The wares at our local gun emporia are beginning to look a bit repetitive, my friends. There are AR15 variants for every taste, proclivity, and budget. The counters are awash to their gunwales in plastic pistols. There’s the obligatory smattering of scatterguns, precision rifles, and wheelguns, but that really is about it.

The Mk IIS Sten Gun was the world’s first sound suppressed submachine gun. Issued in small numbers to special operations forces and clandestine operatives towards the end of World War 2, the semiauto Mk IIS is a jewel in any seasoned gun collection.

If your interests wander to older iron the pickings get yet slimmer. Feel free to pick up a vintage transferable full auto Thompson if your surname is Trump, Gates, or Soros. However, for us normal folk affordable vintage WW2-era guns that will legitimately set you apart from your peers are just not available on the contemporary gun market. However, if you are handy with tools the determined gun bodger can craft some of the most extraordinary firearms legally at home. The obvious candidate is the Sten.

[one_half] [/one_half][one_half_last]

[/one_half][one_half_last] [/one_half_last]

[/one_half_last]

Sten Parentage

Sten is an acronym that stands for Shepherd, Turpin, and Enfield. Major Reginald Shepherd and Harold Turpin crafted this most basic of submachine guns at Enfield, England, in 1940. The British Army had only just barely survived the evacuation at Dunkirk, and Goering’s Luftwaffe was pounding English cities day and night. Isolated and alone, the English stood as a final bastion against the megalomaniacal aspirations of the Nazis and all their manifest darkness. While the British Army had miraculously crossed the channel intact from Dunkirk, they were bereft of weapons. In these darkest of days, Turpin and Shepherd designed a desperate gun for desperate times.

The DIY Mk IIS Sten build is fun and satisfying. The project requires a little mechanical skill and a few inexpensive tools but really is within the capabilities of most home hobbyists.

The Sten gun was known by a variety of epithets, none of them complimentary. The Stench Gun or the Plumber’s Nightmare both alluded to the weapon’s crude construction and Spartan design. However, the Sten was easy to produce in simple facilities and cost a paltry $9 apiece. This equates out to about $154 today. These same utilitarian attributes make the Sten a great build candidate for the modern ballistic hobbyist.

SPECS

- Semiauto Mk IIS Sten Gun

- Caliber 9mm Parabellum

- Barrel Length 16 in.

- Overall Length 38.3 inches

- Weight 7.75 pounds

- Magazine Capacity 32 rounds

- Action: blowback semiautomatic—closed bolt

- Sights Fixed rear peep, front post

[one_half]

The demilled Mk II Sten kit from Sarco is long in the tooth and filthy. The first order of business is to clean everything up and get acquainted with the parts.

[/one_half][one_half_last]

The Sten build kit from Indianapolis Ordnance is the only reason this project is viable. Well reasoned and professionally executed, the kit includes the unique bits you need to construct a semiauto Sten using surplus GI parts.

[/one_half_last]

Sourcing the Components—The Parts Kit

Sarco is a foundational name in American surplus. They have for decades offered the most delightful selection of gun parts, surplus military equipment, live weapons, and sundry treasure. I am convinced that Sarco is where the good gun nerds go when they die.

Sarco offers kits and parts for dozens of guns. Their demilled Sten kits are complete save the receiver and barrel. All Sten kits available these days have seen hard use, but they yet remain all but indestructible. In the United States the receiver is the serialized portion of the gun that is controlled so this component has been thoroughly slagged. There is also an inane restriction on the importation of barrels for which we have Bill Clinton to thank. The rest of the kit is greasy and filthy but entirely serviceable.

Strip the trigger housing of its internal parts. Pay attention to how everything comes out so you can reassemble it later. However, should you get turned around there is always the miracle of YouTube.

The demilled magazine housing will need some work to get apart. Grind the slagged part flat and the mag housing will slip off the back of the old receiver stub. You will need to harvest the front sight and ejector from the receiver tube remnant.

The Magical Bits

Indianapolis Ordnance is the Skunk Works of modern gun building. These guys offer a wide range of products from 80% receivers to semiauto conversion parts to legal full auto blank-firing submachine guns. Their wares include components for the MP38, MP40, MG34, BAR, and Thompson submachine guns as well as tube receiver guns like the Swedish K, Sterling, Sten, and others. I have built several guns using their parts, and their receivers and conversion parts are both well engineered and superbly executed.

Conversion parts required for the Sten build include barrels of various flavors, reduced diameter receivers, and semiauto bolts and internal parts. A reduced diameter receiver excludes the original full auto bolt and keeps the build legal. The charging handle geometry is altered slightly as well to make the gun essentially impossible to convert to full auto. Unlike the original open-bolt submachine gun, the Indianapolis Ordnance conversion uses a closed bolt mechanism with a separate spring-loaded striker activated by the gun’s original sear.

Equipment Requirements

The first order of business is to cut the usable parts away from the previous receiver remnants. This chore succumbs readily to the patient affections of a Dremel tool. Familiarize yourself with the sundry parts before you start grinding, and take care not to damage anything significant. Try to leave any attachment tabs intact on the original parts. They’re not critical, but it is easier if you have these to weld upon later. Always wear eye and ear protection if you don’t want to end the project deaf and rocking an eye patch.

[one_half]

You can harvest the old barrel bushing if need be, but it’s a pain. Indianapolis Ordnance offers a new-made replacement that is much simpler to use.

[/one_half][one_half_last]

A shop vice makes positioning the parts while you work on them must easier.

[/one_half_last]

Most of the build can be undertaken with a small drill press and a Dremel tool. A hand drill would do in a pinch, but a modest drill press is much more precise. You will need to do a little welding before you’re done, but any machine shop could knock this out for a reasonable fee. I invested in a cheap wire welder from Harbor Freight Tools that is more than capable of finishing this project. Trust me, I am self-taught and truly suck at welding and I pulled it off. You can, too.

[one_half]

Fiber-reinforced cutoff wheels will cut almost anything so long as you are patient. I burned through six during this project. Wear eye protection and a dust mask so you aren’t breathing in all that flying grit.

[/one_half][one_half_last]

The front sight and ejector come loose fairly easily after a little attention from the Dremel tool.

[/one_half_last]

Article Continues Below

Finishing the Receiver

The receiver tube from Indianapolis Ordnance comes with a paper template bonded firmly in place. Use a spring-loaded center punch to spot the necessary holes and edges of your cuts according to the template. Then use your drill press to drill out the ends of the various slots and angled bits. The ejection port, for instance, should begin as a series of four holes, one in each corner.

You could technically start the holes in your new receiver with a hand drill, but a drill press is much more precise. Spot the holes with a center punch and drill them out to define the ends of all your slots. You can dress up the edges later with a hand file.

Once the sundry holes are in place configure your Dremel tool with a fiber-reinforced cutoff wheel, don your safety glasses, and carefully cut the various slots and voids. If you had enough steel stock and fiber-reinforced cutoff wheels for a Dremel tool you could build an Abrams tank if you had adequate patience. Take your time and remove everything that is not a Sten receiver. Then swap out to a small sanding drum or grinding bit to dress up all your slots. Once the cutting is done it is time to fit our components in place.

Fitting

Carefully fit the trigger housing to the new receiver and make sure all the slots align. These things were just thrown together during World War 2 so there might be a bit of Dremel work required for a proper fit. A small hand file will reach the spots the Dremel won’t. Thankfully, the Sten gun enjoys broad tolerances and is subsequently remarkably forgiving.

You can harvest the front barrel bushing from your surplus kit, but it is a pain. Indianapolis Ordnance makes a modern replacement that is much more convenient. All the parts should slip right in place. The old ejector and front sight are cut from the Sarco kit, and they will have to be welded. Set the bolt in position and shim the ejector with a couple small pieces of paper to hold it in place while you weld it from the outside. That way when you remove the paper the bolt should slide freely with a little clearance. Once again, any proper machine shop could easily manage the required welding if need be.

Lots of tools will remove this material efficiently, but I did this project with a Dremel grinder just to prove that it could be done. Just be patient and take your time.

[one_half]

Once the front sight and ejector have been freed up smooth them out with your Dremel tool.

[/one_half][one_half_last]

Here we see the major components cleaned and ready for assembly and welding.

[/one_half_last]

Most toddlers weld better than do I. However, despite my epically crappy self-taught welding skills, I pulled this project off successfully. Grind the excess weldment down with your Dremel and fill in the voids with JB Weld automotive epoxy so it doesn’t look monkey-made.

I built my fake suppressor out of 1.5-inch muffle pipe, the stub from the original barrel shroud, and a big steel washer. Clamp everything in place and carefully weld the components together using the barrel as a mandrel to keep everything aligned. I burned through the thin steel in several places but filled in the voids with JB Weld automotive epoxy so it didn’t look bad. None of this is structural so it need not be ridiculously strong.

Keeping It Classy

In the United States, a rifle must sport a barrel at least 16 inches long to remain legal. This is a stupid rule, but it was birthed in 1934 back when telephones were wired to the wall and weighed as much as a bowling ball. Indianapolis Ordnance can hook you up with the long barrel. However, in its untamed state, the long tube just looks lame.

The answer to this conundrum is to replicate the Sten Mk IIS. The Mk IIS was the world’s first operational sound suppressed submachine gun, and it was a revolutionary piece of work indeed. The famed World War 2-era German SS commando Otto Skorzeny purportedly fired off a magazine from a captured example in downtown Berlin with passersby being none the wiser.

The wartime Mk IIS consisted of a standard Mk II gun with a bronze bolt and an integral sound suppressor. To replicate the Mk IIS in your build you simply craft a barrel shroud around the ungainly long barrel. I picked up a length of 1.5-inch muffler pipe from my local muffler shop. Cut the tube to length with a cutoff wheel on a table saw or hacksaw. The tube should extend from the barrel nut to the end of the barrel.

I bodged together an end cap out of a washer I found in my shop and carefully carved the hole out with my Dremel to accommodate the barrel. Cut the original Mk II shroud that came with your Sarco kit as a base and bevels the edges with a bench grinder or Dremel. Once the whole affair is prepped weld it together into a single assembly.

Assembly and Finishing

I took a wire wheel to the whole shebang to get rid of the rust, scale, and detritus from the assembly. Degrease everything with mineral spirits and then spray it down with bake-on ceramic engine block paint from your local auto parts store. You can bake this noxious stuff in your wife’s kitchen oven if you never want another home-cooked meal. I had an old discarded kitchen oven wired into my shop to use for this purpose. A decent toaster oven from your local box store would do as well.

The Sten gun goes together fairly readily. I sewed a canvas cover out of some heavy brown cloth to replicate the cloth heat shield of the originals. So long as you had access to these basic tools the entire project can be completed in a weekend.

If you can pull this project off you can also figure out your wife’s sewing ma-chine. An old scrap of brown canvas and some leather thong make a facsimile of the original canvas heat shield used on the wartime gun.

Range Time

Range Time

The Sten magazine is a double stack design that tapers to a single feed. This means you will either need a dedicated magazine loader or a small length of dowel to get the box loaded to capacity. Start one round at a time and take your time. You will have to tweak the sundry springs to get the gun running well, but the Indianapolis Ordnance instructions show you how.

It took me about an hour carefully trimming back the twin springs one coil at a time and then firing a round to get the gun running well. Bring your wire cutters and you can accomplish this chore from the bench at your local range just be patient. Indianapolis Ordnance provides you with two spare springs just in case.

The finished gun has been reliable with ball ammo but be careful. These components are 70+ years old. I did have one out-of-battery discharge that resulted in a squib round (a bullet stuck in the barrel) while timing the springs. There was no lasting harm done, but that is the reason we religiously respect the safety rules.

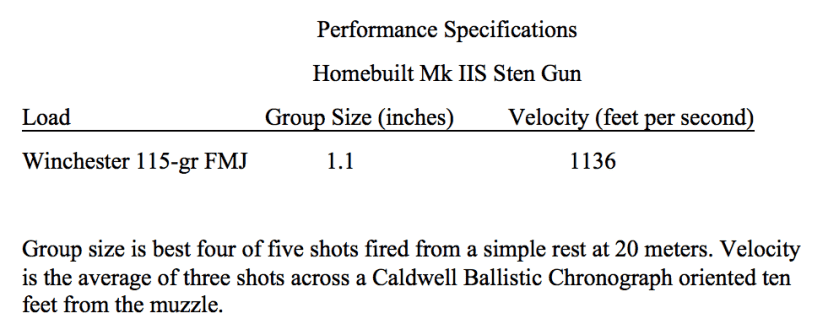

The gun is surprisingly accurate given its motley parentage. The ergonomics are hideous, but the Sten was designed to save a desperate nation, not to be comfortable. The feeling I got when I first ran a magazine through this pile of parts I built myself was remarkably satisfying.

Final Thoughts

At the end of the day, I have added something truly unique to my gun collection for less than the price of a proper plastic pistol. Don’t be intimidated by the build. I am living proof that you can be an epically crappy welder and still successfully pull it off. If the welding part still intimidates you just farm it out to your local machine shop.

This is a fairly advanced home workshop project, but it demands a lot more patience than skill. Better tools would have made the build quicker and easier, but I wanted to prove to myself and you that it could be done with a drill press, a Dremel tool, and a $150 Harbor Freight welder.

The personal satisfaction of having resurrected this old gun at home with help from Sarco and Indianapolis Ordnance is tough to measure. So long as you build the gun for personal use there is no requirement under federal law to register it anyplace or even grace it with a serial number. The Mk IIS Sten project is great fun, deeply satisfying, and thoroughly cool.

For more information about Sarco parts, click here.

To purchase parts for your build, check out Indianapolis Ordnance.

Can I have all these parts shipped to me in the UK, I’d prefer plain packaging obviously , and in amongst car part or something for obvious reasons 😉,

Why does the barrel look thicker from Indianapolis ordinance from what they show online also why does the barrel bushing look different could you send a list of everything I need to purchase to completely assemble

Great article, thank you.

So, if you want to do this, get any welding done before you cut the holes from the reciever. Until that point, none of it is a fire arm, just peices. I think it’s legal as long as the welder doesn’t bring the gun to functionality.

Those bolts and receivers cost way too much to be a reasonable build!

Nice project as for being a bad welder I burnt down our community college welding shop

We all have bad days

Nice article Doc, it is great to see a feature on this timeless classic… well done! Glad to see you on the Guns America team, I’ve enjoyed your contributions to the Firearms News in the past. Pay no attention to the “nay sayers” around here in the comment section… seems we have more than our fair share of self appointed technical and legal experts in the audience beaming in regularly from their parents basements.

Well written article and the photos were outstanding.As a WWII reenactor, I will attempt this project down the road and will save your article for guidance.

“less than the price of a proper plastic pistol”. Interesting. You apparently are getting screwed wherever you buy your pistols. I looked to go see about what it would cost me for the parts to build one i of these. To me, a good plastic pistol (Glock, xd, xdm, m&p, etc) runs between $400-$500, letting me to expect that this build would cost in the $300_$400 range. Before shipping, the barrel, receiver blank, original demilled parts kit, and internal parts kit suggested come to $657.

I can build an AK from a parts kit for about that.

Don’t get me wrong, I love the idea of the Sten and building one, but don’t say it’s cheaper that a good plastic fantastic when it’s not even close!

“prove compliance” what an upside down “constitutional republic” we live in

Horrible idea – risk a felony charge to make a piece of shit?

LMFAO!!!! ROTFL!!!!

This was the best response I have ever seen in any comment section.. EVER

Great comment Cyrus!!!!

What a bunch of candy assessment you are! The author has offered you the opportunity to resurect a peice of history and you liberal acting bastards are bitching about it! Great write up author!

Risk a felony to resist gun confiscation? In-American… *sarcasm*. Think about what you, yourself, just stated… then think about the history of America… then feel free to be ashamed of your comment. Besides, if the de-milled receiver was still considered a firearm, why would these kits even be sold to the public in the first place? You know very well the ATF would be all over this otherwise. Think before you say or write something that might end up being repeated by many more, especially when its incorrect.

Un-American**

As a dog returns to its vomit!

So does a fool return to their foolishness! Next thing cyrust will tell us is cutting the barrel of a shotgun to 18.25 inches is a federal felony.

I’m a bit of a noob but don’t you have to do all the work yourself to be legal. Having a machine shop well the receiver for you would violate that? Again I’m a noob but that’s the way that I understood parts kit building if anyone has an answer this please pipe up

The author states that you could bring difficult parts of construction to a commercial business or even a friend to have them assist completion, that would be a felony and would result in 2-10 in a federal penitentiary for both of you. Also it would be highly recommended that you photograph the kit before,during along many assembly and construction steps and after to prove compliance and save all documentation and receipts for the kit and parts. You can build your own guns as semi-auto, but doing so you still must follow existing laws.

I’ll repeat this for you as well.

That’s only true if the firearm isn’t serial numbered. Looks like the s/n is on the magazine housing, making only that the actual firearm. Everything else are just parts.

The author clearly states that the serialized part is the receiver. The receiver came as essentially an 80% part, making this an unserialed firearm, this is how DIY guns are legal. If it had a serial number it would have to be made by a Type 7 manufacturer FFL holder.

Internet experts!! Whew!!

Making/building your own firearm is legal as long as said firearm meets all the rules for a “non-NFA” firearm and the builder is not a “prohibited person”.

All work must be performed by the builder personally- not farmed out as suggested in the article.

Lastly, a serial number is not required but is strongly suggested and there are specific details about size and depth and what info should be applied if it is done. The application of a serial number is NOT what determines whether or not the firearm should have been manufactured by a class 7 licensee. If the firearm is being manufactured with the intent of reselling it for a profit the builder must be class 7 licensed.

As a class 1,2,3 and 7 licensee, I would highly recommend visiting BATFE.GOV website and order a copy of the regulations pertaining to the manufacture of firearms. It is a chore to read through, but with most violations -intentional or not- carrying s penalty if 10 year prison sentences along with a $10,000 fine it’s better to be safe than sorry.

Agreeing with Gunny1951, after I made a (non-Sten) firearm from a similar kit based on scrap for a receiver, I went ahead with required markings prior to final finish so as to be ready for paperwork transfer in the future without having to refinish later. I went to a laser-engraver place, no special paperwork since it was while-you-wait (about 1/2 hour).

Wrong, sorry. The receiver is THE FIREARM, because the BATFE says it is, regardless of the SN location, so you would be buying a 80% receiver. As such, nobody may assist you in the manufacture of it, bringing it to a commercial business would be a felony for you and the owner/machinist who did the work. You only have to add identifying marks if you intend to sell it, and you can’t make them to intend to sell them without a manufacturing FFL. ( the BATFE has rules you need to follow regarding the marks) Do that and you will never want to drop the soap in the shower..

the lower receiver is not always the “firearm”. Sig Sauer upper is the “firearm” and the lower does not have a serial number