Mini red dot sights (RDS) on pistols are not a new thing. Arguably they’re one of the fastest growing trends in the pistol shooting world, but they’ve been around for quite a while. I built my first USPSA Open gun from a Glock 22 in 1995 using a slide-mounted Firepoint mini RDS. Back then, however, the quality of mounts and sights was not ideal. The Firepoint mounted to a small sliver of steel that slid into the dovetail and was held with a tiny set screw. The sight screwed down to that little mount. The lens was plastic, and it had many marks and gouges from ejecting brass. Fast forward 22 years and things come full circle.

SPECS

- Type: Semiautomatic; recoil-operated; lock breech pistol

- Cartridge: 9x19mm

- Barrel Length: 135mm

- Overall Length: 224mm

- Weight: 25.77 oz. (stock); 24.7 oz. (modified)

- Grips: Precut Skateboard tape

- Sights: Trijicon RM05 RMR (primary); CGR Clean (backup)

- Finish: Burnt Bronze Cerakote

- Capacity: 23+1 rds. with 140mm Basepad

- MSRP: $2,500 (custom); $675 (stock)

Dual Purpose

I wanted to build a pistol that would work well for USPSA Carry Optics division, but I also wanted a full-sized pistol for a shit hits the fan scenario like when Russia invades and I join Jed and the Wolverines. As with anything, when you build a gun for two purposes you have to make compromises.

I used a box stock Gen3 Glock 34 as my base. I prefer the Gen3 guns because of the guide rod system. I am not a fan of double spring systems in full-size guns even though they work well in the mini guns like the Glock 26 and Glock 43. I like to tune the spring weights on full-size guns to the load I am shooting, and you can’t do that with a double spring system. The Gen4 interchangeable backstraps don’t do much for me. I have been shooting Glocks since 1989 and I am used to the grip angle.

Carry Optics guns must be on the approved list for Production Division and I was already a fan of the G34 having used one in the Production division for years. The heart of any Carry Optics gun is the optic and its mount. I spent a fair amount of time researching optics and the various ways people mounted them to the slide.

Optic Options

The Trijicon RM05 RMR proved ideal for Carry Optics division. Note the engraved dash to help line up secondary sights.

Glock Inc. offers the G34 in a Modular Optic System (MOS) model, which has the capacity to mount various optics from the factory. For simplicity and ease of installation, it’s a solid option. Take off the slide cover; install the adapter plate for the optic; then screw the optic to the mount. The downsides are that the optic sits really high and it sits in front of the factory rear sight dovetail. Although various companies make adapter plates that fit in the factory dovetail. While they put the optic close to flush with the rear of the slide they sit even higher than an MOS gun. Both those options were a no go for me.

Many shops will machine your slide for an optic. Many put the optic in front of the rear dovetail which I hate and think is just dumb when custom machining a slide. Of the ones that remove the dovetail in machining, I didn’t think they sat low enough and/or they used tiny screws. Tiny screws break more easily and the heads and tools strip out more easily as well.

Many people advocate the optic in front of the dovetail in conjunction with very tall suppressor sights co-witnessed to the dot. This idea is sold on the premise that you have a ready to use set of backup sights, not a bad thing, and using the iron sights helps you acquire the dot in the optic. They are selling, but I am not buying.

Backup sights are a fine idea, especially with many battery-powered optics on the market having issues. However, I was convinced I could find a better solution. Using the iron sights to find your dot is just plain dumb. Learn to shoot the dot, practice until you index the gun and see the dot. A lower mounted optic will help with this as well. Co-witnessed irons are a crutch for those who don’t practice. If you want to shoot a dot, commit and shoot a dot! Don’t half ass it. The other problem with this setup is that mini RDS have tiny lenses. Co-witnessed irons take up a huge chunk of your field of view through the lens. Putting your backup irons in front of the optic (muzzle end of the gun) is less distracting but still silly for the reasons stated above.

I started my company because there were mods and parts I wanted on my personal gun that nobody could or would do. I found myself in this position again with mounting the optic to my G34.

Article Continues Below

Since this was to be a dual-purpose competition and bug-out pistol, I wanted a robust low maintenance optic. I settled on the Trijicon RM05Dual-Illuminated RMR with 9 MOA dot. A 9 MOA dot means it will roughly cover 9 inches of a target at 100 yards. As a primary or the only optic on a rifle that is too big for long shots, but this is a pistol that will only be used out to 50 yards and 95 percent of the time within 20 yards I wanted a big easy-to-see dot.

I went with the dual illuminated model since it does not use batteries. The dot is powered by fiber optics and tritium, and the dot brightness self-adjusts to ambient light. This is one of the compromises I mentioned above. In the even light, the dot is great, crisp clean and appropriately bright. The problem can show up when you and the optic are somewhere dark and the target is somewhere much brighter.

If you want an electronic sight, Trijicon makes the RMR is two other versions, a self-adjusting LED and a user adjustable LED. For a competition only gun, I would use the Adjustable LED RMR.

Cutting to the Chase

With my optic selected it was time to cut the slide for it. I looked at various ideas, mounting locations and did a lot of measuring. Once I decided on the details, the guys at Predator Tactical put the slide into the CNC mill and cut the Glock slide.

The end result is what I think is the best optic cut on the market. It sits lower in the slide. It is located at 4 points and uses the biggest mounting screws (8/32) on the market. A lower sight makes the dot easier to acquire, reduces parallax and lets you use shorter backup iron sights should you want them. The mounting screws have big, hard to strip threads and uses a big 3/32-inch hex wrench. Smaller screws use a 1/16-inch hex which strips screws or snaps easily. With the 3/32-inch you can apply more torque on the screws with less risk of breaking the tool or stripping the screw.

We still needed some sort of backup sights. I thought of running just a tritium front sight and using the base of the optic as a rear sight. During testing, it worked but was slow to line up. It needed a reference point. It hit me like a bolt of lightning. Laser engrave a vertical bar on the rear of the RMR! Now all you had to do was dot the I. I went tested it again and it worked great. The backups are reasonably fast and more importantly, there is no chunk of steel blocking half your field of view through the lens.

Accurizing the G34

The next step was to tighten up the accuracy. The only way to improve the mechanical accuracy of a Glock is with a new barrel and tightening the slide to frame fit. Things like better sights and better triggers make the gun easier to shoot accurately, but they do not change the mechanical accuracy of the gun. Many companies make Glock barrels, and the large majority of them are drop in. Spending $150 to $300 for a new barrel and not fitting it to the gun is pretty much pointless. You end up keeping some if not all of the loose tolerances of the stock pistol.

When it comes to barrels, my first choice is an oversized Match Target barrel from Bar-Sto Precision. The barrels must be fit to the gun and when done right it also has the effect of tightening the slide/frame fit when locked up. Bar-Sto uses traditional rifling unlike the Glock polygonal rifling, so they are safe for shooting lead bullets. The length of twist is a bit longer than factory, 1:16-inch for the Bar-Sto versus 1:9.84-inch from the factory. The chambers are tighter and offer more case support than stock. If you like to reload your loads long, Bar-Sto will cut the chamber for you when you order. If you do that and load short, or use common factory ammo there will be a free gap the bullet has to travel before engaging the rifling and that will affect accuracy.

The barrels need to be fit in three places. The width of the hood must be fit to the breech face. The length of the hood and chamber must be fit to the chamber cut on the slide. Most importantly, the height of the locking lug needs to be properly fit. Next time you are at a gun shop ask to see a new Glock. With the slide closed, push down on the barrel, there will be some movement and play. That is lost accuracy. With the lug fit correctly, there will be no play and that taller lug pushes the slide up, so the frame rails ride on the bottom of the slide rails. It is not a true tightening of the slide/frame fit but it has a similar effect.

For those not wanting to have a barrel fit to their gun, Bar-Sto also offers their barrels in a semi-fit spec that will drop into most guns, but much tighter than factory barrels.

Trigger Time & Serrations

In a normal competition Glock, I would set up the trigger at about 2 pounds. Since this is dual purpose I wanted something a little heavier. The pistol is a Gen3 but it comes with the latest Gen4 triggerbar. I swapped that for a Gen3 version as they break a little cleaner. I also swapped the stock 5-pound connector for a factory 3½-pound connector. All the trigger parts were deburred and fit, and then finally polished to a mirror finish. Using all factory parts the trigger was breaking at 3 pounds, 9.6 ounces. The reset was a little heavy, so I changed to a lighter firing pin spring which brought it down to 3 pounds on the nose.

I removed the finger grooves first. I have big hands and they don’t line up for me. I accomplished this with a belt sander. One slip and you just bricked a new frame. High gripping was next to take the hump off the trigger guard. It eliminates Glock Finger, which is the blister shooters get on their second finger knuckle. This also lets you get a higher grip on the pistol for more control.

Lastly, I relieved the frame around mag release. It makes the mag release easier to hit, especially if you have big thumbs. You could also go with a bigger extended mag button but it is easier to hit at the wrong time or to catch on clothing and such so I prefer a stock release with relief for carrying. Thankfully for companies like Predator Tactical helped add front slide serrations. I also wanted front slide serrations. The guys came up with the serrations you see on the finished gun.

After the slide was machined and barrel fit a lot of the metal was bare. Justin Ellis Cerakoted both the slide in Burnt Bronze and the barrel Black. The Bar-Sto barrel is stainless and did not need Cerakote, but the gun looks a lot cooler with the barrel black.

The last step was to change the guide rod and recoil spring. At the dawn of USPSA Production, I designed a full-length tungsten guide rod for the Glock 34 and 35 with THE Accessories. The rod extends into the hollow channel and is flush with the front of the slide. The rods have been out of production for a number of years but now Glockstore is making them and sent me one for the build. The rod weighs in at a little under 2 ounces and puts that extra weight right where you want it to tame recoil – up front and down low. I am a big fan of tungsten guide rods and use them in both my carry and competition Glocks. It’s not a night and day difference but it does help and it’s well worth the $40 to $60.

Another advantage of an aftermarket guide rod is that you can tune the gun with recoil springs. I prefer the factory style flat wound recoil springs from Integrated Systems Management, Inc. (ISMI). With a 9mm gun, I typically start with an 11- or 13-pound spring and then experiment. The 13-pound was a little heavy and led to a couple of jams while shooting a match. After more testing, the 11-pound spring proved ideal.

Most factory guns are oversprung out of the box. The heavier the spring, the more work the shooter has to do to counter that spring. The lighter spring also transfers the recoil to the shooter over a shorter duration which makes it feel like it is recoiling less. If you are worried that a light spring will lead to frame battering on your Glock — don’t. The plastic in front of the front frame rails will get slightly misshapen and then stop. I have a few Glocks in various calibers with 50,000 plus rounds through them, and it is simply not an issue.

Range Time

With the gun finished it was time to shoot it! Hornady was kind enough to provide me with test ammo in a variety of flavors: Critical Duty 135-grain +P, Critical Duty 115-grain FTX, American Gunner 115-grain XTP and 9mm Luger 124-grain XTP.

Additionally, I tested three handloads I use in Glock Sports Shooting Foundation (GSSF). GSSF scoring values accuracy over time, so these loads were made to be accurate first and shoot soft second, but they still shoot pretty softly. All three loads use the same charge of Vihtavuori N320 powder and the same overall length, primer, and new Starline brass. From Hornady, I used the 115-grain and 125-grain Hornady Action Pistol (HAP) bullets. HAP bullets are based on the XTP bullet but without the cannelure and folds that help with expansion. Like the XTP they are a hollowpoint. The 115-grain HAP is a standard 9mm bullet with a .355 diameter. The 125-grain is .356 in diameter. Both work in 9mm firearms, and I wanted to see which size this pistol preferred. I also used a Montana Gold 124-grain JHP, which has a similar truncated cone shape to the HAP, XTP and FTX bullets.

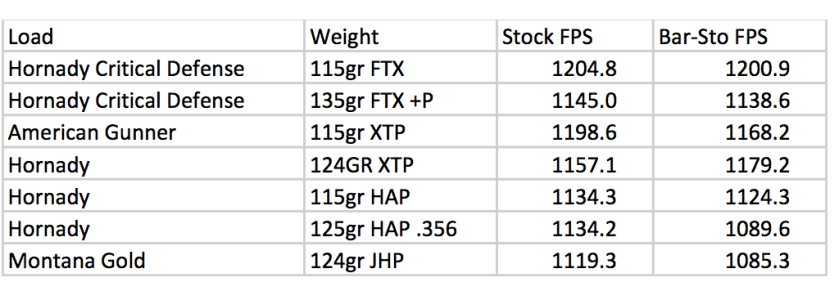

I fired all rounds through my Pact chronograph with both the factory and Bar-Sto barrel.

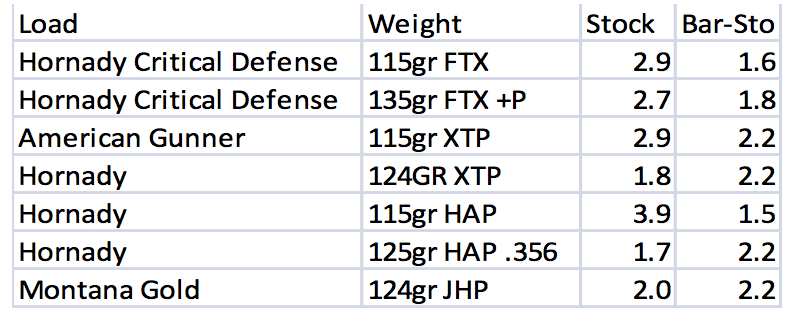

I also shot all seven loads for accuracy with both barrels. I fired a six-round group (I typically have one self-induced flyer these days) with each load at 25 yards using my range bag as a rest for my arms. I measured the best 5 shots edge to edge then subtracted .355 (the bullet diameter) to get the group sizes below.

The Bar-Sto shrunk group sizes significantly in most cases. The 115-grain HAP was the overall champ of the day.

The last test for this gun was a match. Plenty of people compares Carry Optics type guns to iron sighted guns. I have also seen some people claim their Carry Optics gun was “basically an Open gun”. It is not. I wanted to do something different and put the CO gun head to head against my Open Steel gun in a match with the same ammo. The Open gun is based off a Glock 17 and is a proper Open gun with a frame mounted optic and a compensator.

I shot the entire match with the Open pistol first then the CO pistol, which gave the CO gun a slight advantage. The first thing you notice shooting them side by side is that it is much easier to track the dot through recoil with a frame mounted optic. Before dropping the spring weight on the CO tracking the dot was much harder. You also notice that the Open gun has less muzzle flip, due to the comp. On the stages where I shot clean with both guns, the times were close but as expected the Open gun prevailed. Longer stages led to a bigger margin of victory for the Open gun. See the video for some footage of both guns on the same stages.

Overall, I am very pleased with how this new build turned out. Both how it shoots and how it looks. For the time being, I will continue to shoot it here and there in matches.

For more information about Hornady ammunition, click https://www.hornady.com.

For more information about Bar-Sto Precision, click https://www.barsto.com.

For more information about Trijicon optics, click https://www.trijicon.com/na_en/index.php.

For more information about ISMI, click https://www.ismi-gunsprings.com.

To purchase a Glock 34 on GunsAmerica, click https://www.gunsamerica.com/Search.aspx?Keyword=Glock%2034.

The title is a complete misnomer! Apparently there are no worthwhile guns unless they cost over $2400.00 to use when/if sh@t hits the fan.

I will use whatever is at hand, but I myself prefer something larger than 9mm. But wait every time someone asks me anything about shooting they all boo hoo about recoil, whether it is a pistol, rifle or shotgun. All I ever here about using a pistol is them wanting a 380. They all want the recoil of a squirt gun.

I attribute it to the pussyfication of America. Now do not get me wrong, recoil can be an issue with some guns and for those who shoot a hell of a lot, but in many cases recoil can be abated some in many instances.

P.S. Lone Wolfe same thing just better & cheaper

30 round FN 5.7 with a Jarvis threaded barrel & Silencerco Sparrow

A GLOCK?!?!?!

NEVER!!!!!

The 1911 is now and always will be the best!

When you run out of ammo, it makes a good club!

Had two Glocks. Both Gone. Still have my 1911’s. Different makers of the same frame,still going strong with out failure.That says it all for me. The Glock seems to be the one that gets a lot of attention by writers. ?

Gets a lot of attention also from competitors, and law enforcement, and people who want safe, accurate and not overly complex firearms. There’s a reason why almost everybody and their brother has tried to knock off the glock. You do get some extra man points for the 1911 though.

Why not just get a Sig P320 RX with an assortment of magazines including some 20 rounders. Save a ton of money And not try spend all that unnecessary money to make a glock into a Sig p320 rx

Good call being 3 rounds down from everyone else in Production. That certainly wont make a difference on a stage.

Good writeup. Thanks!

Not knowing when the “S” would “HTF,” I guess I’d have to rely on my EDC gear. Hopefully, that would be sufficient to get me to my vehicle (which could hopefully get me to where I need to go). I’m just not going to pack a G34 every day. I might have that in my vehicle, but there’s no guarantee I’d be able to get to my vehicle.

I guess the problem with “dual purpose” firearms is that they end up not doing either task as well as a dedicated firearm for a single purpose. The author proved that rather expensive point. What would have made more sense though (to me) would have been to fit a threaded barrel. That way, a compensator or a can could be used if required. It would have been interesting to see how this build with a compensator would have done compared to the author’s compensated G17.

The nice thing about a Glock is that, to me, it’s a tool. In it’s stock form, I could care less what happens to the thing, (gets beat up/taken into evidence/kicked across the pavement…). Also, with the looser tolerances, Glocks tend to function better in less than optimal environments and still maintain decent accuracy. Chuck Taylor explored that, along with super high round counts, many moons ago.

$2,500 could buy some nice equipment, ammo, even a nice handgun or rifle that might be more effective under SHTF scenarios! It could even buy an amazing case of Scotch to make unpleasant events more tolerable.

The author did some great work on that gun. For me, customizing a Glock just doesn’t make sense unless I’d want to use it for competition. Even then, I might just use a stock (EDC) gun to improve my skills for when, as the one and only Louis Awerbuck used to say, “The fecal matter hits the oscillating device.” RIP Louis!

So you take a $675 pistol, then spend triple that cost on customizing it (including the red dot sight) . Even though you sate: “but this is a pistol that will only be used out to 50 yards and 95 percent of the time within 20 yards”.

So now you have a $2,500 rig to shoot 95% of the time at 20y. Okay. I suppose this rationale is why some will spend $15k on mods to their 1998 Honda Civic, just so they can hit 45 mph between stoplights on each block in Los Angeles traffic.

Yes, if you throw a Glock, ANY Glock, into a fan, that would ultimately be sh!t hitting the fan. I wouldn’t have a Glock as a gift.

Now that’s some funny stuff. Got a Glock 23 for carry but it’s not my favorite gun. My 8 shot S&W 357 is the best gun in my safe. Don’t carry it because of size but that’s the one I’ll grab if I can. Block is “OK” but over rated.

Nice write-up, but IMO there is no one “ultimate” SHTF handgun. That depends on what kind of fertilizer is most likely to hit the oscillator in your case. Yep this Glock looks like a good choice of sidearm for an outed CI who refused to enter a witness protection program. But it’s still a 9mm. Maybe with those fancy sights you can hit an angry bear in the eyeball.

I’m not a Glock person, but this build would certainly do it’s part getting you through a SHTF scenario, no arguments there.

Nice write up, I appreciate all the detail given.