Estimated reading time: 8 minutes

Carbon fiber barrels were once the domain of custom rifle builders, but today more mainstream rifle manufacturers are offering these barrels. Springfield Armory’s Model 2020 bolt-action series incorporates BSF Systems carbon fiber barrels. Savage Model 110 Ultralite features a Proof Research barrel. A carbon fiber barrel will add about $430 to $460 to the price of a traditional steel barrel rifle. The question is: Do you want to spend that much more?

Table of contents

Are Carbon Fiber Barrels Worth It?

The obvious benefit is less weight with a carbon fiber barrel. That’s the real wow factor with carbon fiber barrels. If you are looking for less weight, then hands down this is the way to go. From a technical standpoint, there are other wow factors to consider. Carbon barrels are as stiff as steel, and some manufacturers claim heat dispersion is better due to their carbon fiber wrapping method. A faster cooling barrel means more rounds down range without the heat compromising accuracy.

If you are one shot and done hunter, then heat is not an issue. But we all know things can go sideways on a hunt. That’s why they call it hunting and not shooting. What happens when you need to send more rounds down range and the big buck is bouncing into the next county? Will your rifle still be able to perform once the barrel heats up?

Heat And Accuracy

We all know that the stiffer the barrel the better accuracy we will get, hence the reason target rifle barrels have a large diameter and heavy contour. They look like a plumber installed a straight piece of pipe onto an action. The large diameter and heavy taper mean less vibration when the shot is fired. Thicker barrels also take longer to heat up and typically cool faster because of greater surface area. What this all boils down to is how many shots a shooter can get downrange before the heat starts to make accuracy go sideways. Accuracy degrades with shot stringing, groups can migrate to a different point of impact, and groups can open up wide and be unpredictable.

What Is A Carbon Fiber Barrel?

Carbon fiber barrels are built around a steel barrel, called a liner. The liner is wrapped in carbon fiber which reduces weight compared to steel while still exhibiting excellent rigidity and strength. This material also dissipates heat. So what you get is a barrel that can perform like a heavy target barrel at a fraction of the weight and a barrel that cools down faster so you can shoot more. Depending on the carbon fiber barrel maker, it is wrapped around the liner using different methods. Proof Research and BSF Systems have two very different philosophies on building a carbon fiber barrel. Let’s dive into that.

Proof Research vs BSF Systems

Proof Research wraps the carbon fiber around the steel liner and uses epoxy resin to bond the material to the barrel liner. The research group says they wrap carbon fibers in a helical pattern along the length of the barrel, which allows the fibers to more effectively dissipate heat from the liner. My first question with this manufacturing process is: Does the steel liner, carbon fiber layers, and epoxy all react the same under heat? If the materials don’t react the same way, they could work against each other.

BSF Systems manufactures barrels by placing a carbon fiber tube or sleeve over a stainless steel liner and loading it under tension. A proprietary nut at the muzzle locks down the carbon fiber sleeve over the liner. According to BSF, 95 percent of the carbon fiber does not touch the liner. This creates gaps and allows air to foil around the stainless steel liner so the barrel can cool faster. My first thought with this manufacturing process was: Doesn’t the air gap act as insulation? Won’t the air gap keep the barrel hot?

Shooting Carbon Fiber Barrels

I chose a Savage 110 Ultralite in 6.5 PRC as the base platform. Savages offers the rifle with a 24-inch Proof Reach carbon fiber barrel. The rifle weighs about 6 pounds naked without an optic. I’ve come to really like the 6.5 PRC cartridge and I have found the 6.5 PRC has over 250 fps more velocity pushing the same weight bullet as the 6.5 Creedmoor. I had a Savage 110 Ultralite re-barreled with a 24-inch BSF Systems carbon fiber barrel and the weight was similar to the Proof-barreled Savage.

For both rifles, I mounted the same Burris Signature HD 5-25x50mm scope. This optic has vertical crosshairs at 200, 300, and 400 yards, but you need to tweak those points of aim with your load. I found with both barrels, shooting at 200 yards with the 6.5 PRC with 140-grain bullets put my point of impact closer to 204 yards; for the 300 mark, it was more like 330 yards.

For ammo, I used Hornady Precision Hunter loaded with 143-grain ELD-X bullet. Muzzle velocity out of the Proof barrel was 2890.2 fps and 2919.0 fps with the BSF barrel. Barrels were zeroed at 100 yards and both had nearly the same round count through it.

Some Set Up

With the same action style, stock, optic, and ammo, the playing field was leveled between the two carbon fiber barrels. It was a typically hot NC summer with temperatures in the high 80s and a 3 mph wind when I fired the rifles.

I fired a total of ten rounds, one right after the other, and looked at groups during the process: 3-shots, 5-shots, and 10-shots. As I started to shoot the Proof and BSF barrels I found something interesting happening after the first three shots.

Hot Shots

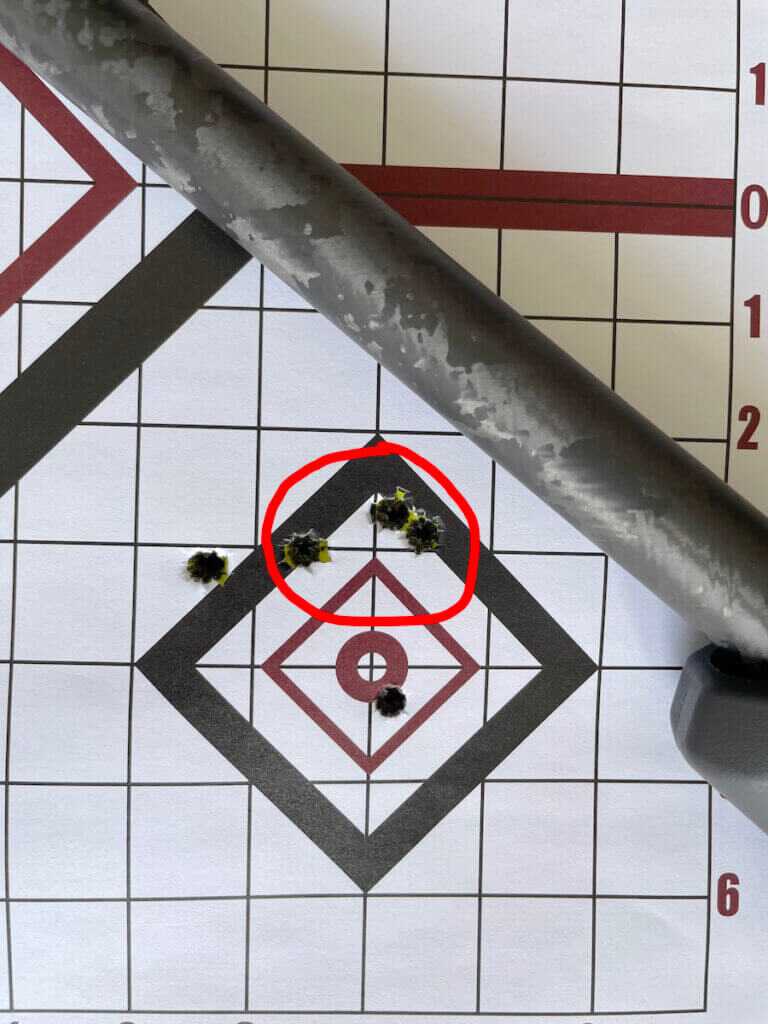

The first three shots down range were a decent 0.95 inches. The barrel was warm. The next two rounds down range started to open up with no clear grouping. By the tenth shot, things weren’t looking pretty. The group size measured 1.86 inches. The barrel was too hot to handle. With the Proof Research carbon fiber barrel, it was evident that the heat the 6.5 PRC generated caused the point of impact to significantly change.

Hot To Trot

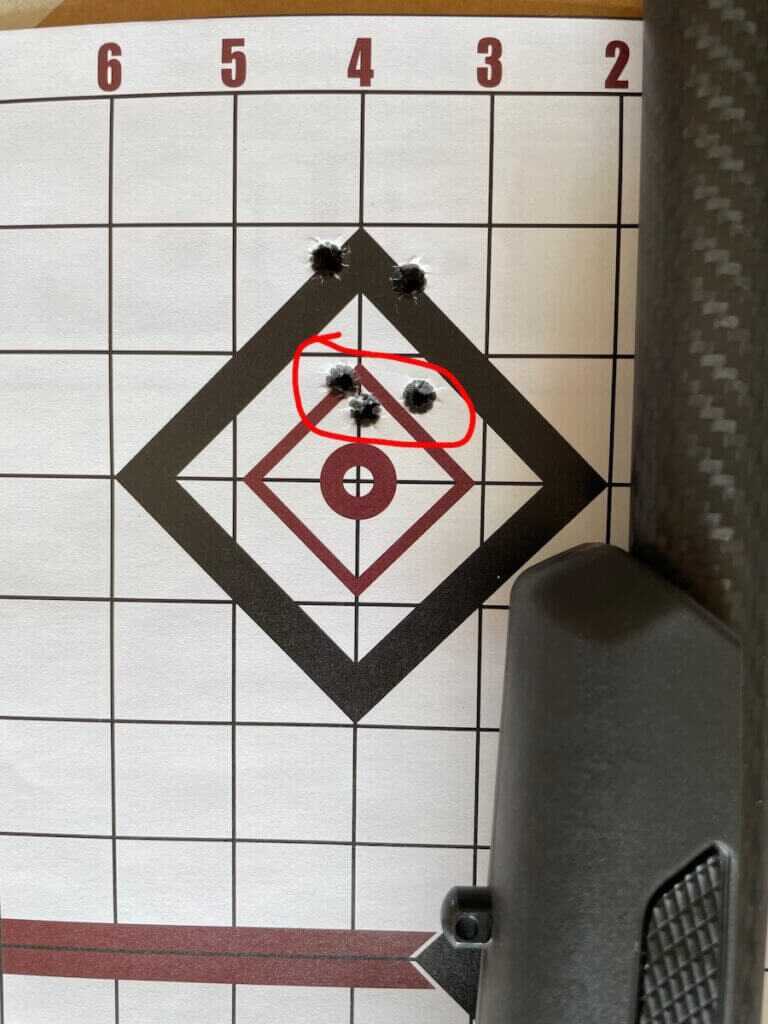

The first 3-shot group out of the BSF carbon fiber barrel measured 0.52 inches. The first group was nice and photogenic. After the fifth shot, the barrel was warm to the touch, and the point of impact changed. Shots were about one inch higher. After the tenth shot, the barrel was too hot to touch. The remaining shots all grouped an inch higher than the first three shots for a 10-shot group that measured 1.19 inches. The BSF carbon fiber barrel was less affected by the heat and though the point of aim slightly shifted it stayed put. The BSF barrel locked onto the slightly higher point of impact when heated and didn’t move any further.

READ MORE: An Illustrated Guide To Winchester Pump Action Shotguns

Which Carbon Fiber Barrel Is Best Proof or BSF?

Both the Proof Research barrel and BSF Systems barrels offer excellent to very good accuracy for the first three shots. After the barrels started to heat up, the accuracy in both barrels was affected. The Proof barrel acted a bit scattered-brained, while the BSF barrel locked into a small point of impact shift and stayed there. In my opinion, the BSF carbon fiber barrel gave much better performance than the Proof barrel.

*** Buy and Sell on GunsAmerica! ***

I own 3 BSF barrels in the AR 15 and 10 platforms. The carbon fiber sleeves are vented. Overheat has not been an issue, however I would not mag dump with the precision barrels either.