Times change, and technology changes along with it. We hunters have an irrefutable connection with the past; we discuss our favorite cartridges — often with opinions based upon the experiences of our forefathers — and we long for the opportunity to recreate those hunts made famous in the hunting literature we adore so much. However, I feel that if our hunting heroes of yesteryear could’ve had the opportunity to use those tools that we now have available, they’d embrace them immediately. And among all the improvements we’ve seen in the last half century, I rate modern bullet development at the top of the list.

The nearly simultaneous developments of both smokeless powder and jacketed bullets went neatly hand-in-hand; the lead bullets of the blackpowder era had a hard time holding up at the new velocities attainable by the smokeless powder, and a Swiss gentleman by the name of Eduard Rubin had the foresight to place a copper cup around a core of lead. These cup-and-core bullets had no problem holding up to the velocities of smokeless powder; those velocities had broken 2,000 feet per second (fps). Cartridges improved, velocities increased and the cup-and-core bullets were pushed to the point of bullet failure. The impact velocities were so high that the construction of the bullets weren’t strong enough to withstand them, and many instances of bullets exhibiting premature breakup and only superficial wounds on game animals. The most important — and game-changing — occurrence of this bullet failure was when Mr. John Nosler leveled the sights of his .300 Holland & Holland on the shoulder of a large bull moose. John tickled the trigger, put the bullet exactly where he wanted, and created nothing but a superficial wound; more than once. He was so frustrated with the construction of the bullets, that he set out to build a better mousetrap; the Nosler Partition was born and with its inception came the premium bullet industry.

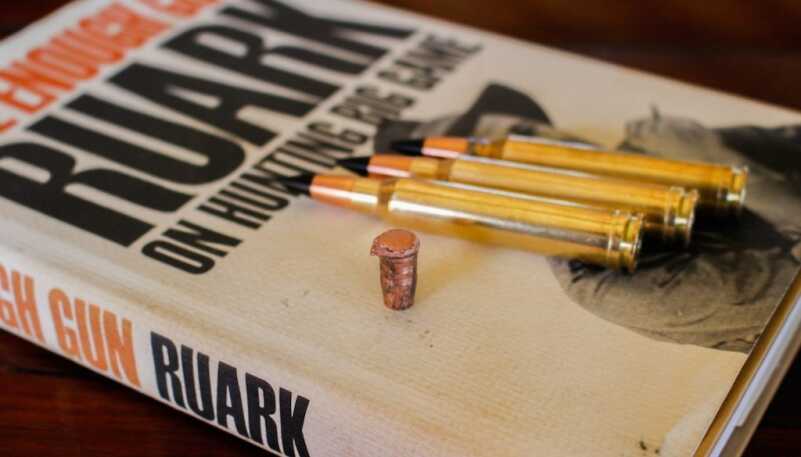

The Swift A-Frame, a bonded core, partitioned bullet. The .416-inch slug was recovered from a Zambian Cape buffalo.

That was almost 70 years ago, and things have come a helluva long way since that moose. Let’s take a look at some of the developments, so we can better tailor our ammunition to the job at hand.

The Considerations

Looking at modern bullets, we must examine two key aspects: construction and confirmation. For hunting purposes, the bullet’s job is to destroy vital tissue. The larger the wound channel — assuming the fact that the bullet can indeed penetrate into vital tissue — the quicker death will ensue. Our job as hunters is to kill quickly and humanely. Allow me to stress this point early on: no bullet, no matter how wonderfully constructed, will solve the problem of a shot in a non-vital area. Simply put, you must destroy vital tissue to kill.

The Peregrine BushMaster, a monometal bullet from South Africa. This was recovered from a Cape buffalo in Mozambique.

Now, the construction of a bullet will certainly aid in reaching those vitals. The first cup-and-core bullets had jackets of varying thicknesses, in an attempt to control the amount of expansion. The more a bullet expands, the faster it will slow down inside an animal. If it breaks up, or expands too rapidly, the penetration will suffer. If it doesn’t expand enough, the wound channel will remain at caliber dimension, resulting in little tissue damage, and a longer time until death. The ‘solid’ or non-expanding bullets were designed for the thick-skinned dangerous game of Africa and India – elephant, buffalo, hippo, etc. – for utterly reliable penetration on an animal with huge bones and tough hide. For our purposes, we will be examining the expanding or soft-point bullets.

The rear section of a 150-grain .30 caliber Cutting Edge Raptor, recovered from a South African kudu bull. The base stays at caliber dimension, while the nose breaks into blades for sever impact trauma.

The confirmation of a bullet plays a role in the performance as well. Generally speaking, the round nose bullets will transmit energy faster but will succumb to the effects of gravity and wind deflection rather quickly. The sleek boat tail bullets work very well in the wind and certainly flatten trajectories quite a bit, but unless strongly constructed, will show a tendency to have the jacket separate from the core. Again, there have been many measures taken to balance out expansion and penetration, as you’ll soon see.

The Traditionals.

Author with a Zambian Cape buffalo, neatly dispatched with a 400-grain Swift A-Frame. Despite thick hide and huge bones, the A-Frame handled the buffalo cleanly.

Those early cup-and-core bullets I told you about? They’re still with us, and still delivering the goods. The jackets have gotten thicker in some instances, to slow expansion, or locked in place with a cannelure. Sometimes the cores have been hardened to provide more resistance. The classic bullets, like the Hornady InterLock and Sierra GameKing, are accurate and effective, providing enough bullet weight is used for the task at hand. While a 150-grain .30 caliber cup-and-core bullet will make an excellent deer bullet, but probably isn’t the best choice for elk or moose. The traditional designs have been given quite a facelift lately — Berger’s line of bullets comes quickly to mind — to maximize efficiency in flight. Having high ballistic coefficient (BC) values, they are good for delivering a bullet on target at long ranges, but there are some who are skeptical about the terminal performance, especially when the shots are close and the impact velocities high. If you like to shoot the traditional cup-and-core bullets, keep the shot distance in mind. I know many hunters who enjoy the trajectory benefits of the 7mm Remington Magnum and .300 Winchester Magnum, yet experience quite a bit of jellified, blood-shot meat and overly large wound channels when the shots are close and a cup-and-core bullet is used. If you think about the terminal performance of the venerable .30-30 Winchester, you’ll find very few complaints about bullet breakup or lack of penetration, primarily because the velocity is mild. When it comes to the traditional bullets, high impact velocity is the enemy of deep penetration.

When choosing a traditional bullet, take a look at a cross sectional diagram of the bullet, taking note of the jacket thickness and Sectional Density value’ you can pick one that will best mate with your chosen cartridge. Some of those Sierra GameKings have good, thick jackets and will perform very well. Some boutique companies like Hawk Bullets will actually offer varying jacket thicknesses.

Bonding Time.

One solution to the problems inherent to cup-and-core bullets is to chemically bond the copper jacket to the lead core. This prevents over-expansion, resulting in deeper penetration. This technique has resulted in some bullets that are extremely reliable, giving excellent terminal performance. Bullets like the Woodleigh Weldcore, Swift Scirocco II, Hornady InterBond, Nosler AccuBond and Federal Trophy Bonded Bear Claw all have their cores bonded to the jacket, and are renowned for their reliability. The Norma Oryx is a bullet that is bonded at the rear section of the jacket, to give a blend of traditional performance up front, and the stability of a bonded core at the base. The North Fork series of softpoints are a blend of pure copper and pure lead, held together with chemical bonding. They offer wonderful terminal ballistics, in addition to accuracy. Bullets in this category have undoubtedly improved the performance of and cartridge; where a .270 was (arguably) considered at the lower end of viable elk and moose cartridges, using a bonded core bullet in Jack’s favorite will definitely get the job done. The added structural integrity make bullets in this class an excellent choice for smashing heavy shoulder bones, or reaching the vital organs from a less-than-perfect angle. If you like to shoot those fast magnums, look to a bonded core bullet for a better performance level than the cup-and-core bullets will provide.

The Partitioned Bullets.

John Nosler’s brilliant idea of using two lead cores, separated by a partition of copper gilding material revolutionized the bullet industry, without a doubt. The Nosler Partition has been used on virtually all game animals – perhaps save elephant – and has been relied upon for hunters around the world since the late 1940s. The front end gives good expansion, while the rear core remains intact to give deep penetration. Some hunters have opined that the Partition is a bit soft for Cape buffalo and other animals with extremely thick hides, but many of them succumb to a Partition each season. It is a great bullet for bear of any color, as well as the larger North American ungulates and all African plains game.

Swift’s other bullet, the excellent A-Frame, is also a partitioned bullet, but with the front core chemically bonded to the thick copper jacket. Strengthening an already wonderful design, Swift has a real winner here, and what I consider one of the top softpoints available on the market today. I’ve used it on species as small as the steenbok, to those as large as the Cape buffalo and eland, and it has performed flawlessly each and every time.

Get The Lead Out.

Modern monometal or homogenous alloy bullets also improve on the traditional bullet design. Randy Brooks of Barnes Bullets fame had the idea to remove the lead core from the classic bullet design, resulting in a projectile comprised entirely of copper gilding metal. If there’s no core and jacket, there’s nothing to separate. He used a scored hollowpoint for expansion, and the Barnes X delivered very deep penetration. Being constructed entirely of copper – a material lighter than lead – the resulting bullet of the same weight will be longer than their cup-and-core counterparts. This will, in some instances, affect bullet stability as the center of gravity will change a bit, but the additional strength greatly improves terminal ballistics. Barnes has several models, including the TSX and polymer-tipped TTSX, but they aren’t the only game in town, The Hornady GMX (Gilding Metal eXpanding) is an excellent bullet, as is the Nosler E-Tip and Federal Trophy Copper. Fouling can pose a problem with monometal bullets, as you’ll have to use an ammonia-based solvent to get it out of your bore, but if you keep things clean you’ll be just fine. Cutting Edge Bullets from Pennsylvania has built their line around ultra-consistent monometal bullets, but with a bit of a twist: the nose section of the bullet is designed to break into small blades, creating immediate impact trauma upon entry, while the base of the bullet remains at caliber dimension (no expansion) to drive deep into the animal. While this may sound a bit unorthodox, I’ve loaded and used Cutting Edge projectiles on all sorts of game, from whitetail deer to the tough African plains game species like wildebeest, zebra and sable, and have had nothing but reliable performance. Peregrine Bullets, from South Africa, offers a series of monometal bullets that use a brass plunger at the nose over an air-filled cavity to initiate expansion. The air pocket isn’t easily compressed, and that drives the sidewall of the bullet out for consistent expansion. Brilliant design, if you ask me, and they’ve worked very well for me in many different calibers.

Berger’s Elite Hunter, a cup-and-core hollowpoint with a sleek ogive, designed for high B.C. values.

I’ve found that with the monometal bullets, you can sometimes get away with using a lighter bullet than you may be used to; they really can’t fail unless the projectile fails to expand. I’ve used a 150-grain Cutting Edge Raptor in my .300 Winchester Magnum, at a muzzle velocity of 3,340 fps, to cleanly take kudu and waterbuck in Africa, with excellent results.

Plastic Tips and Such.

In the quest to achieve higher B.C. values, in addition to initiating expansion upon impact, many of our modern bullets employ a polymer tip. They resist deformation in the rifle’s magazine and aid in flattening out trajectory and increasing performance in windy conditions. You’ll see them on the Nosler Ballistic Tip, The Barnes TTSX, Swift Scirocco II, Hornady SST and others. Hornady however, in some serious Doppler radar testing, actually discovered that at long ranges most of the conventional polymer tips were melting from friction. They revised the formula for the polymer for their ELD-Match and ELD-X bullets, to resist meltdown. While I cannot testify to the fact that any other polymer tips actually do melt, I do know that these new Hornady bullets are fantastic for long range work.

Go Shopping.

Taking all these different designs into consideration, I think you can easily see how the, ahem, ‘boring cartridges’ can easily be given all sorts of new versatility. The .30-’06, which performs so well that some have deemed it a bore, becomes a very interesting cartridge again when you tailor the bullet to the job at hand. A .375 H&H becomes an even better choice when you consider that you can easily take full advantage of these designs. I use a 235-grain Cutting Edge Raptor for plains game and elk/moose, driven at over 2,800 fps, the obvious selection of 300-grain slugs for buffalo and the like, and can even get the 350-grain pair of Woodleigh softpoints and solids if I want more weight for elephant or hippo. Generally speaking, the retained weight of the monometal bullets and the bonded core bullets will be higher than any others, and that’s a good thing, as it goes hand-in-hand with deep penetration. Premium bullets can be expensive, but if you try a couple of the newer designs, you just may give an old rifle a brand new lease on life!

For more information about Barnes Bullets, click here.

For more information about Nosler bullets, click here.

For more information about Hornady ammunition, click here.

To purchase ammo on GunsAmerica, click here.

I started out, primarily Mule Deer hunting with a Model 70 XTR Sporter, push feed in 270 Winchester (Jack O’Connor Fan) using handloaded 150gr Sierra Game King boat tails running at about 3,000 fps, pushed by one of my favorite powders H4831 or IMR4831. Nearly every Mule Deer I shot fell to earth as if they had been struck by lightning or an act of God had occurred. I had then shot a large 3 by 3 Mule Deer hunting with my dad. I spined him high at an angle due to the rock ledge I was standing on above him, the close range and the Mule Deer’s flight. Needless to say after the countless backstrap and steaks wasted, I received a thorough A** chewing from my Dad. This and having struck a Third in the State of Nevada Mule Deer record for that year low in the brisket at 400+ yards, I decided changes were over due.

After repeated handloads and ballistic recordings, primarily seeking accuracy knowing that if shot placement is perfect the rest is history. Having tested the Sierra 130gr Boattail Spitzer, 140gr Boattail Spitzer, the Hornady 130gr b.t.s.p., the 140gr b.t.s.p., the Nosler 150gr Ballistic Tip and the 130gr Ballistic Tip. I found an alternative choice after punching multiple primers out of 12 guage shotshells at 100 yards. I was convinced the Nosler 130gr Ballistic Tip would be a welcome alternate to the 150gr Sierra Game King. The 130gr Nosler Ballistic Tip provided me with better flights at longer ranges and higher velocities for an even flatter trajectory. I was now sending my bullet at 3113fps using IMR4831.

My next Mule Deer hunt with my cousin Jessie was an eye opening experience. I had shot a 3 by 3 Mule Deer in a canyon, on a spring. I estimated the range incorrectly and hit the animal in the leg with a 150gr Sierra Match King. He traveled away from us to the ridge line and was now almost perpendicular at a higher altitude cross canyon. I was now seeing my next shot would be surpassing 425 yards and uphill. My cousin urging me to make a perfect shot asked what are you going to do, stating don’t let him get out of here, well be tracking him forever. I told him I was going to shoot him in the neck. My cousin stating “what, are you crazy.” I reached in my pocket and pulled out several of my handloaded Nosler Ballistic Tip’s loaded them into my Model 70 and repeatedly started counting the yards over and over. Thinking about the drop, I knew even with this load I was going to be low. Remembering my ballistics table the best I could, I knew I would have about 27″ of drop. Laying across a large rock, I raised the cross hairs appropriately as the Mule Deer stood cross canyon with 2 other bucks in tow. Concentrating breathe, exhale, squeeze. I broke the shot hitting the animal almost perfect, center neck. What followed was nothing short of astonishing. I believe in God. This 3 by 3 started a roll off the ridge for 200 plus yards picking up speed as he rolled through one sage brush and then another until he was nearly straight across from us in the canyon.

To surmise, I was proficient with the 150gr Sierra Match King, which would have dropped at that yardage more than 48 inches. I was practiced with the 130gr. Nosler Ballistic Tip prior to the hunt, which dropped about 27.8 inches. My rifle was shooting the 150gr bullet at 100 yards to point of aim, as I remember the 130gr Ballistic Tip was at about 2 inches high at 100 yards. I should have shot the ammunition I had now become more familiar with. Whatever bullet you choose be practiced with that load and know or chart your ballistics table. At this time there were no range finders, few drop compensating reticles, though the Shepard Scope comes to mind. I was using a 3×9 Redfield Widefield and now miss that Colorado company dearly.

I brought and loaded Cutting Edge brass Raptors to Australia, loading them in a 9.3×62 and .376 Steyr. EVERYTHING we shot either dropped where it stood (all rib to rib shots- no spine or shoulder) or took just a few weak, labored steps, before dropping.

Our guide said normally his job starts at the shot…as he has to go find the game. Halfway through the first day, he stated that he’s never seen such lethal, rapid results on game, having seen thousands of head taken before. My friend and I were equally impressed with our safari results “Down Under!”

This is what shooting sports and hunting is all about. One summer I shot 2300 rounds in my .270. the hand loads were 110 gr sierra hp fb. Modest velocity at 2900 fps. That Ruger M77 tang safety was unstoppable. When the hunting season was almost over, I told my soon to be wife…I’m not having a bachelor party. I’m going hunting on the last weekend of the season. As I moved up a brush covered slope I ran into 5 legal bucks. It didn’t have the biggest antlers but he gave me the clearest shot at 200 yards offhand with a full backpack on. Find your rifle’s sweet spot with the rest will put a smile on your face. I rarely shoot over 150 yards and my favorite go-to gun has been a Remington 700 LH muzzlebrake

in .338 win mag ( RECOIL LIKE A 30/06 ) with a 250 gr handload that put three shots into dime with no paper cut showing at 100 yards. It’s a humble journey as we all advance with technology but I’ve got to tell you

It’s Game On!!!!

Have tried many of the so called newer designs in 30-06 and 375 H&H.

Keep going back to more traditional bullets.

Keep loading in 30-06 the 220 gr Nosler Partition at 2400 fps, that semi spitzer design just seems to slip into target and penetrate farther than it should, plus leave a good size hole. That load has provided me decades of reliable performance from woodchucks to moose and plains game – have to recognize that long term performance.

I’ve had great success with Remington Corlokt 150 gr in 7mm Magnum, Remingtons Premier Accutip however shoot much tighter groups ( sub MOA) at 300 yds in my gun but I’ve yet to see how they perform on live game, deer antelope etc.., the Barnes Vor tx all copper with the blue tip are lethal on Elk, but I’ve had a few fliers with that round.

As a long range shooter of PD’s, I appreciate the modern technology of higher BC’s and low drag coefficient’s, but as a big game hunter, I really question the need for the expense of the modern bullets.

Yes, I understand the tech has also helped with expansion and all that, but I’m not so sure it’s all that necessary.

Not for what these components cost anyway.

What I’ve found is that most big game hunters need is more trigger time, and this higher cost is directly related to less shooting time for them.

High end ammo ain’t cheap!

I’ve been using 82gr Cutting Edge Raptors (3-blade design) for a couple of years now on feral hogs coyotes and other assorted critters….can’t say enough about a bullet that has the ability to not only make DRT kills but in most cases make up for errors in bullet placement.