Some causes and remedies for precision problems…

Most guns are more precise than the shooters who own them. And guns leaving the production line these days are even more precise than they used to be. It is not unusual for a production gun to be able to produce groups of one minute of angle (MOA) or less right out of the box. That did not use to be the case, but production techniques have improved drastically in the last few decades.

However, some guns are more precise than others. By precision, we mean the ability to deliver tight groups of multiple rounds. Most people refer to this as accuracy, but what they really mean is precision. There are many factors in any gun that have an effect on precision, and two guns leaving the assembly line, one right after the other, made with the same batch of components and assembled by the same people, can have drastically different precision characteristics.

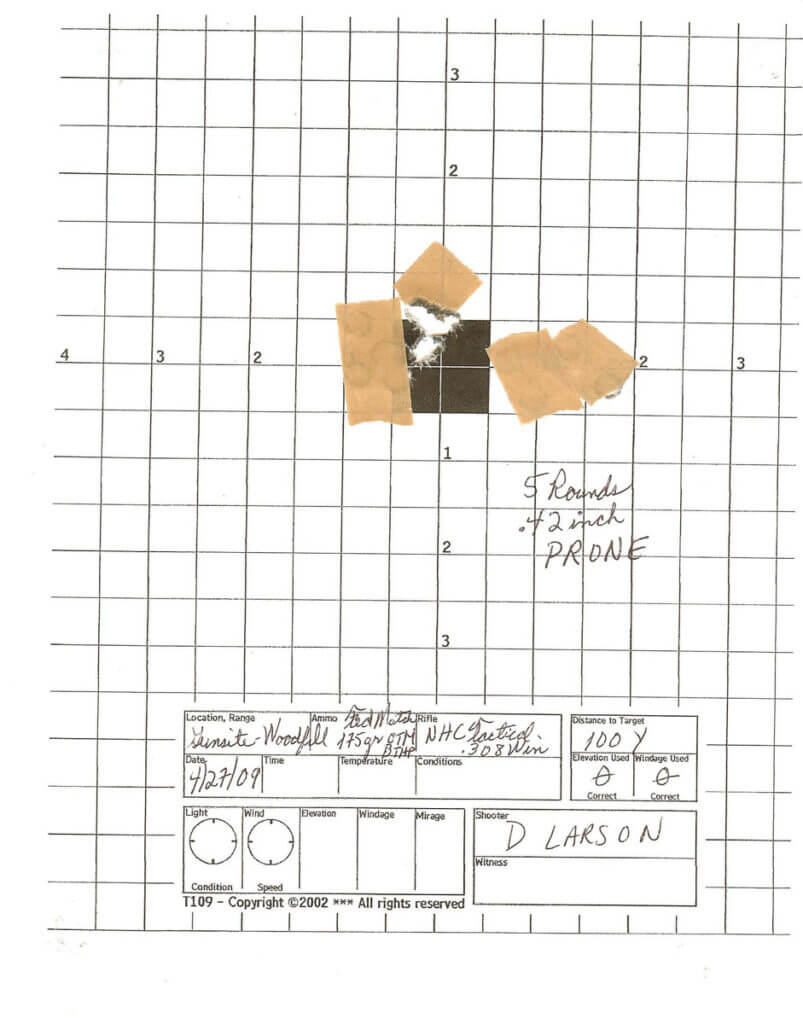

While the first gun may be capable of firing five-shot groups at 100 yards of .5 inch, the very next gun off the line may not be able to do better than 1.5 inch using the same ammunition and shot by the same shooter. It’s because there are hidden characteristics in the metal and the assembly process that cannot be seen or predicted. These characteristics have small but significant effects on the precision of a gun.

But there are some characteristics that affect precision and that can be seen and modified. The trouble is, even though a characteristic affecting precision may be identified, that particular characteristic may not be the one that is adversely affecting precision. Or it could be that the characteristic identified may affect precision when it is combined with another characteristic. So, what to do?

Unfortunately, it’s a case of trial and error in identifying and fixing a precision problem. It doesn’t look like it to the naked eye, but when a gun is fired, the components of the gun (especially the barrel) flex and vibrate. It’s easier to see the vibrations when using high-speed photography that can be played back in slow motion. You can easily find videos illustrating barrel vibrations or harmonics by doing a web search.

When a round is fired, the amount of vibration, especially in the barrel, is remarkable. Even though it may be hard to see the vibration, muzzle movement of say a fraction of an inch can cause a group to open up a considerable amount. If it opens the group up by one inch at 100 yards, that’s ten inches at 1,000 yards.

So, to get the best precision, the bullet should leave the barrel at the same place in the vibration cycle every time. To do that, the gun must be matched with a load that causes the gun to vibrate exactly the same way each time and that causes the bullet to leave the barrel at exactly the same place in the vibration cycle every time.

While the cartridge itself can affect precision, and finding the cartridge that delivers the greatest consistency or precision is a trial and error endeavor, there are other characteristics having to do with the gun, the rest, and the shooter that can also affect precision and that can be influenced by doing certain things. Again, a trial and error procedure should be followed in order to determine and correct the cause of poor precision. Try fixing something, then test the gun. If that fix didn’t repair the problem, try something else and test fire again until the problem is solved.

Often, the cause of poor precision is nothing more than a dirty barrel. While a barrel may appear to be clean, it sometimes is not. When a bullet is fired and passes through the bore, lead, carbon, and other substances can be deposited there. Sometimes those deposits are in layers, so if all the carbon in a layer is removed, the bore may still be dirty because a layer of jacket material might have to be removed before the next layer of carbon fouling can be removed. There may be many layers of fouling, so when the bore appears to be clean, it is a good idea to put another coat of jacket dissolving chemical through the barrel, let it stand for the time prescribed in the chemical’s directions, and then remove it while looking for evidence of another layer. This procedure may have to be repeated several times before it can be confirmed that the barrel is really clean.

After every attempted fix, cleaning or otherwise, another group of cartridges must be fired to test for precision. So, if a screw is found to be loose, then tightened, another group must be fired to see if tightening the screw actually did correct the problem.

It may be that through testing and cleaning, you discover that your gun shoots more precisely if the barrel is slightly fouled instead of being squeaky clean. In that case, a fouling shot or two might have to be taken before the gun is shot for precision.

Recognizing that all barrels vibrate when a round is fired, sometimes it is possible to influence how the barrel vibrates. This can be done by removing all pressure on the barrel or possibly by applying pressure in a certain way to the barrel. Either technique can sometimes work to improve accuracy, but again, it is a trial and error procedure so when something is tried to improve accuracy, the gun will need to be tested to confirm that it worked.

Most often these days, gun manufacturers like to free float barrels. What this means is that all contact between the barrel and the stock or fore-end is eliminated. This permits the barrel to vibrate freely when the gun is fired. A traditional way to check to see if a barrel is free-floated is to see if there is any light visible along the entire barrel profile, or to pull a dollar bill wrapped partially around the barrel through the channel between the barrel and the stock. If the bill slides freely between the two for the length of the barrel, then it is free floated.

Oddly enough though, some barrels actually shoot better if there is some consistent pressure against the barrel in a certain place. To test this, the shooter usually takes one or more business cards and places them between the barrel and the stock or fore-end. If the gun shoots smaller groups with the card or cards in place, the cards or shims can be placed there semi-permanently. A piece of sheet metal or an oil-soaked business card or two usually solves the problem.

Another frequent culprit in precision is the distance between the rifling in the barrel and the bullet before it is fired. Many bullets have a curved profile called an ogive that runs between the bullet point and the full outside diameter of the bullet. This ogive and how deeply seated the bullet is in the cartridge case affect the distance between the unfired bullet and the rifling. That in turn affects how far the bullet must jump before contacting the rifling. Some bullets like to just touch the rifling before the round is fired, and some like to be short of the rifling by a given amount which could be just about anything. Maybe it is 1/10 inch or just a few thousandths. Again, it’s trial and error, and being a hand loader can help figure it out.

And if the shooter hand loads his cartridges, sometimes just changing to a different loading component can make all the difference in precision. Perhaps changing the primer, powder or bullet can affect accuracy. Again, the only way to determine this is to test for it. And if you are a hand loader, the combination of components may be nearly endless.

Another factor that could affect precision are any add-ons or accessories you put on your gun. Those can be especially troublesome if they are attached to anything on the gun that would contact the barrel or the stock. That’s because by doing so, they could affect the vibration of the barrel and alter when the bullet leaves the muzzle, launching it at just the right time that precision is lost.

As mentioned earlier, any loose screws or attachments could also affect precision. It could be something as simple as a fabric mirage cover over a suppressor. If the cover slips around under recoil, it could affect the weight of the cover/suppressor combination which could affect the harmonics or vibration of the barrel. It might be that the loose cover may have to be discarded or a different cover be obtained.

A major factor affecting precision is the ability of the shooter. And a shooter’s ability can vary from day to day. So if you are having precision problems one day, don’t automatically think something is wrong with the gun. This is especially true if your gun was shooting very precise groups but recently changed. You might just be having a difficult day and should try shooting the gun on a different day to determine if it was you or the gun. Or you could ask someone who you know is a good shooter to try shooting the gun.

I once developed a problem shooting AR-15s for precision from the bench. I had been shooting them very well for quite some time, but suddenly my skill deteriorated and I was not able to shoot tight groups regardless of the AR or ammo used. I knew that my shooting technique had suddenly deteriorated and I was doing something wrong. So I consulted Jon Antrim, one of the excellent instructors at Scottsdale Gun Club, and asked him to watch me shoot and then tell me what he thought.

He quietly watched me fire a few rounds, adjusted my right hand on the pistol grip, and I was shooting precisely once again. It was something very simple and obvious to the instructor, but something that I was totally unaware of. It was easy to fix, but without the instructor, I might still be struggling with it.

The point is that there is no substitution for training from a qualified instructor. Gunsite Academy has an excellent reputation and is a good place to check out. Get good instruction and then if your shooting deteriorates, go back for more instruction.

There are a number of items on a gun that can cause poor precision or accuracy. Sometimes, just carefully looking over the gun and tightening any fasteners that have come loose will fix a precision problem. Sometimes you may need to have a gunsmith look at your gun. It may be something as simple as a ding in the muzzle crown which can be fixed quickly and easily by a gunsmith. So consider all the variables and then methodically go through them one by one until you find the culprit.

And don’t think that just because the box of ammunition says that the contents are match grade ammunition that it is going to be the best functioning or most precise ammo for your gun. It could be that there is some inconsistency introduced into the vibration cycle when that particular match ammunition is used. Don’t anticipate the answer. Test the gun and ammunition combination to discover the combination that works best.

And that’s the what and the why of it.

No comments on the B.O.S.S.?

I have a Browning A-Bolt Stainless Stalker in .22-250 that is incredibly good!

there are a few other factors also. I have one rifle that shoots better on low humidity days than high humidity ones. and one rifle that was MOA guaranteed out of the box did so poorly with 20 different loads I was ready to sell the rifle, then a new load came out and I tried it, bingo, sub MOA all day.

Most excellent article Doug. Thanks