To find out more, please visit Gas Block Genie.

If you have ever tried building an AR-15 style rifle from the ground up, it can be intimidating. A million little springs, roll pins and a number of things that need to go together in a certain way or at best, it won’t function correctly. The Gas Block Genie and Roll Pin Wizard go far in helping you.

Let’s start with the Gas Block Genie. If your gas port on the barrel is not matched up with the corresponding hole on your gas block, this can lead to problems. Ranging from the gun cycling sluggishly or even not at all. The Gas Block Genie makes the whole process easy.

Simply use the plastic Gas Block Genie like a stencil. First insert the Genie into the gas block, aligning the hole in the genie with the corresponding hole in the gas block. Next, mark a vertical line on the gas block in line with the centerline of the genie. After that, mark the edge of the gas block on the genie, showing how far forward the gas block sits on the genie.

Having accomplished the above steps, remove the genie from the gas block and line it up on your barrel, centering the gas port with the hole in the genie. Now make a reference mark on your barrel at the point that your gas block extended on the genie.

Now it is just a matter of placing your gas block onto the barrel and lining up the corresponding marks. This will ensure your gas block is lined up on both axes perfectly. Easy day.

It doesn’t stop there though, roll pins can be a nightmare while assembling ARs as well. The Roll Pin Wizard can really come in handy. The kit is comprised of a roll pin punch, spare spring and roll pin set as well as a pivot pin tool.

One of the biggest hassles with the lower receiver is the roll pin that holds the bolt catch in place. It offers numerous opportunities to mar your lower receiver, but not with the Roll Pin Wizard.

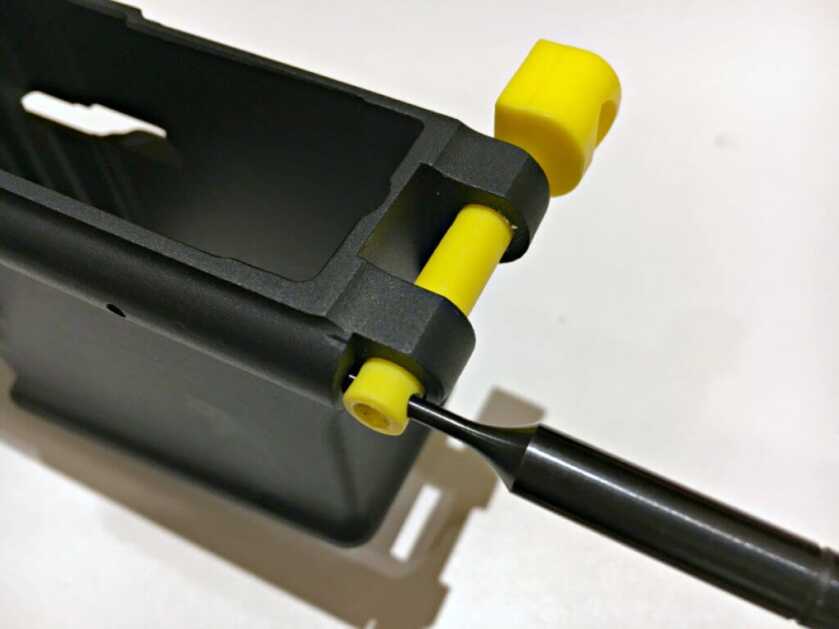

The Pivot Pin Tool doubles as a guide for the roll pin punch. You place the Pivot Pin Tool into the rear pivot pinhole of your upper receiver and then slide the roll pin punch through it. This lines the punch up perfectly to install the bolt catch roll pin.

The Pivot Pin Tool also can be used to install the spring and detent for the forward pivot pin. You install the Pivot Pin Tool into the receiver, slide the spring and detent through the hole, followed by the roll pin punch to depress it, and then simply turn the Pivot Pin Tool a quarter turn to capture the spring and detent. Then slide your pivot pin across the front, displacing the Pivot Pin Tool and capturing the detent.

Two incredibly simple tools that make short work of the more frustrating parts of assembling an AR-15. The Gas Block Genie can be found for $14.99 and the Roll Pin Wizard for $17.99

To find out more, please visit Gas Block Genie.

Both tools are reasonable approaches, not everyone has the dexterity or frequent project to develop it. Novel marketing, but these aren’t revolutionary; templates and slave pins have some history.

Not everyone has facilities to make their own such tools, 30 bucks isn’t prohibitive.

But I’ll wager half of us have a toolmaker/ skilled machinist working in his garage, just down the street. Why, you’re reading a submission from one right now!

I’m not really into “I built it myself from parts, It’s for sale now…”.

Someone using correct tools every time, different story – i.e. gunsmith!

I like the correct tool to do the job. Yes, I have an AR built on a bar stool too.

Doesn’t anyone else use a paperclip to line up their gas block? Just bend one end close to 90 degrees so the bent part barely fits in the gas tube hole. When it reaches the gas port, slide it down into the barrel’s port and keep it there until you tighten up the screws. Then, just pull it back up and out. Works every time for me and never had a problem with port alignment. I find large paper clips work best. Be careful to buff out an burrs on the end of the paper clip or live with scratches in the gas tube hole.

Really like the pivot pin tool. I always wonder why someone couldn’t do the same thing by drilling a hole in the middle of the pivot pin that is 90 degrees to the pin slot. I never got around to trying this but seems like it should work and there shouldn’t be any load on this part of the pin.

I started building AR’s a couple years back now. After the very first one, I started threading the bolt catch pin hole and using a screw instead. A little extra effort at the start Just makes the whole thing easier down the road. I cut my teeth building AK’s from flats up. That’s another animal altogether. I recommend folks starting out do the opposite and try their hands at an AR build first.