Is it possible that two brothers from Arkansas – men with a passion for shooting but who are not firearms engineers or designers – have invented a device that can actually improve our pistol shooting noticeably and reliably, for under $40 and featuring a very easy installation?

Available on GunsAmerica Now

After shooting a number of pistols with and without the device, called the Stacker and sold at Stacker Tactical, this writer’s answer is, “Yes, they have.”

The Stacker is the brainchild of brothers Jim and Michael Rofkahr. Jim, 61 and a consultant for the rendering industry, and Michael, 52, a facilities manager for electric utility, started work on what would later become the Stacker a couple years ago after Michael purchased a new pistol, then had a custom trigger job done. But even with the custom work, Michael felt there was still something throwing off his shots.

After taking apart said pistol and examining the workings of the trigger assembly, the brothers ran the handgun through various tests. They concluded that the larger problem was not the trigger’s break per se. The pistol’s accuracy was being affected, they decided, by the energy created inside the pistol once the sear was released and the striker-firing mechanism was activated, plus the slight jarring that occurred when the trigger came to a full stop.

All of this energy, the brothers realized, was transferred to the inside of the pistol’s frame, and they concluded that this energy pulse helped to destabilize the pistol.

“Shooters have always intuitively known that lightening the trigger pull would make a gun shoot more accurately because it imparts less instability during the firing process,” Michael told me. “They didn’t know the physics or math behind it, because it seemed to be common sense. But, when you look at the math for kinetic energy you find that managing [or lightening] the trigger pull force has only one-quarter the influence as managing the [sear] velocity at release.”

He added, “It’s rather surprising to find that managing or absorbing the velocity after sear release is four times more effective [in reducing instability] than lightening the trigger pull. And, the safety margin for sear release stays intact.”

And how did the brothers measure this internal energy release?

According to Michael, “We developed a test jig that holds the pistol in a manner which simulates the grip of an average shooter. We then mounted vibration probes in the X, Y, and Z axis relative to the barrel discharge. We then captured the movement signature of the barrel, with a digital storage oscilloscope, at the moment of sear release to observe and measure the degree of displacement when the trigger release kinetic energy was transferred to the frame.”

He continued, “What we observed was about a 4X reduction in average displacement for some weapons. Heavier weapons were not as pronounced, while modern, light-weight polymer framed weapons were the most impacted by the phenomena.”

The Rofkahrs then focused their efforts on the SIG P320 9mm platform, a popular choice among law enforcement and built with an easy-to-access, modular trigger assembly which Sig terms a “fire control unit.”

The question became: how to lessen the impact of the energy released inside the pistol on the sear’s release, vibrations that pulsed through the pistol just before and during the ignition of the round and potentially affecting accuracy? Something was needed to absorb that energy, they decided, within the trigger assembly itself.

“Absorbing devices must be manufactured with tight tolerance so as to engage the trigger mechanism right at sear release, but not too soon as to add too much additional trigger pull force,” Michael explained. “And the absorbing material we use is a unique elastomer which is efficient at non-reflective energy transfer. That is to say, it’s not as simple as it appears.”

Jim added, “In redneck terms, The Stacker is a shock absorber of sorts.”

For the Sig P320, that shock absorber they designed, the Stacker, is an “L”-shaped piece of elastomer, an elastic polymer, which fits inside the slot just ahead of the trigger bar. The Stacker greatly reduces the energy which would otherwise vibrate through the internal workings of the fire control unit once the sear is released and the striker-firing mechanism is activated.

I was initially contacted by Jim Rofkahr via my LinkedIn page. His first message informed me that he and his brother had developed inventions to improve pistol accuracy, and they had been granted two U.S. Patents. The patents caught my attention:

— “L shaped trigger dampening absorber,” a patent granted by the United States Patent and Trademark Office (USPTO) as US-D865900-S;

— “Elliptical trigger dampening absorber,” a patent granted by USTPO as US-D918330-S.

The “L shaped trigger dampening absorber” is the Stacker; the other patent is for a device that fits in behind the trigger itself to absorb trigger-stop energy.

After many emails and phone calls, Jim traveled to my home range in Wisconsin with the Stacker, several pistols, and other versions of these pistol “shock absorbers” including the “Elliptical trigger dampening absorber.”

First, some disclaimers:

I had no way to mechanically measure the kinetic energy produced inside the pistol or absorbed by the Stacker. But as a writer/shooter, it seemed to me that if the Stacker actually worked, one way this would be apparent was in rapid shooting sequences where patterns usually widen. Some of that widening, of course, is due to muzzle flip and general recoil.

However, if these energy pulses inside the pistol were adding to the instability, pulses which were then absorbed in Stacker-outfitted pistols, I thought Stacker-equipped pistols should print tighter overall groups compared to stock pistols.

I am not a mechanical engineer or a physicist. Yet, people like me (and my readers) are the “end users.” We may not understand all of the physics and other mechanical operations going on inside the pistol, but experienced shooters know when one pistol works better than another simply by the ease of shooting between various models, and by comparing the accuracy and overall function.

Think of it this way. If you are in the market for a new car and drive several models, you don’t have to be an automotive engineer to know which models accelerate faster, and which ones take turns smoother or hold the road better.

Such was my operating theory when testing out the Stacker.

Jim Rofkahr and I met at my north-central Wisconsin shooting range on the morning of November 3, 2022. The handgun lanes at my range are outside; the morning was sunny with little to no wind and the temperature was in the mid-50s.

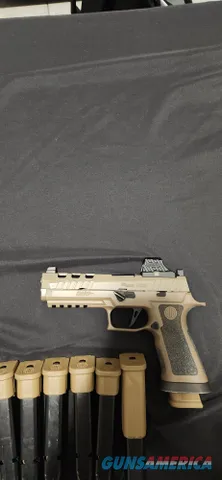

Jim had brought two different Sig P320s: his personal Sig P320 Compact; and, a Sig P320-M17 he’d borrowed for this testing.

Jim showed me the Stacker, and then removed the slide from his P320’s frame and demonstrated how the Stacker fit into the small slot just ahead of the trigger bar.

Using range ammunition, I ran a 10-round magazine through the non-Stacker equipped P320-M17 using a target set up five yards away. It performed fine. So, I set up a human silhouette target and at ten yards and shot off ten rounds fast into the target, offhand. I did this twice.

Then, I used Jim’s Stacker-equipped P320 Compact and followed the same procedure, firing it first to see how it felt (good—with a definite easier trigger function) and then did two ten-round magazine dumps at ten yards.

At the five yards, and taking time to aim, groups from the Stacker-equipped Compact and non-Stacker-equipped M17 were pretty close to each other in size, with the edge going to the Stacker-fired groups.

It was at ten yards and firing ten rounds fast that I experienced a definite improvement in my groups with the Stacker-equipped P320 Compact pistol. To make sure the differences were for real, I then shot the P320-M17 with and without the Stacker three separate times.

In all my rapid shooting sequences, the Stacker-added P320-M17 put my shots into a 4.0- to 4.5-inch grouping, while the non-Stacker P320-M17 shots placed at approximately 8.0-inches.

Three times with and without the Stacker and my groups kept printing the same way: noticeably larger groups without the Stacker, with groups half the size with this little elastomer shock absorber installed.

Next, I tried out a Sig P365 9MM with the Rofkahr’s “Elliptical trigger dampening absorber” secured behind the pistol’s trigger. This elastomer foam device definitely smoothed out trigger pull, engaging the rear of the trigger when it was pulled back about halfway, and it did seem to absorb what would otherwise be the snap of the trigger against the rear of the trigger guard.

With the foam insert behind the trigger, my five-yard groups, fired offhand and steadily, printed .50- to 1.0-inches tighter than the stock P365.

In my non-engineer opinion, the Stacker and the related behind-the-trigger device did make my shooting more accurate, especially when emptying out magazines fast.

Some caveats…

First, if you are already a very good pistol shot, I don’t think the Stacker will noticeably improve your shooting accuracy when firing slow and steady, especially at distances of five yards and under. The Stacker may make your shot a bit more accurate but, pragmatically speaking, hitting center mass or hitting .50- to 1.0- inches away from center mass seems to me a toss-up.

There are also warranty issues to be considered. Most new firearm warranties clearly state that altering the workings of the firearm will void any warranty coverage. So, install the Stacker and your new pistol’s warranty will be voided, I’d assume.

All in all, though, yes, the Stacker internal device as well as the behind-the-trigger device made my admittedly limited shooting more accurate.

The Rofkahr brothers hope a firearms manufacturer will see the functionality of the Stacker and related systems and purchase the rights to the patents.

In the meantime, the Stacker internal device for the Sig P320 is listed for $39.00 at the Rofkahr’s Stacker Tactical website. Eventually, the behind-the-trigger device and Stacker internals for other pistol models will also be offered for purchase. The website also features a video showing how to install the Stacker.

*** Buy and Sell on GunsAmerica! ***

I have not been satisfied with the accuracy of my full size P320 and purchased a Stacker after reading this article.

I fired a 10 shot group with my stock P320 with RDS at 25 yards from a bench with a pistol rest and got a 4.5 inch group.

I installed the Stacker and repeated the test. I got a 3.25 inch group with the Stacker. If I take out one flyer (that was my fault) the group was 2.25 inches.

I then fired about 100 rounds and experienced no issues and the Stacker. I am going to continue testing to make sure the Stacker does not affect reliability. Very satisfied so far. I was ready to call it quits with the P320 and this small item may have saved the gun for me.

I don’t think these devices will affect warranties since they do not involve physically altering any parts. They only add parts that are completely removable.

That said, this is a very interesting development. I hope they continue their research and eventually add more firearms to their list. Devices for S&W M&P and Glock would likely be in demand.

At any rate, I wish them well with their new products!

And, God forbid, you shoot someone in self-defense and the prosecution finds out you altered the gun inside, he’ll have a field-day sending your ass to jail.

I know these men personally, they are the real thing. I can tell you that Mike is as smart and as detail oriented as ANY engineer on the planet. I helped them with some prototyping for this product for another make of gun. This concept can help any striker fired pistol to shoot more consistently and accurately. They have been working on this for a long time, this is NOT “Snake oil”, it works.

No blind test was conducted. That would have given a more accurate test. the author shooting for speed and not knowing which pistol he was shooting. Just sayin’