Estimated reading time: 11 minutes

We stepped inside Beretta’s living headquarters in Gardone Val Trompia to see 3,000 historic firearms, cutting-edge Industry 4.0 lines, and a subterranean range that dives two hundred meters into the mountain.

Table of contents

- Beretta’s Living History In Gardone Val Trompia

- A Museum That Rebuilds The Firearms Story

- Fine Guns Taken Seriously

- Military Cabinets And Modern Icons

- An Industrial Ecosystem With Range

- Competition Guns And The Olympic Legacy

- The Factory Floor Blends Old Skill With New Systems

- History Under The Mountain

- A Living Legacy With Family At The Helm

- Beretta Factory Tour Fast Facts

- Pros And Cons Of The Beretta Factory Experience

- Related Reads From GunsAmerica Digest

Beretta’s Living History In Gardone Val Trompia

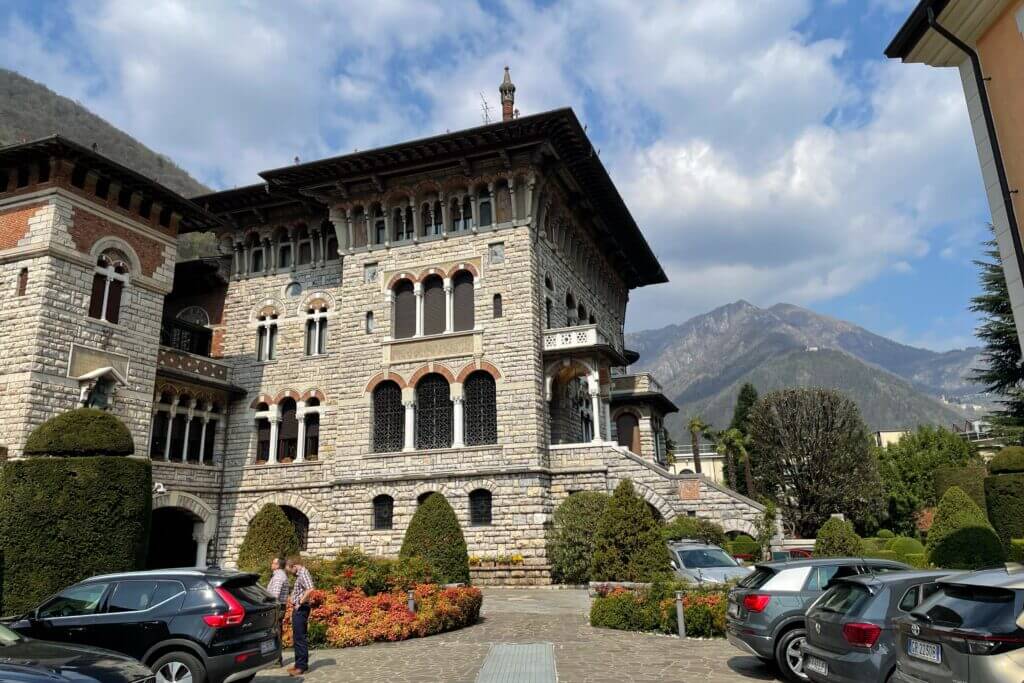

By any reasonable metric, Fabbrica d’Armi Pietro Beretta occupies rare ground in the firearms world. Founded in 1526, Beretta is the oldest continuously operating gunmaker on earth, and after touring the company’s Italian headquarters and manufacturing facilities in Gardone Val Trompia, it is clear that history here is not something preserved behind glass alone. It is something still very much alive on the factory floor.

A Museum That Rebuilds The Firearms Story

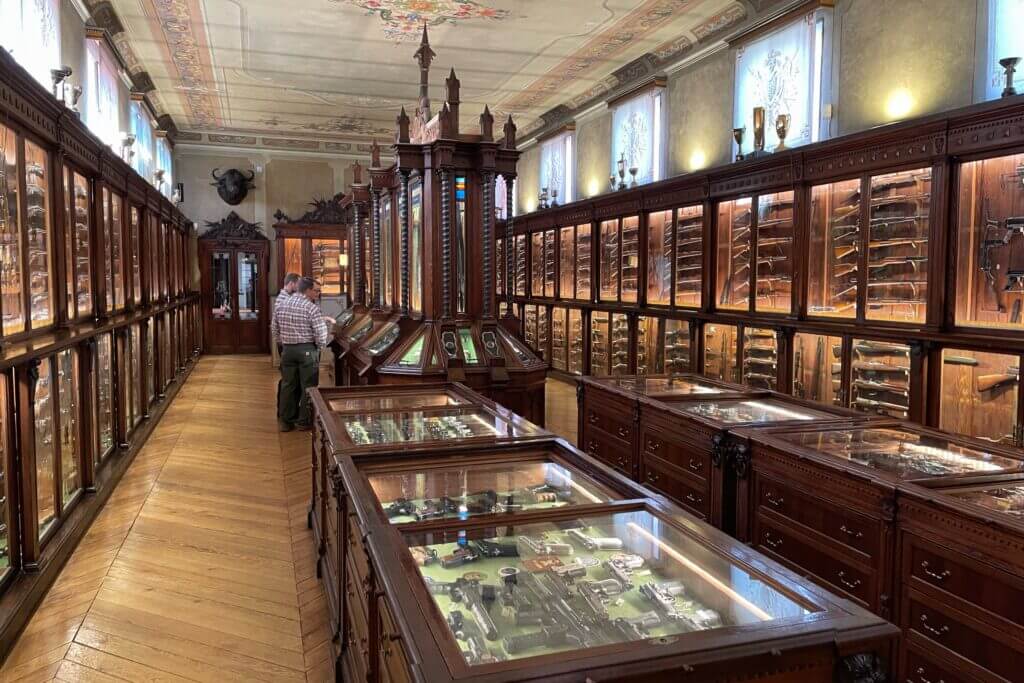

The tour begins upstairs in Beretta’s private historical collection, a room housing roughly 3,000 pieces. This is not simply a gallery of old guns. Alongside complete commercial and military firearms are prototypes, experimental designs, and examples from other manufacturers. The goal is ambitious: to reconstruct the broader history of firearms development, not just Beretta’s.

The collection is carefully divided. One side focuses on sporting and hunting arms, the other on military and service weapons. Contents of the collection range from simple, utilitarian designs to some of the most ornate firearms ever produced. Early matchlock and flintlock examples showcase black powder ignition systems, while experimental multi-barrel guns and unconventional firing systems demonstrate the significant trial and error that went into early firearm development.

One recurring theme is Beretta’s reputation for barrel making. Historically, Beretta barrels, alongside Belgian examples, were considered among the safest and most reliable in Europe. The traditional Damascus spiral method, requiring only iron, wood, water, and an immense amount of skill, relied on twisting, hammering, and forge-welding layered steel into barrels strong enough to withstand early black powder pressures. Several examples of single, double, triple, and even four-barrelled firearms illustrate the experimentation that defined the era.

Fine Guns Taken Seriously

One cabinet stands apart, showcasing what Beretta refers to as “intensified arms,” high-end firearms that exist far beyond industrial or military production. A matched pair of 12-gauge shotguns gifted to Cavalier Ugo Gussalli Beretta on his seventieth birthday exemplifies this philosophy.

Both guns are stocked from the same walnut blank, engraved by a British artist, and inlaid with five different types of gold: white, yellow, blue, green, and brown. The engraving reflects the owner’s tastes: one receiver depicts the Beretta Gallery of New York and American waterfowl scenes, while the other features portraits of his favorite dogs and a personal likeness.

Containing these shotguns is an equally remarkable gun case, built from rosewood and walnut by a craftsman connected to the British royal family. It includes hidden drawers, integrated cleaning tools, and craftsmanship that rivals the firearms it was built to house.

Not every piece in the collection is practical. One exhibition gun, adorned with diamonds, was intended to showcase the skill of Beretta engravers and jewelers. It was fired briefly until diamonds began popping out of their mounts. The gun now remains purely an object of art, insured for roughly €270,000.

Military Cabinets And Modern Icons

The collection transitions naturally into military history. Mausers, Enfields, Mosin-Nagants, and some of the first fully automatic designs line the cabinets. Among them are pistols made for foreign dignitaries, including gold-plated examples destined for Middle Eastern royalty, later redesigned when it became clear that gold’s softness and heat conductivity compromised functionality.

One cabinet houses Lugers and their accessories, while others highlight Beretta pistols that many American shooters know well, including early predecessors to the Model 92 and M9 platforms. A particularly telling example comes from a Swedish shooting school, which returned a functional Beretta pistol after 500,000 rounds.

There are also cultural touchstones, film props, Olympic competition guns, and rare markings that trace Beretta’s evolving logos. The famous three-arrow emblem, still in use today, was adopted in the mid 20th century with the blessing of Italian poet and nationalist Gabriele D’Annunzio. The symbol, originally a naval motif, represents disabling a ship’s controls, breaching the hull, and ultimately sinking it, an image D’Annunzio felt fitting for a firearms manufacturer.

An Industrial Ecosystem With Range

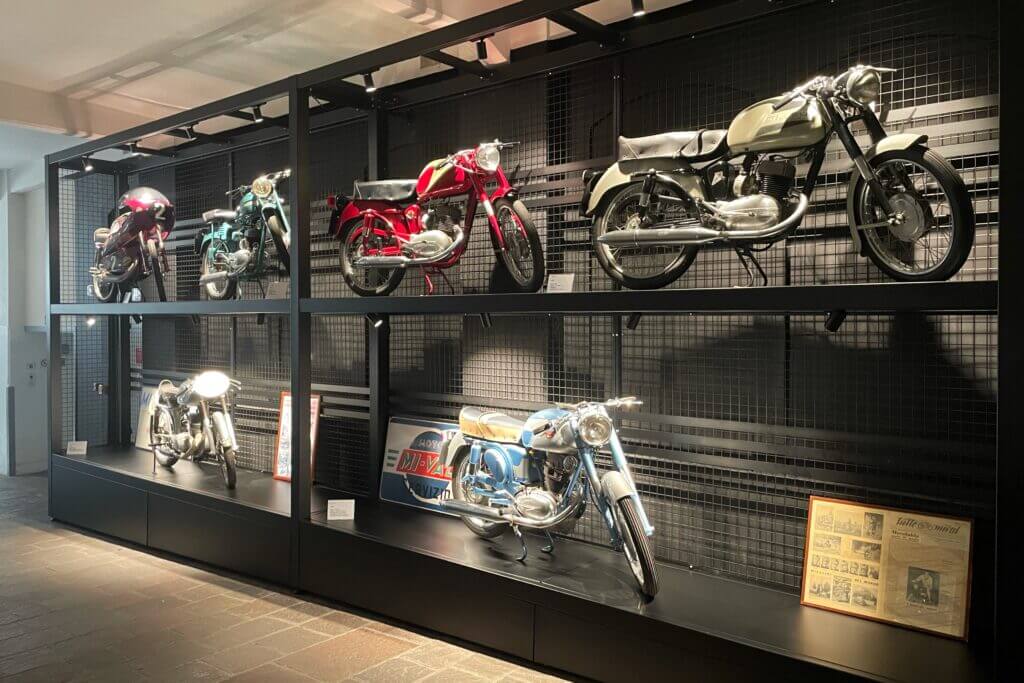

Beretta’s history is not limited to firearms. Displays include motorcycles produced in the mid 20th century, small aircraft engines, experimental watercraft, and advertising artifacts spanning decades. These ventures underscore the company’s broader engineering curiosity and willingness to innovate outside its core business.

That same mindset defines modern Beretta Holding. Today, the company operates as an integrated ecosystem encompassing firearms, optics, ammunition, and accessories. Brands like Tikka, Sako, Steiner, Norma, RWS, and others allow Beretta to offer complete end-to-end solutions, particularly attractive for military and law enforcement contracts.

The scale of the Gardone facility reflects this. The interconnected campus spans over one million square feet, with machining, assembly, warehousing, and administrative spaces linked by tunnels, bridges, and corridors. Firearms move from one stage to the next without ever leaving company property.

Tucked away in one of these corridors was an early ’90s American car, a Chevy Beretta. While Beretta did not intentionally partner with Chevy, it worked out that way in the end. Apparently, GM had brought the Beretta to market without ever consulting with Beretta Italy, which owned the naming rights. After learning of the American automobile, the Beretta family reached out to General Motors, and a deal was made for the use of the name. This deal included the delivery of one Chevy Beretta to Gardone Val Trompia, Italy, and a $150,000 donation to cancer research.

Competition Guns And The Olympic Legacy

Beretta’s dominance in competitive shooting is impossible to ignore. A wall of medals traces Olympic success back decades. From platforms like the 680 and 682 to modern icons like the DT11, Beretta competition guns have accumulated more Olympic medals than any other brand.

The development process is deliberate. Features refined with elite athletes eventually filter down into production models. Balance systems, adjustable stocks, and recoil management technologies all evolve through this feedback loop before reaching civilian shooters.

The Factory Floor Blends Old Skill With New Systems

Inside the manufacturing buildings, the contrast between tradition and technology is striking. Beretta operates an Industry 4.0 environment, with predictive maintenance systems monitoring oil levels, machine wear, and production status in real time. Screens track performance continuously, allowing issues to be addressed before they disrupt production.

At the same time, many critical steps remain firmly human. Barrel production alone involves drilling, honing, polishing, brazing, and burnishing, much of it requiring trained eyes and hands. While machines can create straight barrels, aligning and brazing over and under sets still depends on skilled workers visually checking alignment.

Beretta treats environmental and worker safety with equal seriousness. Air quality sensors monitor chromium levels, on-site medical staff conduct regular health checks, and Beretta proactively reports issues to local authorities. It is a level of self-regulation that reflects both modern standards and long-term investment in the surrounding community.

One of the most surprising features of the production floor had nothing to do with manufacturing. It was actually the sheer number of trees and plants within the facility. The idea is that if the factory is healthy for a tree, the factory is healthy for an employee.

History Under The Mountain

Perhaps the most striking moment of the tour comes as we near the mountainside. During World War II, Beretta moved key machinery into tunnels carved directly into the rock to protect operations from bombing. Workers continued production underground while the valley above was under attack.

Those tunnels still exist today, repurposed for ammunition storage and ballistic testing. The range we used plunged two hundred meters straight into the mountain. There, we fired a variety of Beretta’s new production hunting rifles and competition pistols, as well as a full-auto Beretta PMX, which recently won a contract with the Italian Military.

A Living Legacy With Family At The Helm

Today, Beretta remains a family-led company, with multiple generations actively involved in leadership and operations. The continuity is not symbolic; it is structural. Decisions made centuries ago about craftsmanship, self-sufficiency, and long-term thinking still shape how the company operates.

Walking through Beretta’s Italian headquarters is not just a factory tour. It is a reminder that while materials, machines, and markets change, the core principles behind a well-made firearm, precision, durability, and respect for the craft, remain timeless.

For shooters accustomed to seeing the Beretta logo on a slide or receiver, this visit puts everything into context. The guns we handle today are not isolated products. They are the latest chapter in a story still being written, one forged, quite literally, over five centuries.

Be sure to check out Beretta’s Website for more information on the company’s history or to browse their extensive catalog of firearms.

Beretta Factory Tour Fast Facts

| Founded | 1526 |

|---|---|

| Museum Collection | About 3000 pieces |

| Factory Size | Over one million square feet |

| Diamond Exhibition Gun | 1193 diamonds, 90 carats, insured at €270,000 |

| Swedish School Test | Beretta pistol returned functional after 500,000 rounds |

| Tunnel Range | Two hundred meters into the mountain |

| Chevy Beretta Deal | $150,000 donation to cancer research and one car delivered |

Pros And Cons Of The Beretta Factory Experience

- Pros: Deep, hands-on look at 500 years of craft; rare access to competition and military icons; Industry 4.0 insights; unforgettable tunnel range.

- Cons: Overwhelming volume of artifacts in one visit; some exhibition pieces are art only; access is limited and scheduled.

It’s too bad that NY state and the anti gun people destroyed Ithaca Gun Factory. It should have been a historical mfg building. Much of the equipment was water driven from Fall Creek. Water races were cut into the stone under the floor. Remington was chased out also as well as all the gun mfgs in the northeast.

It must have been quite a thrill of discovery to tour the museum and production floor in Italy with your professional background and mechanical interests. I look forward to reading more of your published discoveries along with Dr. Dabbs. MK