This is not my revolver, it belongs to the GunsAmerica editor. I do have a good amount of trigger time on this Smith though, before the finishing and after. We spoke to WMD at NASGW last October about them doing some coating on an AR project we were (and still are) working on. During the conversation they mentioned the coatings they do on stainless guns. Our interest was peaked and we arranged for them to work their magic on David’s Smith and Wesson 686. WMD was given carte blanche to do whatever finish they wanted.

[full_width]

[/full_width]

Looking for a solid 686? Buy one on GunsAmerica: /686

The 686

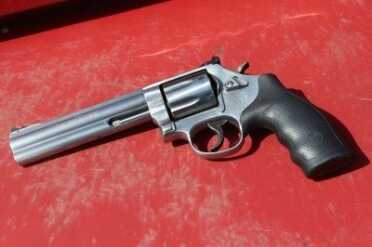

The Smith and Wesson 686 that WMD finished is actually one of the plus models that holds 7 rounds. For some more details on the 686 check out David’s full review.

Like I said above, I know this gun fairly well. David’s 686 is a great shooting .357. This is also a stock revolver. It has not had an action job done to it. The single action pull is light and short and as good, or even a bit better, than most stock single action revolvers. The double action pull, although not as nice as some I have shot, is good and very reliable. The 686 locks up tight and is timed correctly.

In short, this 686 is exactly what a 686 should be and functions like a well make Smith and Wesson. So why mess with that? Because we can!

Finish on a Stainless Gun?

I know what you are thinking. You have been probably thinking it since you started reading this article and I wouldn’t be to surprised if at least a couple “readers” didn’t jump straight to the comment section and call us some colorful version of an idiot for putting a finish on a stainless steel gun. Yep, it takes all kinds. Us included.

So why would we or you want to do something like this? Well, contrary to what a lot of people think stainless does not mean rust-free. Stainless steel will, can, and does rust. Now it is not as prone to corrosion as other steels, but it will happen. Coating a stainless gun might be the equivalent of putting on two condoms, but sometimes its better to be have a little extra protection.

We also talked to WMD about developing a modern “Combat Magnum.” Now the original Smith Combat Magnum was a Model 66 and not a 686+. This not a 66 vs 686 article and we didn’t have the later to send to WMD anyways. But the general idea was to add a protective coating to the revolver, not unlike what people are doing to 1911s and other pistols, to make it more resistant to the elements and theoretically more reliable. We wanted to take an already rock-solid gun and make it as indestructible as possible.

WMD (not located in Iraq)

WMD offers a lot of different finishes. They are best know for their Nickle Boron work. They coat a lot of parts for a lot of different manufacturers. If you have an AR with a coated bolt, there is a good chance WMD is the one that did the coating.

WMD used their NIB-X Nickel Boron process on most of this 686. If it isn’t black, then it is Nickel Boron. So what the heck is this dark magic wizardry? This is what WMD has to say about it:

NiB-X is our proprietary formulation…and a remarkable technology that proves that not all nickel boron coatings are created equal. WMD was a pioneer in the use of nickel boron technology in the firearms industry, and not only is our coating formula unique; our application process is, as well. We’re confident that our NiB-X coating provides the optimal combination of hardness, wear resistance, lubricity, and corrosion resistance. The coating has a Rc 70 and a coefficient of friction of .06. NiB-X maintains its properties in high temperature applications and is impervious to most chemicals (Nitric Acid notwithstanding). It has the same material properties throughout the structure of the coating so integrity and properties are maintained throughout the thickness. Coating can be duplexed with sublayers or topcoats to enhance specific properties customers may desire.

Basically it is a protective coating that is slick, which is why it is a fantastic coating for an AR bolt. It does add a measurable layer to the parts–between .3 and .5 mm. The finish, if you look at ti under a microscope, would like like tall bumps. This is how it cuts down on friction–only the tops of the bumps come in contact with anything, reducing the contact surface area.

That is why the cylinder on this 686 is black. If they would have coated the cylinder with the NiB-X then it would have tightened the chambers and the throats.

The parts that are black were coated using Nitromet Salt Bath Nitrocarburizing process. This coating does not change the dimensions of the parts. Here is how WMD describes this process:

This process is the new industry leader in bore coatings for firearm barrels—achieving a 30% greater lifespan in the bore than chrome! It provides a Rc 55 surface through a high temperature diffusion process. This technology is applicable to metals that can withstand the processing temperatures such as barrels, gas blocks, magazines, steel receivers, revolver cylinders etc.

The black finish doesn’t change the dimensionality of the chamber in a way that alters its performance. So cylinders, hammers, triggers, other small parts… they all function as they should. If the same moving parts were coated in the NiB-X, you would have to ensure that everything still fit precisely.

This led to an interesting conversation with Lee Grier, one of wizards performing this magic at WMD. We had sent the 686 because we assumed the revolver would be more of a challenge then a pistol. Pistols, most of them anyhow, have lose tolerances. Not so, says Grier. There are more nuances to autos, as each locks up a bit differently. Even within specific models, Grier noted, there can be slight variations that make coating with NiB-X a challange. “You learn what [the gun] is supposed to feel like,” Grier said. “A lot of the work has to be done by hand.”

Shooting

When the 686 came back from WMD we of course had to make sure it still shot as well as it did before. It does. The trigger feels the same, and weighs-in, and the cocking of the hammer is still smooth. I put a couple hundred rounds through the coated 686 and the finish shows no wear or issues.

We did notice that the cylinder pin was hanging up a little when opening the cylinder. It was not hanging up enough to cause a failure, but it did take a little more force to open then before. We called WMD and they said that is a normal by product from the thickness of the coating and that it will polish in with continued opening and closing of the cylinder. After the 2nd range trip, I can say that it is getting better but not as smooth as it was before the coating. The pin riding on the NiB-X won’t cut through the coating, but it will smooth out the surface.

Just to be clear here. This part doesn’t move like it did before the coating. No big deal. It opens and closes easily, even with the slight drag. It should get better over time. And it seems worth it for the extra protection provided by the NiB-X.

Thoughts

In my opinion the 686 came out looking a little… ugly. I am not a fan of two-toned guns. But we didn’t send this revolver to WMD and tell them to make it look pretty. But these are not color choices that they made, these are the only colors of the finishes. The champagne silvery grey is the color of NiB-X and the black is what the Salt Bath Nitrocarburizing (say that 7 times fast) looks like. They were told to work their magic to make “combat revolver” that has the best functional and protective coating available. That is exactly what they did.

If they were told to make it pretty, they could have polished the NiB-X (which will come out looking like hard chrome), or they could have added a Cerakote finish to the top of the Nib-X to change the color.

So how much does the process cost? It varies based on how much of the gun you want coated. For a revolver like this, we’re talking somewhere around $200. There are price-lists on the WMD site that can give you a good idea.

It is worth the expense? I think so. If your gun is a serious tool, it is defiantly worth it. I’m thinking here of those delicate blued finishes on so many of the guns I own and how you have to baby them. There’s no babying this 686 anymore.

[one_half]

[/one_half][one_half_last]

[/one_half_last][full_width]

[/full_width]

[full_width]

[/full_width][full_width]

[/full_width]

I’ll stick with Armoloy .. no buildup to hinder function and you can’t cut it with a file. I had a blued 3″ Mod 36 Chief coated with this in 1978 and it has survived years of salt water with no problem.

Hmmm…Let me be the first to say you need a bit of a S&W history lesson. The original Combat Magnum was a K frame, 357 Magnum marked 19-3 in the yoke of the frame in front of the cylinder. “Combat Magnum” was stamped on the right side of the half-underluged barrel, and they arrived on dealer shelves in a high polish blue or nickel. I might err here, but I believe that was 1954, and they were discontinued in 1999. …J J

Yep, and the Model 66 I talked about is the stainless version of the “Combat Magnum” Model 19. Since we were talking about stainless guns I mentioned the 66. The 19 first shipped in 1957 and were marked 19 in the yoke. The 19-3 you mention wasn’t made until the mid 60’s. The number after the hyphen on S&W revolvers indicates an update or slight design change. For example, when they went from 3 to 2 screws on the frames.

Stopped reading midway through, after total grammar-fail overload. HIRE A FUCKING EDITOR, please. Very sloppy.

Sound more like a swabby than a jar head. But then again foul language is a sign of low intelligence.

Or sometimes it’s just a sign of someone who’s patience has been over-taxed & is at an end. I know how the gunny feels: I didn’t even get beyond the 1st paragraph when the author misspelled “piqued.” [NB: don’t use cliches in print if you can’t spell them properly! ::) ]

BTW, I own 2 Taurids, a 940 in 22lr [which had an execrable double-action trigger as new; I think I measured it once ~ 18lbs? Unfortunately the fix of reducing the trigger return spring has left it prone to reset failures; I may replace the Wolff spring with the original and just consign myself to using it as a quick-loading single action] and a 357 [I forget the model#] which I have rarely fired [mostly ’cause 357Mag is too expensive vs. anything else: I might as well practice w/ my 44Mag S&W mountain gun for the ammo costs] but which has exhibited no detectable faults so far. The workmanship on the 22lr revolver [the older of the two, purchased sometime in the late ’90s] definitely is somewhat wanting [the barrel leads horrifically, and accuracy is poor at all times] and I would love to get Taurus’ updated Tracker model in 22lr to see if they’ve improved their QC with the redesign, but regrettably, I still live behind the Granola Curtain and it’s not on the PRK’s list of “approved” handguns [which grows thinner year by year. When are the manufacturers all going to agree to pull a Ronnie Barrett & refuse to sell or service to PRK law enforcement until the rights of the citizens are restored? But that’s a different topic…]

Whoever has been in that 686 ought to buy a decent set of screwdrivers. If I handed a customer back that revolver with those screws, I would catch hell. The “finished product” with trashed side plate screws, not in my shop!

Instead of “coating” a 686, why not just buy a beautiful brand spanking-new 586? I’ve always liked blued guns better than stainless, but I suppose stainless gives better corrosion resistance if they are neglected or beat up. I saw the 586 on the S&W site, so I assume they are still being produced?

Geez, reading comprehension problems? Here’s a quote directly from the article:

“But the general idea was to add a protective coating to the revolver, not unlike what people are doing to 1911s and other pistols, to make it more resistant to the elements and theoretically more reliable. We wanted to take an already rock-solid gun and make it as indestructible as possible.”

Nowhere does he say it was coated for the color, as in a blued gun. In fact a blued gun would be a step backwards from what the author is attempting to do, protecting the gun as much as possible regardless of color of the finished product.

How about showing the cylinder face after the range trip? I would like to see if there are “rings” on the front of the cylinder. That alone would make me interested if I didn’t have to clean the pain in the ass residue off the cylinders on my stainless revolvers.

If it is possible to treat the bore with the Nitromet Salt Bath Nitrocarburizing process (NSBNP), can they do the same with the cylinder chambers and apply the NIB-X coating to the outside of the cylinder?

The coating has a Rockwell hardness of 70? That’s amazing. Appearance aside, that alone should make anyone with an EDC sidearm seriously consider this process.

Interesting.

But the only coating I’d ever put on a mirror finish stainless S&W would be Mothers metal polish. =P

Interesting.

But the only coating I’d ever put on a mirror finish stainless S&W would be Mothers metal polish. =P

I have both a 625JM and a 686 7 shot for several years now and both in stainless and shoot them several times a week. Never seen a hint of rust. What conditions are you referring to that could make them prone to rust since most gun makers tout the durability of stainless.

Something about my personal body chemistry oxidizes stainless steels. I first noticed it in my EDC knives decades ago. D2, S30V, ATS-34, S35VN, 154CM, it doesn’t seem to matter, if it spends any significant time in contact with my skin, it will oxidize. Even the stainless slide on my XDM .40 will show oxidation without a fresh coat of oil every couple of days.

Interesting, I have never personally polished the rust off of a stainless steel anything. I carry a model 60 and live at the beach. In the boat, or just laying under an open window it has never shown any signs of corrosion. No one mentioned that those valleys and peaks hold lubricant better, that is another reason it feels so smooth. Hard chrome does basically the same thing and doesn’t change dimensions enough to cause any problems, chamber and “throat” remain the same. Reminds me of Barkmen’s product.

I have both a 625JM and a 686 7 shot for several years now and both in stainless and shoot them several times a week. Never seen a hint of rust. What conditions are you referring to that could make them prone to rust since most gun makers tout the durability of stainless.

Such a sexy gun. Too bad S&W had to ruin it with that stupid frame lock.

All the close up photos of the finished cylinder show uneven color and what look like scratches. Is it just oil, powder residue or fingerprints? How does it look wiped down?

Thanks,

Will

Damn! Good point. I’ll see if I can’t get it out and wipe it down tomorrow and get a good pic. I should have shot photos before I shot it up good. I was honestly so excited about not having to wipe it down that it never crossed my mind.

Please do. I have a PC 627 that I didn’t think could get sexier than it is, not I am seriously questioning that conclusion.