Accuracy Technology Comes of Age

by Paul Helinski & Ben Becker

|

|

It is hard to explain what the Straightjacket is. This is not an inch and a quarter heavy bench rest barrel. It is a regular rifle barrel, like the one above it, with a steel sleeve fitted to it that is filled with a proprietary media and capped. The muzzle break is optional and the rifle comes back with an separate crown protector. |

|

Our Straightjacketed Sako A7 ready to rock with the Vortex Razor HD. |

|

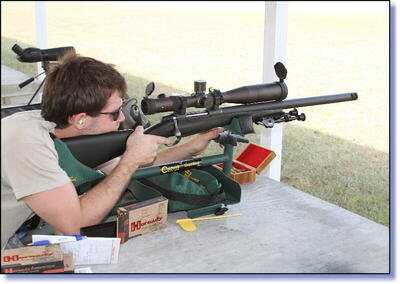

Ben sighting in the Savage Axis after it’s Teludyne treatment that is YIKES permanent. |

|

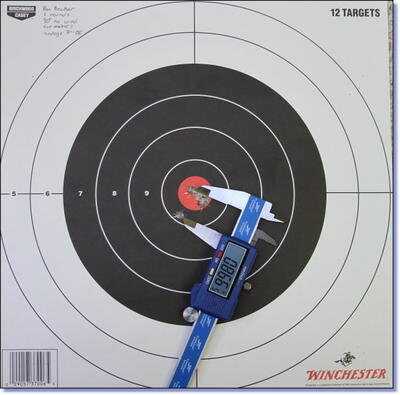

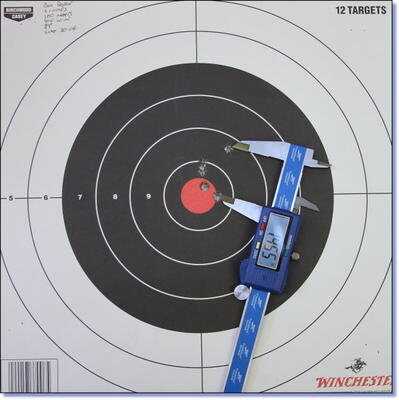

This was our best target from the Savage, .866 inches at 500 yards. |

|

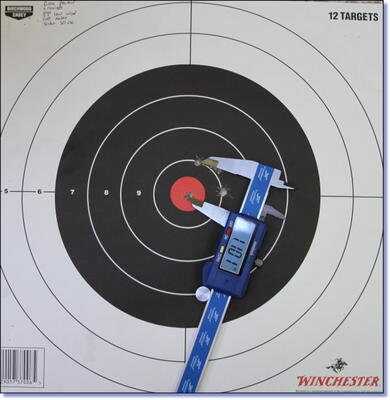

The best Sako A7 target, 1.10 inches at 500 yards. |

|

Ben with the lean and mean Sako. |

|

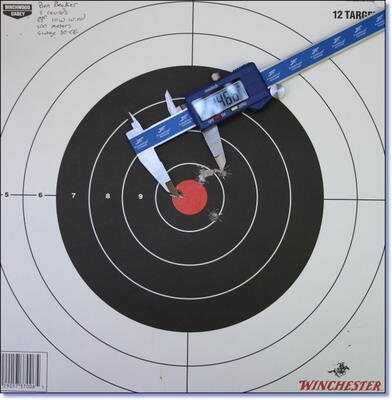

Five rounds from the Savage into 1.46 inches at 500 yards. |

|

Another five rounds from Sako into 1.45 inches at 500 yards. |

|

The Vortex Razor HD made this level of accuracy possible. I don’t think this could have happened with an everyday optic. |

|

When I first looked down the Razor and zoomed I was blown away. The reticle zooms with your zooming, and for very close it is joined by a very effective battle site. |

|

Tracy & Lanny Barnes, 2006 & 2010 Olympians in the Sport of Biathlon, competing in Canada with thier Straightjacketed Anchutz rifles. |

|

The top rifle is a Remington model 700 XCR in .300 win mag with a carbon steel StraightJacket Duracoated flat black. The bottom image is of a Winchester model 70 Safari magnum in .375 H&H magnum w/ a carbon steel StraightJacket also duracoated flat black. |

|

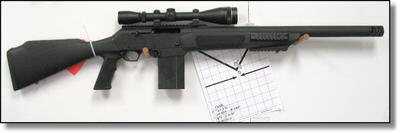

| FNAR .308 with StraightJacket installed and the 14 shot group target. |

|

| Alan Adolphsen shooting his Straightjacket equiped AR. In carbine length with 16” barrel has been described as boringly accurate out to 800 meters.. |

|

The AR-50 in the picture is the one tested with the 45 consecutive rounds and a mere 91 degree chamber temperature. It gained only 3.1 pounds with addition of the StraightJacket. |

|

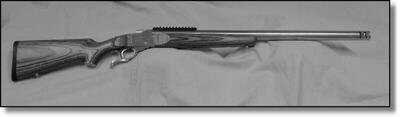

A Ruger #1 with a beautiful laminate wood stock and stainless action w/ polished stainless StraightJacket in .204 Ruger. |

When I first heard about the Teludyne Tech (TTI) “Straightjacket,” I was extremely skeptical. I have seen literally dozens of products come and go over the years that claimed to increase accuracy by “reducing barrel harmonics.” I thought that the Straightjacket, if I bothered to waste my time on it, would turn out to be just something else to throw on the pile with all of the bore treatments, weights, stocks, stock beddings, even something resembling electrical tape, that have crossed my path over the years. Nothing, in my opinion, could make a big difference in long range accuracy beyond what we knew up until now. If you want a rifle that would reliably shoot sub-MOA, you had to work up loads, build your own consistent match ammo, bed or free float the action, get the best trigger, the best stock, and especially the best and most expensive barrel. Teludyne wasn’t going to convince me that match grade accuracy would come out of a regular stock rifle with their “new technology.”

The most absurd about thing about the Teludyne story is what they want you to do with your gun. This is no “try it and see if you like it” product. They want you to send them your rifle, after which they will take it apart, press fit (at something like 50,000 pounds of pressure) a steel sleeve around your barrel, then they fill that sleeve with a proprietary compound, filling in all around your barrel. Then they weld a permanent cap on top, grind and sand your stock down to fit the new inch and a quarter thickness of your new “Straightjacket”ed barrel, then put the whole works back together and send it back to you.

Who in their right mind would send a perfectly fine but maybe not as accurate as I’d like it to be rifle out to be modified to such a degree, with experimental technology? This is a permanent deal. Love it or hate it, your rifle will never be the same.

Well it turns out that I was willing to do it, with two rifles in fact, and you aren’t going to believe the results. You are however welcome to come to sunny South Florida this winter and try them for yourself if you like. I know the discussion boards will be buzzing with disbelief as soon as this comes out and I welcome all comers. I feel priviledge to be one of the people who got a Teludyne gun “back when nobody knew about them” and I plan to keep my guns and shoot them a lot.

Rigidity and Heat

I was introduced to the Teludyne technology in May of last year at the NRA show, while setting up the GunsAmerica booth with our crew. Two gentlemen approached me and offered me a brochure about a new accuracy technology that one of them, a Mr. Alan Adolphsen, had invented several years before. Instantly visions of the electrical tape guy flashed into my mind. I tried to blow them off, but there was an earnestness to them that made me stop what I was doing to listen.

The other gentleman, Mark Hatfield, explained that Mr. Adolphsen had discovered that accuracy in rifles and the improvement thereof was not what we have thought it was all of these years. The phenomenon all of us know as “barrel harmonics” existed, but there was no mystery to it as most of us thought. “Anyone who has ever cut a gun barrel, he explained, knows that there is no way within the bounds of our manufacturing capabilities to make the hole perfectly center, all the way perfectly through the length of the barrel. The steel itself has different densities, however slight, and this effects the resistance to the cutting tool. “

Even the most precise barrel maker is going to have some minor inconsistencies in straightness and wall thickness of every barrel. Under normal conditions, if we fired only one bullet at a time from the gun with complete cool down in between, this wouldn’t be an issue. But as the gun heats up, the varying wall thicknesses push and pull the barrel along its length, because it can’t by the laws of physics expand and contract evenly. This effects accuracy, the phenomenon we call “barrel harmonics.”

“All of these years, “ Mr. Adolphsen piped in, “we have been obsessed with perfect loads that we thought “matched” the barrel. We have been fiberglass bedding our stocks and free floating our barrels to relieve the touch points along the barrel length that theoretically made our barrels pull themselves out of perfect harmony. We have invented the most sensitive and ergonomic trigger systems and gun stocks to reduce as much human error as we can. But all the while we ignored the simple fact that the cutting tool wavers during the manufacturing of our barrel, and when we heat up that barrel by firing more than one round, the steel contracts and expands, exacerbating the variations.”

The Straightjacket is designed to take away the heat. In physics and electronics parlance, the Straightjacket is a “heat sink.” They won’t tell me exactly what is in that mixture they pour in the sleeve around your barrel, but I suspect it has some aluminum or copper in it. Both metals blend well with others and are more heat conductive than steel. By the laws of physics, if you bond a piece of aluminum of copper to a piece of steel and heat up the piece of steel, the heat will race to the other metal, because it offers less resistance to the travel of the heat. The heat will then live in that metal and bleed off into the air before it returns to the steel.

In practical terms for the Straightjacket, this means that you can put five quick rounds through your bolt rifle, open the bolt and stick your pinky in the chamber and it will be cool, while the outside of the Straightjacket will be hot, but not as hot as your bare rifle barrel would be because of the increased surface area that the Straightjacket provides. The jacket material sucks the heat away from the rifle barrel itself. Therefore the cutting inconsistencies in the barrel that Mr. Adolphsen have explained are never amplified, and your rifle shoots more accurately. To quote Teludyne, “the Straightjacket completes the rifle barrel.”

Understanding the technology breaks down to rigidity and heat. The sleeve of the Straightjacket is 1 ¼” thick and resembles a heavy barrel rifle, but is much lighter than a comparable thickness solid steel barrel, which would be around 12 pounds. The StraightJacket Barrel System adds about 1.5 pounds or less. The inner barrel (you remember, the one that used to be your rifle barrel), is bonded to the poured in media material, making the whole unit one, and adding a great deal of rigidity, preventing any real flex. Then you factor in the heat, or lack thereof. The barrel stays cool, so it never goes out of whack. I have a friend who hunts prairie dogs and he is sending his fluted custom .22-250 dogtown rifle to Teludyne, because, in his words, he “can’t shoot ten rounds out of the gun without the accuracy going south.” With a Sraightjacket fitted rifle, your accuracy stays constant, no matter how many rounds you pound through the gun.

The Guns, the Straightjacket, and the 500 Yard Targets

I sent Teludyne two rifles, both of them are in the companion article to this piece, Out of the Box MOA. One is the Sako A7 in .30-06 and the other is the Savage Axis in .30-06. Both rifles performed in exemplary fashion at 100 yards with no Straightjacket, so Ben took them to the 500 yard range in Tampa to see what they would do with their new and very permanent heat hungry barrel sleeves from Teludyne.

For those of you reading this who will actually make the jump and send your guns to Teludyne, the company seem to be very together as far as getting you your gun back in a timely manner. It was only a matter of weeks for two guns. Teludyne claims that they can currently modify 100 guns per month, with the facility space for 4 times that production level.

For this article, I should mention, I elected to not get into the AR-15 side of the Teludyne story. I feel that a bolt gun has much fewer variables in it and that the technology needs to be measured standing by itself as much as possible. I also didn’t send a wood stocked gun or a stainless steel barreled gun, all of which the company can easily handle. I have included some pictures, provided by the company, of other projects they have recently completed to give you an idea of the custom nature that they operate under.

Prices for the Straightjacket on a carbon steel bolt gun start at $349. You send in your rifle and they send it back. Stainless, aluminum, and the AR configuration are all varying prices, but not far away, and you can buy a whole upper or complete rifle from Teludyne in whatever rifle you would like. As you’ll see in a picture here, they recently did a Ruger #1, which is one of my favorite rifles ever, and not a gun that people modify lightly. The entire price list and contact information can be found on the Teludyne website of course, as well as the process they require to send in your rifle.

You will notice that there is more than one target here from each rifle. If there is something I would like everyone to take away from this article it is that Ben and I went into this as skeptics and did not cherry pick the results. Target after target after target came back on both rifles with both guns shooting into an inch to an inch and a half at 500 yards, and it didn’t seem to matter how many rounds of standard Hornady brown box or Hornady Superformance we put through the guns. In total Ben shot 160 rounds through two guns, some at 100 yards to get a baseline, but most at 500 yards in light to no wind on a 90 degree Florida day.

The optic Ben used was not the same as for the Out of Box MOA article. Vortex was kind enough to send us their $2500 MSRP (street price under 2k) scope called the Razor HD, in 5-20 power X 50mm. We are doing a full review of this incredible piece of technology itself apart from this article, but the results here have to be taken in context of what scope we were using as well as to whether you could duplicate the results. Ben is an accomplished US Army Sniper and can shoot like nobody’s business, but the Razor has a reticle that grows and shrinks as you zoom the scope. So at 100 yards, the reticle is covering the same percentage of the target as it is at 500 yards. It also has a fine tunable and viewable parallax adjustment with comprehensive directions on how to correct the sightline of the scope to the shooting line of your rifle. Our friends at Vortex made a huge difference in the hard data we were able to collect for this article. The scope is amazing.

I’m not going to bore you with calculating the percentage of one “Minute of Angle” or MOA that both the Sako and the Savage shot with their Straightjackets. The Sako ranged from an inch to an inch and a half reliably at 500 yards, and the Savage even had a couple targets under an inch. Both guns are essentially low cost hunting rifles with decent but hunting triggers, and have hunting stocks. The ammunition was not fine tuned for the guns by a hand loader. We went to Bass Pro and bought it off the shelf just like you would. Granted we didn’t test either gun without the Straightjacket and with the Razor HD, but to say they improved would be a significant understatement. You can pay $2,000 plus for a custom made accurized rifle and not get these results with factory ammo.

Competition & The Biathalon Twins

One of the reasons I so readily sent two fine rifles away to be ‘jacketed was because the Teludyne technology is not actually a new and experimental product. It was invented in 2004, but instead of rushing it to market (because Mr. Adolphsen knew he had something real), the Straightjacket took the long road to commercial availability. It had to be patented, and long term financing had to be secured so that the company and not just the product would be solid for the long haul. The gun buying public and the gun industry in general doesn’t accept anything new very easily. As my friend Michael Tenny from Cheaper Than Dirt once told me, “it took the gun industry 20 years to adopt screw in chokes.” In our industry and in our gun people mindset, The Straightjacket could spit 24k gold quarters every round it fired and it would still be a long time until it gained wide acceptance.

That hasn’t kept it from finding its way into competitions the world over since it did go commercial in 2009. Nobody is keeping coherent records of what they have won, but according to Noel Lasure, their VP of marketing, they have stock M77 Rugers out there winning bench rest NRA High Power competitions all over the country. At the FN sniper competition in Maryland this year, the Maryland State Police team shooting StraightJacketed rifles came in 4th in the grueling unknown distance competition and beat elite sniper teams from all branches of service and federal law enforcement as well as Special Operations units.

Perhaps the most notable story is that of Tracy and Lanny Barnes, the US Olympics Biathalon Twins. They are using Straightjacketed Rifles and are winning all sorts of competitions and setting new records. They were 2 of 17 to ever shoot perfect scores in the North American Cup and they did it with Straightjacketed rifles. This is part of an email that they recently sent to Mr. Adolphsen after returning from a match in Canada.

“We wanted to let you know that it is very safe to say that the Straight Jacket is extreme cold certified. We had our barrels in below zero temperatures for up to 2 hours and the groups were as tight as if it was 60 degrees! We don’t see this very often with the anschutz barrels and many people were having problems with their groups spreading because of the cold. We have been extremely impressed with the size (or lack there of) of the groups with the straight jacket! We were

putting 5-10 rounds right on top of each other. We couldn’t be more pleased. You guys really have a good thing going. Also a warning… don’t be surprised if all of the U.S. and Canada (and soon europe) will call you up in the spring and be willing to pay big money to have the TTI installed! We had so many people asking about it and they are interested and willing to pay a lot for such a great product.” -Lanny & Tracy Barnes, US Biathlon Team

Not Just for New Rifles

It is hard to just dispose of things that you thought you knew in life, things that have governed your paradigm and been key factors in decision points (W pun intended). To believe in the Straightjacket is unfortunately a case where you have to stop believing and parroting aspects of accuracy that you have been taught and perhaps have even taught to others yourself. One of those is the concept of a “shot out” barrel. We have all relegated guns to the back of the safe or sold them off for cheap because we felt that the accuracy potential for the gun is gone. I know shooting competitors who consider 1500 rounds the limit for a service rifle match, and will actually change out the barrel before waiting for the accuracy to go down.

That is why one of the most disturbing things that Mr. Adolphsen taught me on that exhausting NRA show day in May was that the Straightjacket could make a tack driver out of your old and worn out deer rifle. I personally haven’t seen this, but the claim is that you can send them an old gun, with poor rifling, that you consider to be “shot out” and they will Straightjacket it and you’ll get it back shooting into an MOA. Apparently the rigidity of the bonded jacket itself takes the flop out of an old barrel, and contrary to what we believed, it is floppiness and not bad rifling that causes the majority of the problem with an old gun. I may send them my old Mosin 91/30 and let them show me.

Torture Test

No, first off I can say that I am not going to go outside and beat my Straightjacket rifles against the nearest palm tree. But I feel that there are valid concerns about the durability of the Straightjacket once it is on the rifle. Teludyne fully expects the military and police departments to adopt the Straightjacket, and I wondered what the thing would do if you tripped in urban combat and whacked the thing at a 90 degree angle on a concrete block wall. Is the whole works just going to crack inside and slide off the front of the gun? It is, after all, not welded to your barrel. The sleeve is press-fitted, or swaged, onto the front.

Teludyne claims that in the over five years from invention to commercial application, they have submitted the Straightjacket test guns to all sorts of abuse you could imagine, and there was never any evidence of internal damage or failure. The have pounded on them with sledge hammers and then taken cross sections of the barrel. Nothing. No cracks, no separations, and certainly no systemic failure.

To quote Noel Lasure, “Using Blow torches, chop saws, and big hammers we have tested the StraightJacket to withstand the abuse we know a Soldier would give their rifle and in every case the rifles have shocked us by surviving.”

Extreme Stories for an Extreme Invention

You can see from here what Ben and I actually tested. But I feel that the Straightjacket story has a lot yet to be told, and it could end up being a very long story. It seems that the heat sink nature of jacket material has had unexpected results in guns that have been shot a lot since being Straightjacketed.

- USSOCOM re-barrels an AR-15 pattern rifle after 6000 rounds. Teludyne has an AR with far in excess of 6000 rounds, upwards of 10,000 rounds, with no noticeable throat erosion, and a great deal of these rounds were fired in full auto mode. This could be the end of life expentancy for competition rifles. You have one gun made and it lasts forever?

- At a recent 50 BMG shoot, a StraightJacketed Armalite AR 50 was shot for a 45 round sustained fire test, using Military surplus machine gun ammo. On an 86 degree day the chamber temp never got above 91 degrees. While every other rifle on the range were being left to cool after 3 or 5 shot groups for fear of damaging their rifles and loss of accuracy.

- At the recent big 3 media event in Kansas the only semi auto rifles that didn’t go down from all the shooting were the ak series guns and our StraightJacket AR rifles. When the heat is reduced at this rate the actions stay cleaner longer allowing for longer shooting intervals.

- You can empty a 30 round mag on an AR full auto and still put your hand around the barrel.

Can My Gun Be Straightjacketed?

Most rifles can indeed be Straightjacketed. All bolt guns, regardless of barrel and stock material are candidates, and all AR-15 pattern rifles. Most single shot rifles can easily be Straightjacketed, as you see with our friend the Ruger #1. Teludyne has made a version for an AK pattern, but it is not in commercial production yet. Likewise for the FN-FAL, with great results. The M-14 is a solid no, as is the CETME and HK-91 tactical rifle pattern.

Whether your gun should be Straightjacketed is of course up to you. But I agree with Lanny and Tracy, this isn’t going to stay a secret much longer and when demand comes up, even at four times current production, the price is going to come up. Get your gun done while they are still having to individually sell people on the technology. There is no planned price increase as of today, but you never know.

There is also a serious risk that one of the big gun makers will buy the company. I know that several of the “Big 5” have been looking at them for licensing possibilities, and we know from experience that for one of those Big 5, money is no object. If Teludyne gets bought, there will be no telling if you will be able to still retro-fit your rifle, or if you will be forced to buy one brand of rifle, in whatever configurations they offer.

At present Teludyne is not selling whole guns, but if you want a whole gun you can request it. They will purchase the gun from a distributor and Straightjacket it for you, then send it to your FFL dealer for legal transfer. If you feel like you have questions, feel free to call them. They are still answering their own phones. Contact details are on the website.

I will trust that this “technology” improves accuracy of rifles that shoot poorly. This technology appears to be an attempt to “poor” a bull barrel around a sporter barrel.

Thermodynamic laws simplify why this technology, as well as bull barrels, dissipate heat quicker. Heat will move much quicker through metal (conduction) than through air (convection). A larger chunk of metal is also a larger sink to absorb the heat, that’s why it takes longer for a bull barrel to get hot than a sporter barrel. The increased surface area of the bull barrel will allow quicker transfer of heat to the ambient air as well. Because there is a significant temperature gradient from inside of a bull barrel, to the outside, the outside of the bull barrel is effectively stiff enough to resist barrel deflection caused by the higher internal temperature. The thinner sporter barrel cannot offer the same resistance.

I will opt against this technology and just buy well made products for my long range work.

I own 4 Savage rifles.

1. A 110FP 25-06 bull barrel with 1600 rounds through it. Still shoots 0.4 moa average 5 shot groups at 500 yds with 75 vmax (varmints) AND 110 accubonds (deer). Just last week a woodchuck was exterminated at 760 yards.

2. A 16F 270WSM that shoots 0.6 moa average 5 shot groups at 500 yards with 110 Barnes TTSX (deer) AND 140 accubonds (elk).

3. A 14Classic 308Win that shoots 1.2 moa average 5 shot groups at 500 yards with both 130 (deer) and 168 (elk) Barnes TTSX’s.

4. A 25WVTH 222Rem that shoots 0.5 moa at 500 yds with just about anything you feed it.

Nothing done to these rifles except adjusting the trigger to the lowest pull weight, and a skim bed job on the 270wsm (all done by me).

5. One Remington 700 BDL laminated 270wsm that was bedded and floated. 0.8 moa to 500 yds with 150 BT’s (deer) and 130 Barnes TTSX (elk).

6. One Ruger 77 compact. 0.7 moa to 500 with Berger 87 Hunting VLD. Nothing done to this rifle.

Yes, I spent some time on load development, but I get a lot of shooting practice out of it. I would dare say that most of the rifles that were “fixed” by this “technology”, in their original condition probably would have equalled the performance of my rifles with a little work, patience, and practice, and without the “magic”.

No it all…What if the material poured between the barrel and straight jacket actually moves heat at an acellerated rate, and therefore leaves the inner barrel much cooler than a single bull barrel ? Perhaps there is more going on here.

I was looking at a Min 14 Ranch 203 cal It has this a screw on device covering the end of the barrel about 8in long, like a cone. I just wonder could that be a heat shrink or could it be made to work that way by an after market material?

Bought a Straight Jacket for my 1988 Ruger M77 MkII .270 Win in July 2012. Was a decent shooter when new, but in the past few years had opened up to over 4″ at a hundred yards. I read the Guns America and a couple of other articles as well as Teludyne’s info and then bought one. Because of problems with scopes I was unable to get a good set of rounds through it until September. It only took a couple of loads to find the right ones for the gun and I was immediately impressed. My 4″, five-shot group became a one-hole group at 100 yds with Barnes 130 Gr TTX at about 2900 fps. My 150 Gr Berger HVLD’s at 2750 fps weren’t as tight at 100 yds, but at 620 yards both sets of bullets hit repeatedly on the 16 oz water bottles we were using as targets. We only had 20 rounds of each load but even in 90+ heat the gun repeatedly stayed on site with little cool-down time. My scope was just a sub $200 Sightmark 6.5-25 X 50 Triple Duty.

One other point: this gun has always been very fickle with the different rounds put through it. It never would shoot Remington Express, but Federal Premiums were spot on. Later, before the straight Jacket, nothing would shoot consistently through the gun, likely a consequence of the repeated cycle of heating and cooling over 25+ years of shooting. I’ve gotten very picky with my loads, now, but have noticed that even the cheap Sierra rounds shoot better in this “new” system. I am very impressed. Yes, the system did increase the weight of the gun by about 1.5 lb, but it is nicely balanced, now, and the muzzle break has the recoil to about as much as my old Remington Speedmaster 22LR.

The cost has “blossomed” to $650 + shipping. About the same as a new rifle. Is it worth it? You bet.

Ooops, sorry. I thought that I was leaving a message for Teldye Straightjacks.

I have a Savage Precision Carbine chambered for 223 Remington. It has a 20 inch bull barrel with a 1:9 twist. The rifle weighs 8 pounds, with most of the weight towards the muzzle. I have both of my rotator cuffs torn and I have carpal tunnel in both wrists. I was thinking about your sleeved barrels. I would like to keep the 20 inch length and 1:9 twist, and no muzzle break. Could you give me an idea of how much weight would be shed, what it would entail and cost.

I compete with an Anschutz Exemplar, 14 inch barrel. It will shoot lees than 1 inch at 100 yards. How much weight will the Straightjacket add and will it improve my groups?

Thanks Johnny B

.

Call teludyne

I have the distinct honor of owning two early prototypes of this system, the inventor is my friend and i did not need much convincing once i saw the truth of it. my m-70 has a long and storied life as a state police patrol rifle, it saw many years of service before comming into my possetion, once modified this rifle has consistantly shot well with any thing i can close the bolt on, {and I have and can put ammo threw this piece that would make an A-K puke} it is a 1967 pusher long action with a 1-12 twist 21 inch medium taper barrel chambered in 7.62 nato.

[ neet huh?} the rifle shot very well when i origanaly purchased it,over time it had opened up to 1.6 MoA with great ammo, {5 round groups}. once treated i was stunned to see the difference the strait jacket made in accuracy,in the past shooting long rapid strings would have resulted in flyers out to 6.6 MoA even @ 100 yrds.so what to do? we lugged out the old M-70 to the shops own private table, and set out to prove the conversion. For the test my friend dragged out 78 rounds of pure crap, 1978 vintage egyption machine gun ammo. its dark black patina told any one looking at it,it was very old. so with a100yrd target at the ready we comenced to loading firing and reloading all 78 patheticly tepid, putrid,nasty, {you get the idea} rounds of ammo as fast as two people could humanly do it. when we were finished firing the first thing we tested was the barrel temp, not having a digital temp meter at that time we just did it the old boy method of grab and hold and to my amasment the barrel was what i would describe as room temp warm, not bad considering in the past you couldnt touch it after 20 rounds, so lugging it by the barrel we strode down to the paper and the scope had told the story so we new the group was better than we could have hoped origanaly, however the tape confirmed all 78 rounds stayed inside 2 inches. I am eager to see just how good the old girl shoots now that i have resquared, and recrowned the muzzle I will get back to you soon.

Best…

Donnie Heald.

Great story Donnie. Thanks. -ph@ga

yes …but a fal isnt a pelet rifle ..no offense …;)…never built a fal yet that wouldnt touch holes at 80 to 100 .all in the building ..the rifles bbls are properly machined at the factory ,they shoot straight …its the mid west master smurfs that screw em up …the two idiots above dont know there is a difference between thread “PITCH” and TPI yet …truly UNINFORMED and UNQUALIFIED …they wouldnt pass a 9th grade machine tool class in orygun …

build em the RITE way …they shoot verry well ..for what they were designed to do …double taps on a 400 17″ gong is about as good as its gonna get …

Oh! I get sub moa (5/8th) 100 yard out of my $179 marlin .17 HMR with a $59 Bushnell 3-9 scope! So I have a hard time buying into the accurate rifle hype!!?!?! The marlin does have a bull barrel though!

Hey Guys,

I’ll be sending out a rifle soon! Just had a thought though…..does a thinner or heavier barrel seem to act any differently?

Could this be done with something akin to just a steel sleeve? Does there seem to be any perfect barrel diameter to start with?

My thought was that maybe a thinner barrel would:

#1. Cut weight

#2. have less steel to hold heat

Thanks

http://community-1.webtv.net/ggiilliiee/GGIILLIIEESRAIL/

ya want an accurate FAL ..dont cut the bbl unless the smith has the PROPER tool and actually knows how to use them …

open the rails so your ammo isnt going thru the rock chrusher ..FAL are notorious for beating the hell out of ammo on the feed ..sheared off tips ..bullet actually shoved back in the case from ramp crashes (modifying stops all that)…

not dong the shoulder shaving to the correct point of getting your 125 flbs of torque ..leaning fat bubba on a cheater bar is just bending the threads over and tweaking the end of the receiver ..NO vise will stop it …most never even check on the rock for flatness after …”master smiths” as it were … other than hacks out there your good ta go …

verry nice …but id drop the PROTOTYPE thing …weve been doing that to HK and the like for about ten years here in ole orygun …nice work though..kinda like the ole dan wessons shroud that secured at both ends of the bbl .same thing different day

but with folks like ARS /Arizona NO Response” (jammed)and the miracle Moses at cmp-uke who cut into BBLs and get T.I.R…(they dont have the tube testers to even check to find out one way or the other..guessing as it were )..we call em novices here in the machine shops ..

..then they cant figure out why the bullets is going off 3 feet at 50 yards …(actual post by ARS in the FAL files ) ..a real idiot ..

sooooooooo, when ya got bozo folk like that cuttin down BBLS ..your unit wont do a dam thing ..just so your customers know before they find out the hard way

GGIILLIIEE

I have just received a video that I posted to my YouTube Channel of a 300 Win Mag with and without a StraightJacket. You can definitely see a difference. Here is the link to the video, http://www.youtube.com/watch?v=HIRIyWWz3Fk

Sean Smith

I have seen this done before around 1986 . I was at the Second Chance shoot and a Gentelman at the rifle Range had a Ruger Mini 14 and a HK 22Mag semi auto with this procedure done to it. I am VERY interested to know if it is the same Gentelman. The Rifles were VERY accurate and I could run a 20RD mag at speed through the mini and hold a beer can at 200Yds. The sleeve he had was not press fit but rather it screwed on like a Dan Wesson bbl and PULLED TENSION on the bbl and the sleeve was filled with regular antifreeze. He made me a beleiver and this sounds like a great project. J.Michael

I was wondering if a lever action rifle can be done. I currently have a new Marlin in .45-70 and an ooollddd Winchester 1894 in .32 WS.

Its Monday night the 27th and found the info on the Straightjacket on my computer.It was great to read about the Teludyne process and its sucess as I await my rifle back on Jan. 19th. Anxious to shoot it after what I have read here. Happy New Year & good shooting fellow firearms enthueists,

My son has a Ruger M77 in a stainless steel .308. Can you put a Straight Jacket on there for him if I send the gun? How much do you estimate the costs and time involved?

Herb

I have a curious question. I understand the reluctance to work with the M-1 / M-14 rifle (Gas tube issues). But why the reluctance for the HK-91 action? There is nothing external to the barrel to interfear with the use of the Jacket. And these earlier rifles with hammer forged barrels would make excellent subjects for this sort of improvement. Unless the issue is the chamber diameter (with the issues of the width of the locking mechanism).

To Dimitri: If your group is primarily left to right it sounds like trigger pull. It might be that you’re not used to that trigger or that you’re not using the pad of your trigger finger but the tip or the joint instead. If the group is up and down it would be your breathing.

Regards and good shooting,

Seekers

How is the Straightjacket fitted to an AR15? There’s a front sight tower/gas block and a gas tube in the way.

the front sight tower is removed, and the gas tube is set far enough back to not matter.

Do you have a photo of this? There still needs to be a gas block. Unless you have an alternative bleed off.

ALL THE DIALOG IS VERY INTERESTING. I DON’T HAVE THE TECHNICAL BACKGROUND AS MANY OF YOUR CONTRIBUTORS SEEM TO HAVE, BUT I AM STILL INTERESTED IN GETTING TIGHTER GROUPS. BACK IN THE 60’S I SHOT A QUICK 10 SHOT GROUP MEASURING 3/8 ” AT 100 YDS WITH MY .244 REM AK-IMP (40degree). I am near 70 years old NOW, LAST YEAR I DECIDED I WANTED TO TRY SOME LONG RANGE SHOOTING, 500 TO 1500 YARDS, SO I DUG OUT OF MY CLOSET A REM. MADE O3A3 I BOUGHT FROM THE NRA FOR $14.94 BACK IN THE 50’S. IT’S IN VERY GOOD CONDITION, HAS NICE 4 GROOVED BARREL, STAMPED AS TESTED FOR EXTRA PRESSURE ?. I PUT A BLACK POLY STOCK ON IT, FIXED THE BOLT HANDLE AND TOPPED IT OFF WITH A LEUPOLD VX-3,,6.5X- 20×50 LR TARGET SCOPE WITH VARMIT RETICLES. REPLACED TRIGGER WITH CHEAP TIMNEY(2.5 LBS) I ONLY GOT OUT TO 600 YARDS, BUT MY LAST DAY OF TESTING IN OCTOBER, TEMP 35-40 DEGREES, WIND 15-20 MPH ACROSS BULLET PATH WITH RAIN AND HAIL IN MY FACE, I SHOT A 17 SHOT GROUP THAT MEASURED 4″ X 9″ GOING L TO R ACROSS AIMING POINT. I WAS USING SIERRA’S 190 GR HPBT MATCH BULLETS AND ALIANTS NEW(TO ME) R-17 POWDER GETTING ABOUT 2900 FPS. THIS GROUP IS MY BEST( ACTUALLY MY ONLY, BECAUSE I QUIT THIS AND STARTED GOOSE HUNTING), I REALIZE ITS PRETTY SLOPPY COMPARED TO SOME YOU MENTIONED. QUESTION: BESIDES LOTS MORE PRACTICE, DO YOU THINK THE STRAIGHT JACKET WOULD TIGHTEN MY GROUPS FROM MY O3A3? AND BY HOW MUCH?

ANY COMMENTS WOULD BE APPRECIATED, THANKS, DB

Yes, I think it would greatly, more than anything else you can do.

WAIT A MINUTE!!!!!!

“Granted we didn’t test either gun without the Straight Jacket and with the Razor ….”

You mean there’s NO COMPARISON here?!?!? If you didn’t test the rifles with Razor Scope BEFORE the Straight Jacket was installed there’s no control group! Right???? How do we know it made any difference at all? How do we know you couldn’t have done BETTER with the Razor installed on stock, unaltered rifle? WE DON’T! It’s shear conjecture.

Are the second group of 2 targets control targets shot BEFORE Straight Jacket installation? If not where are the targets shot with STOCK rifle prior to installation? Come on guys, you really ought to know better than this. You’ve expended a great deal of effort, time and resources without telling us anything FOR CERTAIN. That’s a real shame too because this is a very interesting subject. Precision shooters thrive on empirical evidence. Your CONJECTURE, though likely correct, just doesn’t cut it. We need to see comprehensive test data (Control Targets).

Yeah we kinda realized that afterwards, but whatever. Then don’t send you rifle out. Both rifles have test data at 100 yards with a Leupold. If they were shooting better it would have shown it.

Interesting product and description. However, heat does not magically move from one material to the other unless there is a thermal gradient. The original barrel will allways have to be a bit warmer than the heat sink at the point of the bond for the thermal energy to move from the barrel to the heat sink. I’m not saying that this product will not keep the original barrel cooler, I just want to point out the physics and get away from the “magic” factor implied in your description.

Do they match the receiver to the finish on the barrel? This looks like a process that would replace re-blue and improve the rifle WOW a real winner? I have a .270 Weatherbe Mag that could be a candidate?

Yes, they are very good from what I have seen about making the gun look fabulous.

Can an SKS be Straightjacketed? Or for that matter is it safe to say that all or most bolt action guns (rifles) can be Straightjacketed? And then all semi-auto’s are not due to the gas operation?

Larry

I don’t remember exactly Larry but I think they have done one. It isn’t something on the website, but call them.

Seems silly to run a feature on the barrel jacket without a before and after test at the Same Yardage. And the moa error , it is not an exact inch per 100 yards…hope the standards improve for this journal. At least it is free

Paul,

I was actually the first guy you talked to at the NRA show, and brought Mark and Al to see you. Glad you liked their product. You mentioned that you are thinking about sending a Mosin 91/30 to them for a straitjacket… I am the proud owner of the prototype known as the “Mosin Olympic”. I had a 91/30 that I Ieft at the shop one evening, making a joke about “doing a project with it”. When I came back the next day, Al had cut 9″ off the barrel, put a straitjacket on it, and was getting ready to cut the furniture for the gun. As a really good arsenal refinished gun, I told him that I hated to mess up that good wood, so we found a cherry blank and cut a custom stock for the gun. We moved the bolt handle so that we could weld a scope mount onto the action, and then reinforced the action of the rifle with some “mechanical tricks” that Al knew. A brass insert made from a .45 casing was put under the trigger to make it act like a single-stage trigger, and the addition of a $95 Field and Stream scope (6-24×50) from Dick’s Sporting goods, and I have a rifle that shoots .375″ groups at 100 yards with some of my handloads. With Silver Bear 203 grain ammo, I get 1.5″ groups consistently, and with 174 grain Silver Bear, I get 3″ groups at 300 yards. When people look at the .375 target, they almost always ask if that was “cold bore”… and I let them really have it… the .375” group was shot after shooting 100 rounds of 7.62×54 mixed box and handloaded ammo in an hour. It was the last 3 shots of the day.

I’ve shot thousands of rounds through my Mosin since changing it’s profile to the Olympic… and it just seems to get better and better. Wonder what it’d do if I didn’t have cataracts and I had a good scope on it?

OMG what a story huh. We’ll see where they end up with the straightjacket. Hopefully not the same place the guy ended up who build a car engine that got 75mpg.

Hi there ,I am in Australia, retired Toolmaker ,and manufacture harmonic barrel tuners, but only for small Caliber , up to .222 and screw on type, have some pretty good replies from customer, and cost of one is absolutly reosanable, thread are 1/2inch 20TPI, and 1/2inch 28 TPI

Harmonic Barrel Tuner do work, take my word for it,been experimenting for a long time, regards Walter

So what is superior to a M1a/M14? Those jamm’ in AR style dirty rifles? Seems to me it is hard to find a better 308.

And please explain/ Seems like those boys are going to gas pistons = old technology huh?

1 Why accuracy is not degraded by copper fouling?.

2 Statement about steel is untrue on a lapped, stress relived bbl aka Krieger. Also if steel varries heating up it will also very in heat dissapation

3 A BBL with a shot out crazed throat and a loose muzzel is not going to shoot many rounds without fouling.

4 spend some years reading Percision Shooting on steel bbls

with the M1a/M14, there gas tubes go to far down the barrel to be worked with. As for the copper, fouling of any kind usually sticks to the metal of you’re gun because of the heat, without the heat there’s just no build-up.

I would just like to thank everyone involved with this site for your kind words and attention. If there are any questions or concerns about the StraightJacket Barrel System that I can help with, please do not hesitate to ask.

What improvement did the Straightjacket make to the Sako and Savage at 100 yards, compared to their pre-altered performance? I am wondering if the improvements the Straightjacket provide are only seen beyond 100 yards?

Why is the M14 “a solid no”. I have an M1A which is one of my favorite rifles.

Ed Wilmsen

The gas tube is a problem. They consider it technology of antiquity.

I would like to offer the authors of this article the opportunity to check out one of the fastest-growing shooting organizations in the country- Project Appleseed. While we are a nation-wide organization, with a presence in just about all 50 states, this program is growing by leaps and bounds here in Florida.

For the week of December 12-19th, 2010, Project Appleseed will be instructing average American rifle owners in the finer points of shooting to a 4MOA standard at 500 yards, (4MOA @ 500 yards = 20″ Target) which is traditionally known as the “Riflemans Quarter Mile”, or the “Infantry Half-Kilometer”. This feat of marksmanship prowess can be done by a “Rifleman” with a standard, rack-grade rifle, and ball ammunition, from ‘field’ positions, with iron sights. Project Appleseed teaches the fundamentals of rifle marksmanship, and can teach ANYONE how they can better their groups. From never-shot-a-rifle-before pre-teens, to NRA Highmasters & professional snipers, our program of instruction has resulted in smaller groups and better consistency from all manner of shooters.

We offer our classes tuition free to women, responsible persons under 21, Active-Duty military (including National Guard and Reserves) and duly-sworn Law Enforcement Officers. The cost for two-day attendance for all others is a paltry $70. The cost for a week-long “Boot Camp” is a mere $200. Range fees, ammunition, and rifles are the responsibility of the student.

For more details on this outstanding organization, including a link to our nation-wide schedule of events, please visit our website, http://www.AppleseedInfo.org

I would like to personally invite the authors of this article to come out and see Project Appleseed in action- we’ve got a number of events coming up in Florida, and the authors are welcome to attend any (or all) of them! Simply email me, and we’ll get the ball rolling.

Eric McCabe

Florida State Coordinator

Project Appleseed

http://www.AppleseedInfo.org

Email: [email protected]

I’ve been planning to get involved with you guys Eric. Thanks for your comments here. I may send Ben out and will email you from my private email.

Correction: A minute of angle is not 1/360 of a circle. That’s a degree. A minute is 1/60 of a degree

or 1/360 x 1/60, or 1/21,600 of a circle. A second is 1/60 of a minute.

Yea already changed it Charles. Thanks. Alas if that were the only signs of an aging brain… -ph

This product is going to quickly become THE standard for competition-level rifles. The results from ‘straight-jacketing’ a ‘worn out’ rifle, have been astounding. If you are serious about extreme-range accuracy, and would prefer if sustained fire didn’t mandate enlargement of group size, you owe it to yourself to check this process out.

[quote]A minute is 1/60 of a degree[/quote] This is true. It can also be said that One Minute of Angle (MOA) is equal to one inch, per one-hundred yards. (the actual number is 1.047″/hundred yards)

I have a question, what about costs? how much did this treatment set you back per rifle compared to some of the other methods you mentioned ? I have heard of the taped on and sprayed on treatments and was skeptical but this sounds like a real winner. As a side note, the issue of barrel harmonics has been addressed for a very long time in the history of rifles, back in the good old days, a lot of the military rifles fully encased the barrels for just such a reason, I have an old Enfield 303 manufactured in 1919 and the barrel is tightly shrouded with wood to the end, it is solid, no vibration. That might be a manufacturer consideration to re-address, it would be interesting to buy a fully shrouded barrel deer rifle off the shelf.

Starts at $349 for carbon steel.