Proper cheek weld is critical for quick target acquisition. If you can’t shoulder your rifle and immediately position your eye to the proper height above your stock and distance from your scope, you’ll spend a few seconds getting a good sight picture. In those few seconds, your prize buck will have moved on to your neighbor’s pasture.

Trust me. It happened last deer season. Not fun.

To make sure I get ’em next year, I decided to make a Kydex cheek riser and install it on my rifle. I could have ordered one, but making it myself allowed me to customize it to my rifle. Plus, it’s way more fun.

Step 1

Step 2

Step 3

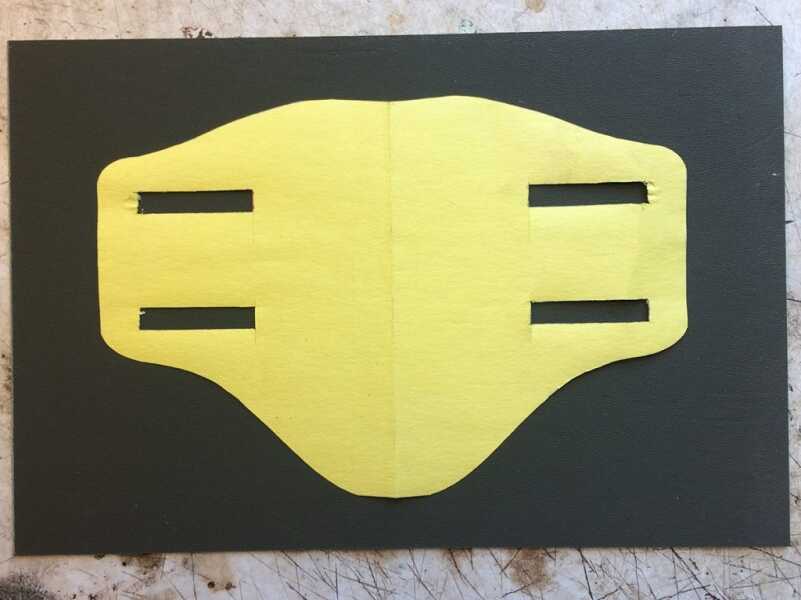

Before cutting the Kydex, it’s important to test the paper pattern on your rifle to make sure it fits.

Step 4

Step 5

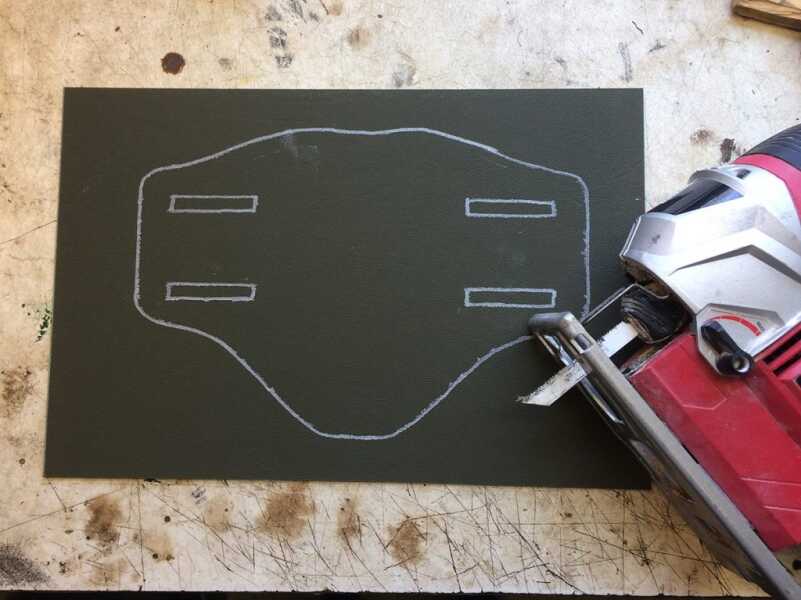

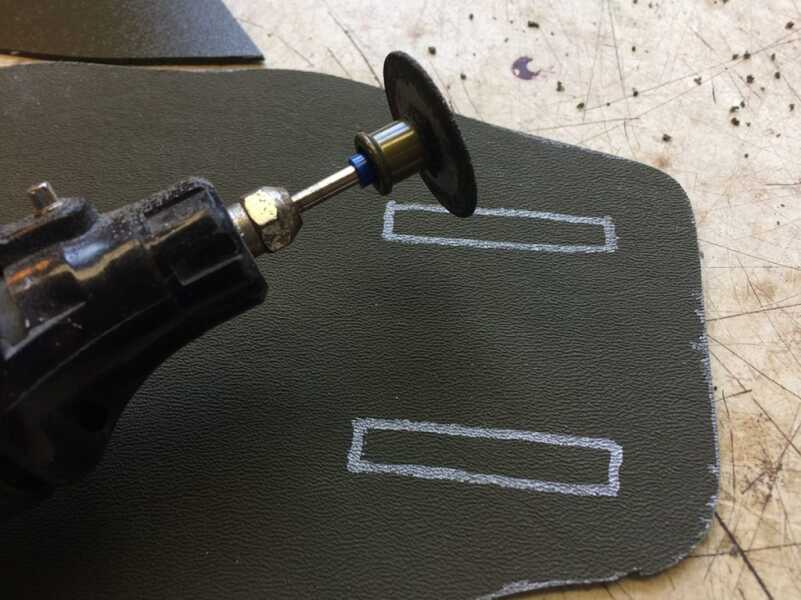

A jig-saw worked well to cut the outer portion of the riser. I also could have used the Dremel, but it would have taken longer.

Step 6

Step 7

Step 8

Step 9

Once everything looked smooth, I popped it into my Redneck Easy Bake Oven at 350 degrees for about 7 minutes.

Step 10

This step took two hands, so I wasn’t able to get a real-time photo. But once the Kydex is pliable, you just bend it around the stock and wait until it re-hardens. Be sure to use gloves. It’s hot.

Step 11

You can use whatever hardware you think is best. I just used these simple threaded bolts. Keep in mind that if the bolts are too long you’ll have to cut them to the right length.

Step 12

Get the riser about where you think it should be and mark where you want the drill holes. I suggest using some kind of vise to keep the stock steady while you drill.

Step 13

I started with a smaller bit and worked my way up. Keep in mind that if you have a synthetic stock it will probably be hollow in the middle.

Step 14

Once you have the holes drilled, all you have to do is install the hardware and tighten it up. I plan to use it for a few range sessions so I know exactly how high I want the riser. Then, I’ll make sure it’s snug and use a little blue Loctite on the bolts.

SEE ALSO: Back to the Basics: Swapping My Tupperware Rifle Stock for a Bell and Carlson

Conclusion

Working with Kydex was much easier than I expected. It’s cheap, easy to cut, and doesn’t take long to soften. I had never made anything with it before this, so if you don’t have any experience with Kydex don’t worry about trying your hand.

The riser itself works great. I’m now able to shoulder my rifle and immediately get a good sight picture. I can also raise or lower the riser to fit my shooting position, and angle it downwards or upwards.

If you struggle sometimes to see through your scope, I’d definitely recommend making a Kydex cheek riser.

If you’re interested in the Savage 11 Hog Hunter (which I highly recommend and reviewed here), you can find one on GunsAmerica for a great price. You can also read about how I swapped out the factory stock for a Bell and Carson.

Many Thanks for the idea!! I work kydex all the time for knife sheaths, but didn’t consider this. I did this on a Gamo Swarm Whisper, and it works great!! Being “old school” I often wonder just why modern scope mounts are so stupid high!?! I always try to “snuggle” the objective lens as close to the barrel as possible….but even with a 40mm objective…. low scope mounts still have the scope too high for a comfortable/repeatable “cheek rest” Nice, Simple answer to what I consider a serious problem!! KUDOS!!!

Wait…….you want us to drill holes in our stocks?not gonna happen on mine.

My stuff has been working just fine all these years.

Just more dam gimmicks.

No thanks sir.

Michael’s Crafts, Hobby Lobby and most other big box chain craft stores have Kydex pieces precut to a size that would work. Painters heat gun from a cheap source and if you run across a copy of the DVD Kitchen Kydex you can even build your own holsters & sheaths.

One thing I’ve done with all my cheek risers is give them a coat of plastic-dip, I sweat a lot and it allows my face to stay in one place, it also works in winter when I have a balaclava on no slipping or sliding

Hollow stock could distort or loosen over time. Double faced tape would enable removal without leaving holes. Velcro patches would be even better, allowing repositioning or removal. Again without holes. Basic ideal is great.

Velcro can be noisy when used.

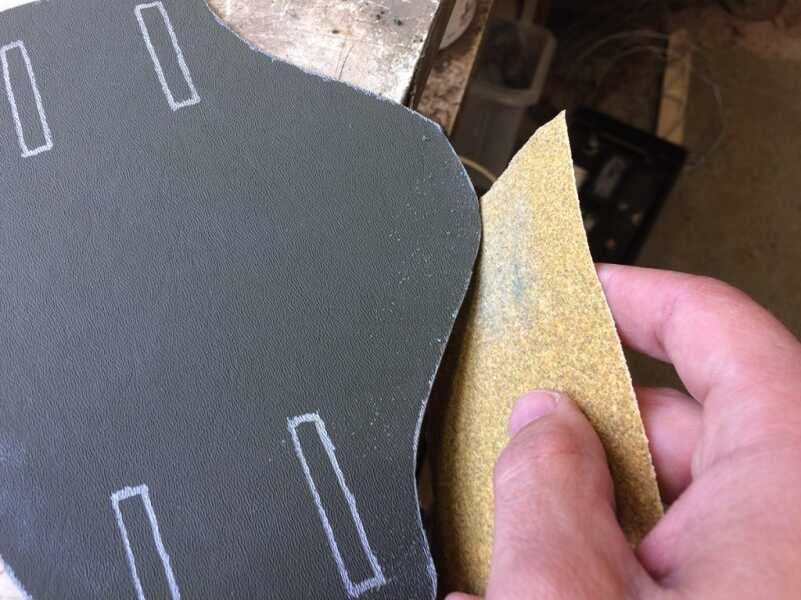

The only recommendation I would offer is that the cutouts should have rounded ends rather than squared ends. Using a drill bit of the right size will accomplish this and make it easier to cut out the rest of the material in the slot.

Over time, the squared ends are subject to cracking due to stress being focused at the corners. The rounded ends spread out that stress and protect the Kydex from cracking.

I use a neoprene ammo sleeve that fits on the batt stock & cut pipe insulation to fit underneath. No drilling holes in stock, softer when you slap it up to your cheek, & can be adjusted for a perfect soght plan.

Great idea! I saw something just like it on a new Savage rifle. I was so disgusted with the crappy stock on my new rifle I put it away but now there’s hope. How about an article on adding length to the butt part of a stock and/or making the butt area larger for real people?

Or you can use a GODA GRIP. Check the website.

Very good idea..Thanks