here. Without fail, my DI guns are more accurate than my piston guns, including a $4K Cadillac piston model I have on loan. Is that a scientific and definitive answer? No. We’d need 20K rounds and a series of carefully configured rifles of each type to figure that. On the other hand, I love the maintenance on my piston guns. But then again, for all its reputation as Ol’ Reliable, try putting different .30-06 bullet weight projectiles in that M1 Garand and you’ll see what fun a bent operating rod is in that piston model. Does that detract from the awesomeness of the Garand? Not at all. There are pros and cons to both sides, and it depends what you like and what features you value more than others. Too many folks just pass along information like “hot and dirty gas in the action! Worst thing ever!” without really considering the details of how much of an issue that really is for their intended use of the rifle.

My point in this article is to try to leave some of the theoretical argument behind and figure out how much is really relevant on a day to day basis. As an example, people get all worked up about carbon on parts of the bolt, when most of it, like on the tail, is completely irrelevant to reliable operation.

“Bent operating rod”, The same malady the venerable M-14 suffers when running heavy hunting .308 loads. I sure hope my DI .308 AR doesn’t…oh that’s right …no operating rod..Life is good !!.

Well, if you are going to fire off hundreds of rounds and don’t like cleaning your chamber put a piston kit in it. But with clean burning powder the normal shooter isn’t going to have a problem with carbon fouling the bolt carrier group to the point of jamming.

I owned a AK style rifle and found it less accurate than my AR style rifles but cant lay blame on all Ak style weapons because of the one I owned.

The key word here is owned…past tense. Because I wont own an ill shooting piece.

@Will Drider; No buffer, spring or receiver extension in a GP rifle? Since when?!! So, where exactly does this magical BCG go when it gets pushed rearward?

On a true GP system the bolt only travels within the reciever: AK 47 &74, SIG 550, SIG 556.

A hybrid like your refering to uses parts from two sytems to make a AR something it was not designed to be and you loose several advantages doing so.

Although hybrid (AR-type with GP) systems have buffers, buffer tubes, and springs, their GP systems are much simpler. My POF GP system has two moving parts – a small piston and an operating rod. Extremely simple, solid steel and very robust.

“True GP” weapons that don’t have buffers etc. are not ARs even though they may superficially resemble them. Because ARs with GP systems are ARs, they often have considerable parts compatibility with DI ARs – that is they have fewer proprietary parts in them than DI or GP non-AR guns. (If you want to argue that GP system guns can’t be “true” ARs either, fine. The GP gun with a buffer is one degree of separation from the true AR, while the true GP gun is at least two degrees of separation from a true AR, meaning less parts compatibility with other AR systems, as well as less compatibility with other true GP guns because of proprietary operating mechanisms. Less compatibility can make for more difficulties in SHTF situations.)

@Will Drider; No buffer and tube in a GP rifle? Since when?!! So, where exactly does this magical BCG go when it GATS pushed rearward?

AR DI systems have a buffer tube that contains the buffer and spring PROTRUDING from the rear of the reciever.

A typical GP System contains the return springs within the reciever/piston rod area.

Some hybrid designs for the AR use the standard buffer system to return the bolt to battery but your stuck with the buffer patrusion and the ones that fold won’t fire folded. This type external buffer and GP ststem is common to most AR GP conversion kits.

There is a reason why they make DI to GP kits but no GP to DI kits! Hope this clarifies the information.

WR

” “While the bullet is gone by the time all this happens, many folks believe the linear action of the direct impingement system does improve bolt locking and unlocking, which can affect accuracy.” ”

If the bullet is gone, the accuracy isn’t affected! Every gun I own moves when shot… right, left, up, something has to move. Follow up is relative to movement, and accuracy is relative to where you point the gun. And yes I own several of both types and different makers. “D.I.” guns all react the same, BCG dirty as a pig in a wallow, and will stop with a “dirt lockup” sooner than you think. All the piston guns get dirty at the “piston”, but no “lockup” yet. (I usually run out of ammo (not likely), get too tired (at 110 in the shade, this could happen), or the sun goes down first (as an RSO we stop then))

If pistons were so God awful bad, which the Church of the D.I. Deity dictates, FN FAL’s, Druganov’s, and let’s not forget that horrible A.K, (even an AK can be made “MORE” accurate) etc, would be terrible weapons, history disagrees.

Now I need to go back and run this test again…

” “While the bullet is gone by the time all this happens, many folks believe the linear action of the direct impingement system does improve bolt locking and unlocking, which can affect accuracy.” ”

If the bullet is gone, the accuracy isn’t affected! Every gun I own moves when shot… right, left, up, something has to move. Follow up is relative to movement, and accuracy is relative to where you point the gun. And yes I own several of both types and different makers. “D.I.” guns all react the same, BCG dirty as a pig in a wallow, and will stop with a “dirt lockup” sooner than you think. All the piston guns get dirty at the “piston”, but no “lockup” yet. (I usually run out of ammo (not likely), get too tired (at 110 in the shade, this could happen), or the sun goes down first (as an RSO we stop then))

If pistons were so God awful bad, which the Church of the D.I. Deity dictates, FN FAL’s, Druganov’s, and let’s not forget that horrible A.K, (even an AK can be made “MORE” accurate) etc, would be terrible weapons, history disagrees.

Now I need to go back and run this test again…

You missed the point of what I said. Yes, the bullet is gone, but there is evidence to suggest the non-linear forces of applying a piston fit to a direct impingement design affects lockup. The consistency and repeatability of lockup from shot to shot and over time DOES impact accuracy.

Yes lock up is very critical to accuracy of every firearm!! What happens after the bullet leaves the barrel is always critical to the next round fired!

Too many people do not understand this, but then most people do not understand what makes a firearm accurate in the first place and even less about how to improve accuracy.

Wow, what a great way to confuse two operating systems that were well defined as DIRECT Impingement (DI) and GAS Piston (GP). If you really have to apply the piston term to DI, the upper would be the cylinder and the BCG is the gas driven piston. However, there is no formal recognition from manufactures calling a BCG a “piston”. Your just mudding the water.

You say “Don’t let the “hot and dirty gas in the bolt concern you too much, as it’s a largely self-cleaning system. I don’t mean you don’t have to clean your rifle. I simply mean that gunk doesn’t build up infinitely on the interior of the piston and cylinder surfaces.” Why are they selling thousands of BGC scraping tools? And just where does all the “self cleaned” crud go? What about the rest of the reciever that gets layer upon layer of this baked on crud? How about a history lesson: When these were issued in Nam they came without cleaning kits because they were “self cleaning”. That blatant lie cost too many lives. DI systems put a lot of heat and crud into the reciever and on top of the rounds before feeding them into the chamber which breeds malfunctions. You said ” In terms of other cleaning and maintenance, there are fewer moving parts in a direct impingement system, so there are fewer parts to get dirty to the point of malfunction.” I find your minimizing the difference in cleanliness between the systems inaccurate to the point of irresponsibility.

On a Gas Piston system the gas drives the piston to the rear not forward. This gas action is a impulse where excess pressure is immediately bled off. Gas pressure does not follow the piston to the end of the stroke.

The “some people say” references are weak. Additional weight? Compare the weight of all components: Bolt, piston/rod springs vs Bcg, buffer, tube and gas tube. One ounce difference for a heavy duty system. If that 1oz is a deal breaker for anyone, their focused on the wrong issue.

No mention of the DI systems Achilles Heel. The fragile gas tube that is normally only protected by plastic hand guards in most cases. In heavy use they get bent, melt, split and clog.

You forgot the tail of the dog. DI systems require a buffer, tube and spirng. If your building a pistol version you have 6+ inches that are not needed on a GP system. You can put a arm brace on it and look like a Transformer but do you really want that on your arm in a gunfight? ATF says you can’t shoulder it. The buffer also eliminates the rifle use of a folding stock that still allows you to fire when folded. Folders add great advantage in vehicles and confined spaces. Yes you can get a cheek well on a pistol buffer tube but tou also stand a very good chance of charging handle lip too. You could put that 6+inches into barrel length for more velocity and accuracy.

I am thankful you didn’t use a AK variant for your sample GP system. There are many refined systems out their. The better GP systems have their bolts CONNECTED to the piston rod so there is no SLAMMING effect and corresponding wear.

I’m not a AK fan, won’t own one. Sig and H&K GP systems are my choice. I do keep an old Colt for nostalgia.

I think you were a bit harsh on this article. I learned a lot – from your post too but you’ve identified some issues but only tell half the story. So you know where I am coming from – I was an Infantryman (0311) in the USMC from 89-93. I now work for a Federal Agency whose primary long gun is the M4 platform. I have been shooting M16 and M16 variants for 25 years. I own two civilian AR’s, one 15 and one 10. I own an AK patter rifle as well. I’ve carried M16/M4 rifles in several conflict zones and also was issued an AKM in the Sinai for a long TDY.

“Why are they selling thousands of BGC scraping tools?” – Because the gun industry will always come up with a gimmick to sell to anyone. I learned to clean my rifle in the USMC with the standard cleaning kit issued to me in the buttstock of my rifle. Anything more is a luxury and most likely a gimmick or at the very least, a “nice-to-have”. You really don’t need a specialized “scraper”. I like gimmicks/accessories to, I’ve installed a number of gee-whiz gimmicks, including an AK buffer

“When these were issued in Nam they came without cleaning kits because they were “self cleaning”. That blatant lie cost too many lives.” – That’s being a little disingenuous. If you know anything about the history of the M16 or watch any Military/Discovery channel show on the subject you know the bean counters and brass at the Pentagon changed the original specs of the rifle to get the cost per unit down. They removed the chromed chamber and barrel. The double whammy came when, again for cost reasons they also messed with the propellant in the original .223 cartridge, which turned out to be much dirtier than the original spec. And seriously, what rifle is ever self-cleaning or does not need a cleaning kit? That was an outright BS lie from the Pentagon brass to sell the platform. They should have been prosecuted for that, but I digress. They messed with the original design and once they put it back the way it was intended, plus issuing a cleaning kit, the problems were solved. I have fired tens of thousands of rounds from the DI platform. Most of those from issued weapons, which were arguably harshly treated – sometime thousands of rounds during an exercise. The biggest source of jams I ever encountered was from cheap magazines, GI issue mags being the worst. You have to clean any rifle eventually after heavy use, the M16/AR platform is no exception. Even more so since the tolerances of that platform are much tighter than say an AK platform weapon. It is more finicky, no doubt. But it’s those tolerances that give it better accuracy and longer range. So it’s a give and take. You can’t shoot it forever, but I never encountered a jam or failure to fire in a M16/AR platform because of a weapon choked in carbon – Sandy, or muddy weapon yes, but not from carbon.

“No mention of the DI systems Achilles Heel. The fragile gas tube that is normally only protected by plastic hand guards in most cases. In heavy use they get bent, melt, split and clog”. That’s like saying the Achilles heel of the AK platform are its sights. While they are not particularly awesome and need an actual tool to adjust, they work just fine for the limitations of the rifle. I was infantry -arguably the most demanding duty a rifle can perform is in the infantry. I never, ever saw what you describe happening to an M16 unless it was on a weapon seriously mistreated or grossly misused, i.e. never cleaned or used previously to hoist up a Marine to the roof of a building. I don’t know how many rounds you’d have to fire from an M16/AR rifle to get this to occur, I am guessing a lot; more than I’ve ever fired at one time, and that’s a lot. Maybe an armorer could tell stories but for me the M16 family of weapons using the DI system never let me down. If you take care of your weapon, your weapon will take care of you. That goes for all platforms AK or AR. If you plan to treat your AR weapon like a grunt or think you can treat an AR like an AK, you may have issues down the road, but most people know the difference. I don’t see this as an issue at all for normal non-military/LEO sporting users.

“Yes you can get a cheek well on a pistol buffer tube” – I hope that’s just a misspelling. There’s no such thing as a cheek “well”. “Weld” yes, “well” no.

Good reply! Like way too many armchair “experts”, Will has little concept of the truth about the platform. 🙂

Re: the “scraper.”

They couldn’t be sold if they didn’t meet a need. Wish I had one when I was in, because it would have made cleaning my A1 that much easier. Now I have a GP POF P308, and after hundreds of rounds, the bolt and carrier are still wet with a light coating of lube (that a DI system would have cooked away) that is only very slightly dirty (the lube is black to the touch). The bolt and carrier clean up with the wipe of a cotton cloth. Scrapers aren’t marketed to the owners of GP guns for a reason.

Although both systems will run reliably for many rounds, if you found yourself in a situation in which you don’t know when you might next get a chance to clean your weapon, which would you rather have – the one that poops where it eats, or the one that runs clean?

Well, Will prefers piston rifles, and that’s his prerogative. However, to think that piston rifles are the only good option is also irresponsible. There are somewhere around 8 million military model M-16’s floating around and hundreds of thousands of M4 variants in military service, if not more. That seems to indicate that they actually do work and fire more or less forward on occasion, contrary to theoretical advantages or disadvantages.

As far as the upper being a cylinder and the bolt carrier group being a piston, that’s not at all what I said. The bolt, and more specifically the bolt tail, is the piston and the bolt carrier is the cylinder. Heck, the bolt even has rings just like a car piston. The description of the system being an internal piston design is accurate. Read Stoner’s original patent for more information on that.

BTW, the whole point behind the “self cleaning” aspect is that carbon doesn’t built up on the bolt tail indefinitely. You’ll get a coating, then it will start to burn and flake off, still leaving a layer of course. I clearly said you need to clean your rifle, like any other gun. My point is that people get all worked up about scraping carbon off the bolt tail and some buildup there is largely irrelevant. It’s a non-contact part, and while it looks prettier clean, it doesn’t generally matter a hill of beans if there is carbon on that area or not.

Exactly correct!

Too many people worry about how clean or dirty a firearm is, when the truth is few weapons get dirty enough from powder being burned to cause a problem, most problems are from other foreign matter.

The other totally over looked factor is exactly what was causing the problem with the original M-16s fouling. The problem can be placed directly to some idiot bean counters demanding a cheaper, non-suitable powder be used. These powder left a gummy residue, which coupled with no cleaning kit, lead to jamming failures after thousands of rounds.

When was the last time anyone fired some of that old military ammunition?? Modern powders are clean, do not leave behind the gum and seldom cause any issues!

For those that claim otherwise, then change the powder you are using!