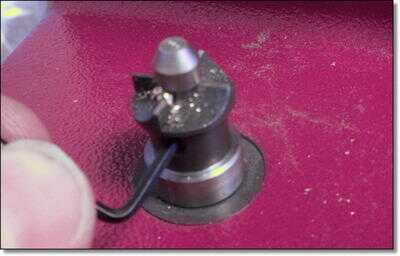

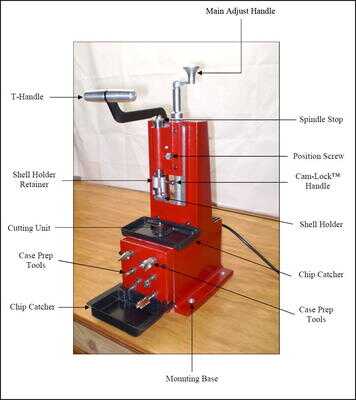

| This is the Hornady Lock-N-Load Case Prep Center. It utilizes a vertical trimming design that solves a lot of problems you encounter with horizontal mounted trimmers. If you are reloading a lot of necked rifle cartridge brass, like this 6.8 SPC, you will need a good trimmer that makes the job easier, not harder. The key to the Lock-N-Load system is this shelholder system, which uses a standard shellholder. The machined disk on top is used with the T-handle to force the shell down onto the cutter, perfectly straight. I mounted the chamfering tools in the middle with the primer cleaning and brush in the top, shown here spinning. The kit comes with pilots and brushes for .22(.223),.25, .270, .308, and .45 caliber necks, as well as the chamfering and primer pocket tools. Standard cleaning brushes are the same thread, and regular Hornady trimmer pilots can be purchased for other neck sizes. The ability to mount up to 6 tools at one time on the front came in handy on the 6.8 because it uses two different primer sizes depending on which brand of ammo you buy. Cleaning primer pockets may sound extreme, but it can help with more consistent ignition and velocity dispersal. |

Hornady Lock-N-Load Case Prep Center

https://www.hornady.com/Lock-N-Load-Power-Case-Prep-Center/

At Midsouth for $366:

https://www.midsouthshooterssupply.com/caseprep/

Case trimming isn’t as complicated as most people make it out to be. The problem is that simple, beginner trimmers are difficult to use, and they give trimming a bad name. If you reload necked rifle cases or plan to reload necked rifle cases, the Hornady Lock-N-Load Case Prep Center, MSRP $531, street price considerably less, makes trimming your cases a lot easier. The Case Prep Center addresses all of the issues that you find when trying to produce ammo in bulk while using a bench mounted, hand crank trimmer. It also includes everything you really need for case prep all in one motorized package, in addition to the actual trimmer. If you aren’t yet a handloader/reloader, check out our introduction to handloading by Scott Meyer. It explains the basics of handloading/reloading, including the dynamics of why you have to trim your cases. If you load only straight wall pistol cases you don’t have to worry about trimming, but if you load, or plan to load, necked rifle cases, trimming is almost always required at some point.

When you fire a cartridge, the base receives most of the pressure, and this “flows” the brass toward the case mouth, making it longer. To be able to fire the case again you need to bring it back to the correct size by trimming some of that flowed brass off of the front of the case. This may sound simple, but if you have ever tried the basic trimming station that comes with most beginner kits, it isn’t as simple as it seems. Beginner trimmers hold the back of the case with an adjustable collet that you adjust to accept the right case size. The mouth of the case is held by a pilot that you set into a pilot holder, which is held against the trimming blades. You match the pilot to the size of the case mouth, which is the same as the bullet diameter that you buy for that cartridge. The pilots in the Hornady hand trimmer are the same as those used by the Lock-N-Load Case Prep Center, but that is where the similarity ends. With a hand trimmer, each case has to be set up and adjusted correctly, with a fairly imprecise dial at the back controlling how much the case is actually trimmed, then you trim, then you have to remove the case and reset the collet. It works, but the work is tedious, and the adjustments tend to un-adjust themselves, even though they are held by a set screw. Even getting the case to stay centered in the collet can even be frustrating, because the whole thing is set up on the horizontal, probably based on the design of a lathe. There are power drill attachments for hand trimmers, but they really only cure one issue, getting the cut started. The whole design of the original hand trimmer is the problem, and the source of headaches from several different design flaws in the basic machine itself, starting with the lathe-type thinking.

The Lock-N-Load Hornady Case Prep Center simplifies the brass trimming process by using more of a drill press approach, with some very well thought out simplifications of how the case is held and cut by the macihne. You lock the case in with a standard shellholder, the same one you will use to hold the cases for resizing and seating in your reloading press. The trimming is vertical, so gravity works with you instead of against you like it does with a horizontal trimmer. A spring tensioned handle separates the adjustment process from loading in each case, so you a case, push down to trim, unload, and load the next, the same way you use a drill press adjustment. Even with the very good manual, it takes a bit to understand how the shellholder assembly holds your case in for you, but once you get it you’ll be off and trimming.

Case prep centers aren’t new. After you trim a case, you have to at the very minimum chamfer the edge, both on the inside and outside, and most people usually then run a brush into the mouth to make sure that burs have been removed. These tasks have been combined in several different machines by Hornady, RCBS and others over the years, but this is the first “all in one” machine I have seen, and this one also trims vertically, which is unique. Hornady also thought to give you extra machining stations for primer pocket cleaning, both small and large, and the trimmings are caught in a tray so you don’t end up with them all over the place. The Lock-N-Load Case Prep Center combines all of these tasks into one machine run by one motor and gear system, with one relatively small footprint on your bench.

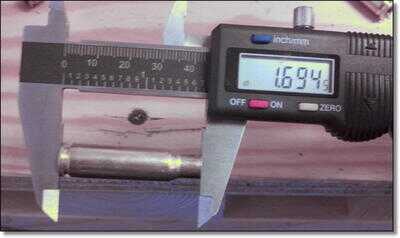

This is one of those tools that I usually don’t even think to write about, but which gets used all the time. These pictures were taken on my phone, reloading some 6.8 SPC ammo. As you can see, the 6.8 SPC cartridge highlights the strengths of the Lock-N-Load Case Prep Center more than your average rifle round, because it uses two primer sizes, both small and large rifle primers. For some strange reason, there seems to be at least two specifications for how you even make the ammo. Hornady brass uses the small rifle primer, the same as the .223/5.56, but Silver State brass comes in both small and large primer sizes, and Remington brass (the cartridge is known as the 6.8 Remington SPC and based on the .30 Remington cartridge), uses large rifle primers. I looked on the SAAMI website, which is the governing body for ammunition, and there is no 6.8 drawing available in the PDF of cartridge drawings, so apparently this cartridge is truly up in the air. The SAAMI specs don’t even seem to include primer options. But since Hornady didn’t skimp on the gear stations, you can put both the small and large primer pocket cleaners into the machine at the same time, so you can sort them as you trim. The Lock-N-Load Case Prep Center also does come with the right pilot for the 6.8, which is the .270/7mm one. so after a quick and easy adjustment, I was able to start trimming and cleaning my 6.8 brass in bulk.

The only downside for some is going to be the price. This is not an inexpensive tool, but it is a lifetime purchase kind of thing that won’t regret if you are a committed reloader. This is a big, heavy, monster of a machine with what is probably a half horsepower motor that should last a lifetime. The case is solid cast iron, and all of the working parts are stainless steel and aluminum. I’m sure Hornady could have made this machine cheaper, but that is what it would have turned out, “cheaper.” Depending on what you consider your time and headaches to be worth, the Case Prep Center should pay for itself relatively quickly, especially in headaches. Once you get to know the workings, you can run brass through the machine almost as quickly as a deprimer, so it is a definite candidate for busy work during Dancing With the Stars or Idol. Mounted on your living room coffee table it’ll not only look good, but it will be an instant conversation starter when you have guests over. This is obviously not a high production item for Hornady, but you can catch a sale on them now and again. One of our advertisers, Midsouth Shooter Supply, is currently running them at $366, which is competitive even with some of the lowball Black Friday sales that came and went. The Hornady Lock-N-Load Case Prep Center is a great gift, and one that will be around for many Christmases to come.

They need to redesign the chip catcher tray,the “ears” on the plastic tray are hard to get behind the screws to lock it and the ears break off (cheap plastic) so small it’s hard to glue them back on.

bad deal hornady case trimmer,case slipped on lock down sent back hornada had for two and half weeks, got it back did same problem after 50 cases, called hornady advised them the adjustment pin has problem, they sent 2 new pins, after only 70 rounds it happened again . they are to send me a new one but the problem still exists. they have had this trimmer longer than I have,and still waiting for the new one after 3 weeks ,donot want this will get rcbs.

I found the Hornady power case prep center at midway for $312. But after all of the negative reviews I’ll keep using my hand tools, much better precision at a fraction of the cost

I also purchased a lock and load case trimmer back in 09-01-2012. Did not start using it until around 04-2014 doing just few 100 .223 to get to know the operation. Started by trimming around rounds in late October of 2013 and the machine started to slow down and cutter started to jump up and out of gears and not turn. I called Hornaday and explained the problem the tech sent a return label and off for repairers it went.

I received the unit back on 11-13-2013. Hornaday had to rebuild the complete unit replacing all the gears,cam lock trimmer cutter, power trimmer cutter spindle and power motor. In early March I started trimming .308 casing, I did not complete 400 casings and again the unit started doing the same thing and stopped.

when the unit comes back from Hornaday. And is repaired, if it fails again. I WILL wash my hands for this unit .

JUST A LITTLE WORD OF ADVICE THINK TWICE BEFORE YOU PURCHASE THIS UNIT. IF I HAD IT TO DO OVER I WOULD HAVE REQUSTED A FULL REFUND AFTER FAILED THE FIRST TIME. NOW NO ONE WANTS TO TAKE RESPONESABLITY FOR A REFUND NOW

I have been trimming .38 SPL, .357 Mag., and other straight wall cases for many years.

I trim them to help get a consistent crimp.

In my experience, case length varies enough to make my crimps erratic, even for straight wall cases like the .38 SPL.

So, my big question is: How well does the Hornady Lock-N-Load Case Prep Center handle trimming short cases like the .38 Super, and .38 SPL?

I bought one on the 22nd of Feb. Received it 25 of Feb. Set it up and started using it that night to start cutting down some .223 LC brass that my hands have been hating doing by hand. I did a 100 the first night, about 200 the second night. Another 200 the following day and on the fourth day the machine stopped, the motored began to humm and nothing turned. Naturally I began to troublesoot. Looking for debris anywhere it could have lodged itself and nothing. Looked at the fuse, good to go. Turned motor by hand moved with some resistance but moved. put everything back together and switched it on. Nothing! I am a little upset that only 4 days into this purchase and around 600 cases of .223 the machines motor burned out. I having a replacement sent out by Hornady but if this happens again. I am asking for an exchange for their LNL ap press because so far I am not impressed at all with the case prep center. It did save my finger for a bit. But I did not like the speed at which it ran and cut way to slow in my opinion.

I would like to say that I own one of these, and for making 300 Blackout out of 223/5.56 cases this thing is a life and sanity saver. I agree that this isn’t for everyone but I have never had a regret about purchasing it. Also to make a nitpick point, not all the parts are metal. Mine has plastic gears in it that rotate the important parts off the motor. I wish they were metal but alas…the only issue I ever had with mine after about 3000 rounds of trimming 5.56 cases for blackout was that an allen screw loosened causing the cutter not to spin. But it was easily taken apart and fixed (and lock-tight added).

Looks as thought it could save time when you need to produce thousands of rounds on the regular. High Power Rifle Silhouette shooters tend to produce match grade ammo that is made by hand, automatic tools I have not seen. Even automatic powder measures are avoided due to their tendency to cut grains in half giving an inconsistent powder pour. Must say it is easier to do when the rounds needed for a match might be less than 200rd.

Given new shooting sports that engage at much closer ranges with more rounds, multiple stages per round the need to bring 1,000rds is valid. The time that can be saved by automating things like shell trimming/sizing, measuring powder and using a rotating press is not to be over looked.

IMHO there are different strategies to be used in reloading for each of the type of sport shooting.

I just take a file and file off the extra without the need for more tools. Works great for 223 and with my rra 223 it shoots under a half inch at 100 yds.

Too expensive, even at under $100.00, let alone the price they’re asking. Although, most new gun assholes will pay anything. I shoot every cal. and have been shooting for 50 years and a life member of the PGCA. Get what you can get, as it’s on its way out.

For the Hornady is .38, 30-06, & 50 cal?

A .38 is .357 and it is a straight walled case you don’t have to trim generally.

I have a Lee case length tool that I’ve used for well over 2000 rnds of 300 RUM, 270, 243 & 300 WM. None of the gauges have failed, it is easy to use and cost less than $50 for the hand cranked trimmer and several case-length gauges. I use an RCBS primer pocket cleaner and chamfer tool and get great and accurate rounds. After about 1500 rounds the primer pocket tool needs to be replaced. Big deal, less than $10. Seems like a bunch of money to spend.

It is a whole different class of tool. This is for precision reloaders.

“This is for precision reloaders”. Please don’t insult us with statements like that.

Belligerence will always be met with insults. And it we have to call in the Knights Who Say Kni, all measures will be accounted for and carried out. A guy who is cranking out 30-30 rounds to shoot 4 times a year doesn’t need a $400 case trimmer, and you certainly don’t need one for any straight walled case, which rarely if ever needs trimming.

Unless your loading, you know…. hornady 325gr ftx 45-70 that needs a case trimmed down a lot