When we hear the term “military ball” ammunition most of us equate it with some type of full metal jacketed (FMJ), bullet. Such as, “45 hard ball” being a 230-grain full metal jacketed, round nose for the 1911, or 9mm “ball” being a 115 or 124-grain full metal jacketed, round nose bullet for the military’s 9mms or our own.

The same is true for rifle rounds. Typically, “ball” ammunition has meant a full metal jacket version of everything from 223, 5.56 x 45 up to 50 BMG rounds. However, that simple full copper jacket surrounding a lead core is not even close to what they call ball ammunition today, but we’ll get to that a little later.

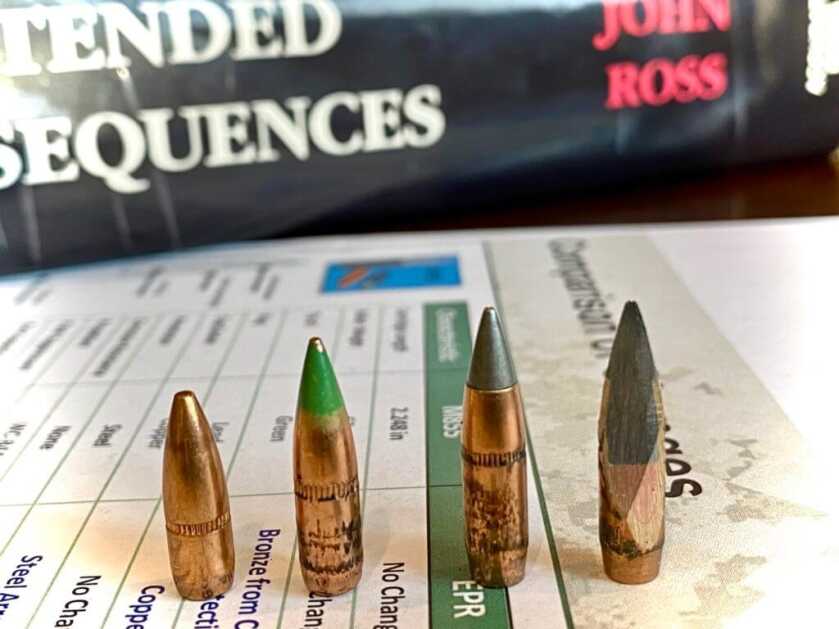

Ball ammunition started over a hundred years ago but for the purposes of this article, we will look at it as it applies to the M16/ M4 era rifles. In September of 1963, a 55-grain Remington designed bullet on the .223 Remington cartridge was officially designated as 5.56 mm Ball M193, the first ball ammunition for the coming M16 that was to be adopted by the US Armed Forces.

The lighter rifle/cartridge combination promised lower recoil and greater hit probability than the 7.62 rifles that were in use previously. The M193 rounds featured a 55-grain FMJ bullet leaving the M16 muzzle at a respectable 3250 fps and a chamber pressure of 52000 psi.

Large quantities of the M193 load are still produced today for foreign military sales, and XM193, the civilian version was widely available until the ammunition shortages of 2020.

The M193 ball ammunition delivered as promised for many years of service. However, the armed forces wanted a round that delivered greater down range penetration performance. So, the hunt was on for a replacement for the M193 ball round.

So, in 1980, after almost 2 decades of M195 service, NATO standardized the 5.56 NATO SS109 with its 62-grain projectile. In the US, the SS109 is designated as M855. The M855 round which can be identified by its green painted tip features a 62-grain bullet comprised of a lead core with a steel penetrator insert all wrapped up within its copper jacket.

Except for the green painted tip, the M855 still looks like conventional ball ammunition. The steel penetrator gave the Army the added punch it was looking for on hard targets at a distance. The heavier 62-grain bullet was however moving at a slower velocity and required a faster twist barrel to stabilize it.

Similarly, to the M195 the M855 served our country well and had been an improvement, but as with all things, it wasn’t perfect. Shortcomings were identified and political influences dictated that there needed to be improvements. More consistent performance was desired on both hard and soft targets, along with addressing environmental concerns.

This set-in motion the development of the M855A1 Enhanced Performance Round (EPR), which would be a whole different breed of ball ammunition. The troops and the environment benefited from the fielding of the M855A1 in 2010.

So right now, you might be wondering where I am going with this history lesson. Well, the event that set this article in motion was running across and purchasing a couple of stripper clips of M855A1 at a recent gun and collector show. With ammo costs what they are I’m glad there was only a couple available, but I figured it was enough for a little research and testing.

Improved performance was an obvious goal, but exactly what did that mean? What was developed is certainly not your typical “ball” projectile. The M855A1 projectile still weighs 62 grains but it is a lead-free projectile. The design was intended to improve performance on hard and soft targets and reduce environmental impacts. I was interested to see what the “new” ball could do.

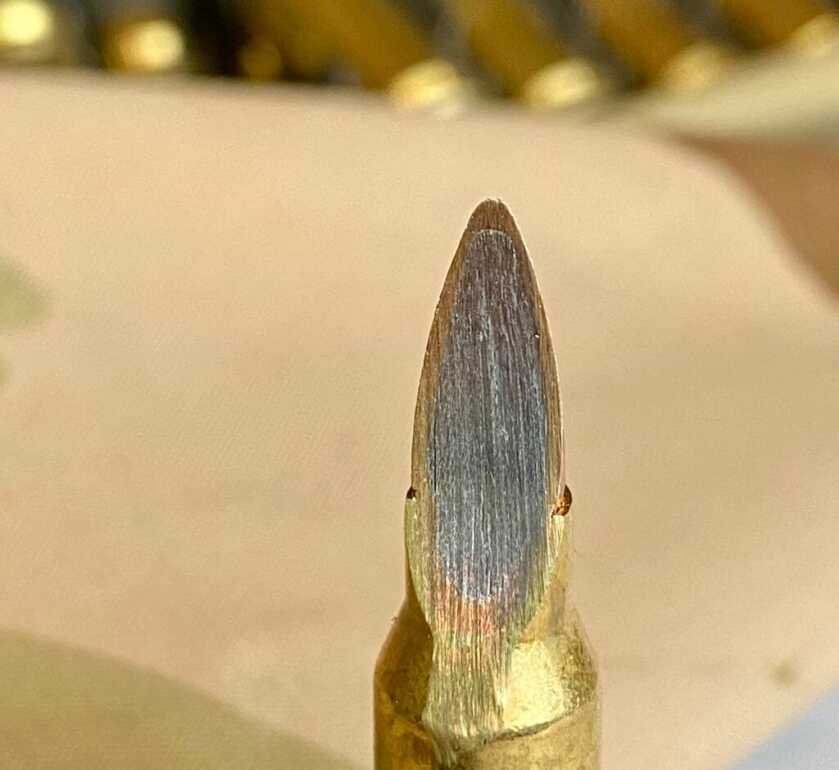

The A1 projectile is made of a larger steel penetrator tip shaped like an arrowhead, a copper slug, and a reverse drawn copper alloy jacket; it definitely doesn’t look or act like any other 5.56 round.

Performance Comparison

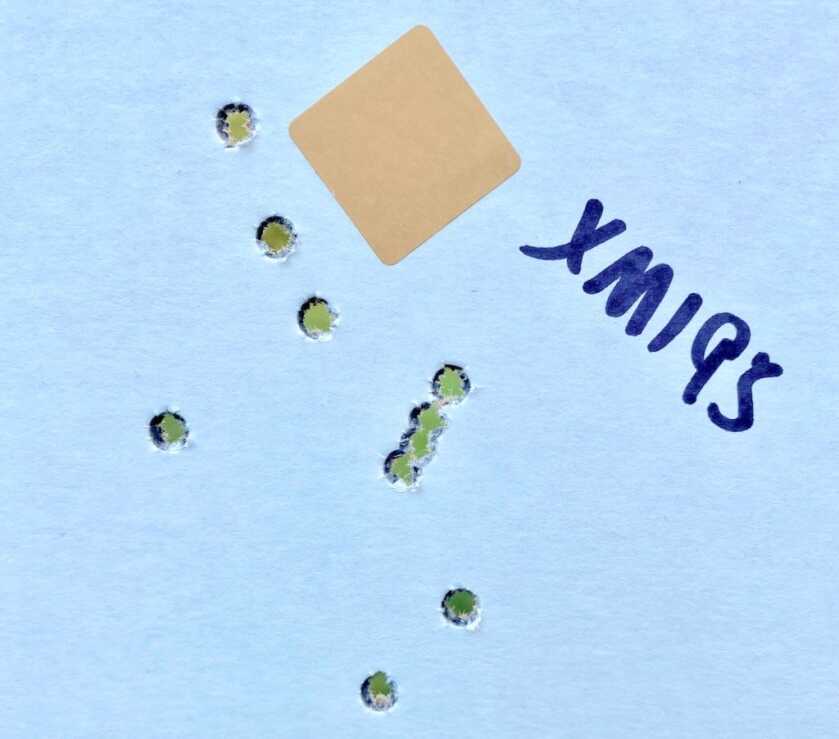

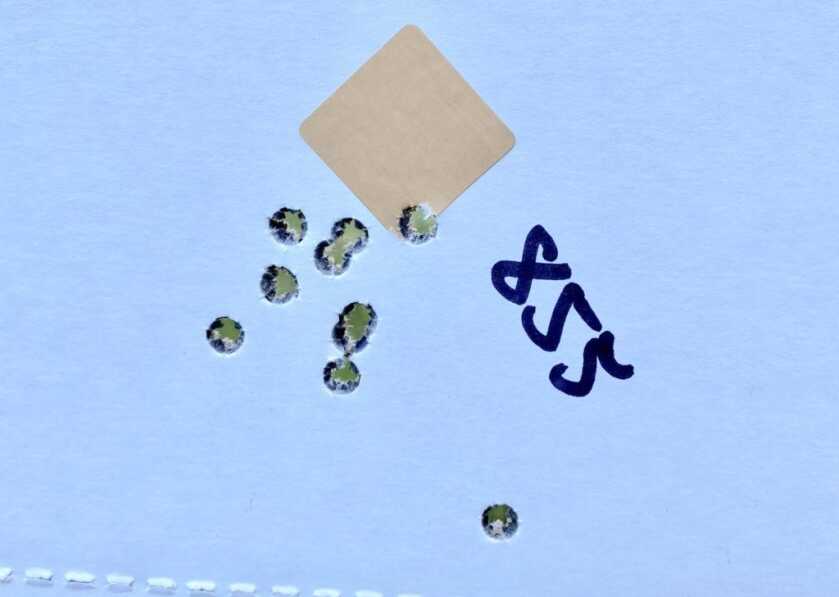

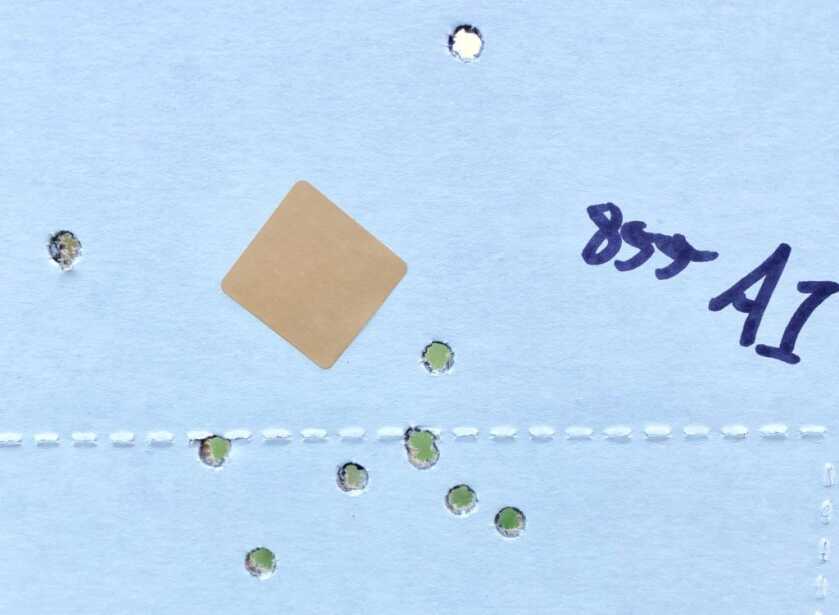

For comparison, all three ammunition types, M193, M855, and M855A1 were shot out of a 14.5” carbine with a 1-8x scope. The M855 clearly demonstrated the best accuracy and excluding the one flyer would have been close to 1 Minute of Angle (MOA), approaching match accuracy. Even with ball ammunition, the troops need to be able to hit the targets. M855A1 didn’t provide very impressive results but was about the norm for most military ball ammunition.

The small sample size I had found made it a one and done for each stage of testing. Obviously, more shooting would have presented a better picture of what averages could provide. However, they did shine while flying across the chronograph.

All three ammunitions were shot for accuracy (10 round group), velocity across a chronograph, and at two types of steel to test hard target performance. The 55-grain bullet of the XM193 posted the fastest average speed, but only 28 fps faster than the heavier M855A1 bullet. That is a very small speed margin, less than 1%, for such an increase in bullet weight, over 10%.

One goal of the M855A1 was to get 20” rifle performance from the shorter 14.5” M4’s more commonly in use today. The A1 round certainly stretches the envelope and pushes the limits in meeting that goal.

Consider for a moment that the A1 projectile has the same 62-grain weight as the M855, but being lead free, the materials are lighter, so the bullet is actually longer in length. The overall length of the cartridge is the same, so the A1 projectile sits deeper in the case than the M855 or M193 meaning it has less case volume for powder.

Less case volume and over 100 fps higher velocity definitely means higher case and chamber pressures. The released Army materials simply reads “increased” for chamber pressure of the M855A1 over the M855, though some sources list pressure at over 60,000psi.

I could feel a noticeable increase in recoil when firing the A1 ammunition, not that a 556 has much, but the difference was clear. One possible drawback to the M855A1 is that the increased velocity and pressures are rumored to decrease bolt and barrel life.

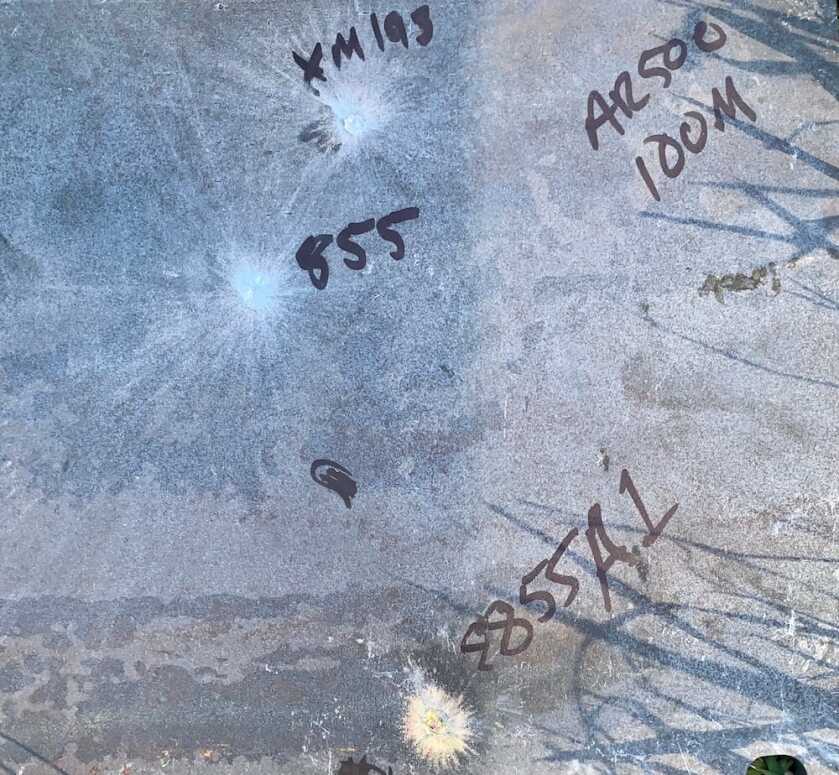

It appears the Army got the velocity increase needed to make the M4 perform more like a 20” barreled M16 with new powder and higher pressures. All three ammunition types penetrated a ½” carbon steel plate at 100 yards, though only one of the two XM193 went all the way through.

None of the ammunition tested is considered Armor Piercing (AP) by the Army. However, it is important that ammunition used by the troops has adequate capability against hard surfaces that enemy combatants may use such as car doors, walls, or other structures used for cover.

Moving out to 200 yards shooting the same ½” carbon steel plate became a whole new story. Neither the M193 nor the M855 penetrated the plate. The M855A1’s fired did, however, punch two holes demonstrating its superiority against more rigid targets at a greater distance. These results weren’t surprising as M855 is only advertised to penetrate 3/8” steel at 160 meters, while A1 is advertised to at 350 meters. Now that’s a performance increase.

I also shot an AR500 plate at 100 yards with all three ammunitions. AR500 is commonly used for rifle targets and is similar in nature to some armor plating. The difference in impact damage on the AR500 plates clearly demonstrated that the M855A1 was packing the most punch of the three ball ammunitions tested, though none came close to penetrating even at 100 yards..

The A1 round was definitely the hands-down winner on both steel targets. That added velocity along with the larger arrowhead-shaped steel penetrator certainly increased the downrange performance on hard targets.

Another important goal was to increase performance against soft targets. I didn’t get to test this but data shows that the A1 round is not yaw dependent and does a much better job against soft targets at all distances than its predecessors. A few more rounds and I would have done some additional testing against some car doors and windshields, these are barriers that typically see ball ammunition fail miserably. However, I think the A1 would have done better than anything I have previously tested.

The M855A1 EPR is an impressive round and was almost everything it was advertised to be, it just lacked a little in the accuracy department, but still wasn’t bad for military ball. It doesn’t look like the “ball” ammunition of the past, however, the M855A1 definitely appears to have provided an increase in bullet performance for our troops; may they be fast and accurate.

The environment is also a big winner, as there are tons less lead being deposited on training ranges throughout the armed forces and less lead exposure during manufacturing.

Buy and Sell on GunsAmerica!

M995 is armor piercing 5.56 mm. 855A1 has better penetration on hard targets, but the military doesn’t classify it as AP.

Generally, AP ammo has a black tip for identification.

Interesting. Yes better for the environment without the lead. Really going to be a pain raking up all those DU rounds I dumped. At least we got hardened valve seats to get the lead out of our gasoline. Bet you do not remember the commercials or PSA with the kids eating paint chips? Can’t eat just one! Lol.

There are so many things wrong with this article it is not even funny. 5.56mm NATO is and always has been loaded to about 62,000 psi, the NATO spec. .223 is a SAMMI cartridge that maxes out at 55,000 psi. They are not the same. It is very, very hard to find M855A1 ammunition because it is Armor Piercing ammo and therefore not allowed to be sold. M855A1 is much more accurate and lethal than M855 as its max effective range is past 600 meters, while the M855 peters out at 400 meters. The Army’s program brief has been in the public domain for quite a while, maybe you should have glanced at it before writing this article.

Virtually nothing Greenwolf70 said here is true.

Note to the public: Search engines are your friend.

I am a Vietnam Vet, and we called it M193 – NOT M195… Proofread… What does it say on that box in the Pics… XM193 !!!

I think you may have mistaken a handwritten “3” for a “5”.

No, he is correct. We called it that because much of our initial issue was still the XM193 clearly marked on every 20 round Lake City box of loose rounds.

The author shows one such box in a photo just above this sentence he provided in the article – “ XM193 averaging over 3000 fps from a 14.5” carbine”

Later issues were marked M193 55 gr