What do you really need to reload your own ammunition? Read on to find out…

SERIES

Part 1: Want to Reload Your Own Ammo? Basic Questions to Consider

Part 2: The Reloading Process

Part 3: The Gear You’ll Need and What It’ll Cost You

Part 4: Brass Cleaning and Preparation to Load

Part 5: Brass Resizing

Part 6: Trimming Cartridge Cases

Part 7: Repriming the Cartridge Case

Part 8: Powder, Propellants, and Pressure

Part 9: All About Primers

Part 10: Projectiles: Materials, Weights, and Styles

Part 11: Seating and Crimping Bullets

Part 12: To Crimp or not to Crimp

Part 13: Final Inspection and Packaging Tips

There is such a fine line between needs and wants. It’s oh so easy to consider something that’s really a “want” as a “need.” You know, like bacon is technically a “want.” Hang on, upon further reflection that is, in fact, a need. But you get the idea.

The first question prospective reloaders always ask me is, “How much will it cost me to get started?” The problem with that question is that it depends. It depends on whether you want to reload for rifle, pistol, or both. It depends on the number of calibers you want to reload. But more than anything, it depends on your personal definitions of needs and wants.

The list of stuff you truly need is actually pretty modest. When I say need, let’s consider the extreme and rule out gear that simply makes the job easier or faster. Those things are “wants” and you can always add that stuff later. Here, I’ll use this criterion to define gear you need: If you can’t SAFELY reload a cartridge without it, then it’s a need.

So here’s the list of gear you need to safely reload pistol ammunition. At the end, I’ll mention what you need to add if you want to reload bottleneck rifle cartridges. We’ll address the benefits of those pieces of “want” gear in a later article in this series.

Cartridge Case Cleaner

When you pick up fired brass cartridge cases, they’ll be dirty. Depending on whether you shoot at an indoor or outdoor range, the relative level of “dirt” will vary. At a minimum, you’ll want to remove any loose powder residue and whatever dirt your brass acquired when it hit the floor. While your brass does not have to be shiny like new, it does need to have the loose dirt removed. That’s because the brass needs to work smoothly with your reloading dies, and when finished, it needs to reliably load into your gun. If brass is covered with sand and Twinkies filling, you’re going to mess up your dies and run into reliability problems later.

If you want to stick to basic needs, you can clean your brass with stuff you already have. Hot water, a plastic container and some Tide (or a mixture of dish detergent, vinegar, and salt) will get the job done. Throw the dirty brass in there, shake the snot out of it, rinse, and dump on a towel for a day or so to dry. It won’t look pretty, but you’ll achieve the goal of removing loose dirt.

Sooner or later, you’ll want a tumbler or ultrasonic cleaner, but you don’t need either right away.

Your brass won’t be all pretty and shiny, but it will be clean enough to reload. To me, this is a hassle that’s not worth saving sixty to eighty dollars on a brass cleaner. These come in various types including ultrasonic cleaners, dry tumblers, and wet tumblers. Since a cleaning machine is a “want” we’ll get into those in much more detail later in the series.

Cost: $0 dollars. Since we’re being hardcore about wants and needs, we’ll assume you can start with a bucket or other container and acquire a fancy case cleaner down the road.

Reloading Press

This component is a need, although you can get started with a very simple and inexpensive single-stage (or even hand operated) reloading press.

Think of a reloading press like one of those old Play-Doh factories. You know, the ones where you dump Play-Doh in a hopper and press a big lever, so it comes out like star-shaped spaghetti. Like the Play-Doh factory, a reloading press is just a device that uses mechanical advantage to squish things together.

A well-used Lyman single-stage reloading press.

You can do these things with a reloading press:

- Press a brass case against a decapping pin to push out the old primer.

- Press a casing into a resizing die that jams the brass back into its original dimensions.

- Press a new primer into the now empty primer pocket.

- Press the casing against an expanding die that opens the mouth just a tad so you can insert a new bullet.

- Press the bullet down into the casing.

- Crimp the casing around the bullet to remove the bell from the expansion step.

What type of reloading press do you need to get started? I always recommend starting with a single stage press. Single stage means the press does one thing at a time. Using a single stage press, you’ll load in batches. For example, you’ll resize all your cases, then prime them all, then add powder, then seat the bullet and finally crimp all of the cases. While it’s more tedious, a single stage press is simple to learn, forgiving, and most important for this discussion, inexpensive.

Cost: $150. These range higher and lower in price, but you can buy a good that will last you 115% of forever for this price.

Die Set

Reloading dies are simply cylinders made of steel that are used like “inserts” with your reloading press. Following from the previous example, they’re kind of like those yellow plastic cutouts for the Play-Doh Factory. As the interior of a reloading die is cut specifically to match the shape of the type of cartridge, you need a set of dies for each caliber you wish to reload.

The reloading dies screw into the reloading press. The press is then used to jam the cartridge case into the reloading die to perform the specific function of that die. For example, there are three types of dies in most pistol caliber reloading die sets.

Many rifle die sets like this .257 Weatherby Magnum kit contain just two dies.

Decapping and Resizing Die

This die does two things in one step. A steel rod right in the center goes through the open mouth of your cartridge brass and pushes out the old blown up primer. The die itself is shaped exactly like the outside of your cartridge brass, and the diameter of the die hole is the exact dimension specified for that caliber cartridge diameter. It “pushes” the brass cartridge back to the proper diameter so it will easily fit in the chamber of your gun.

Expanding Die

The resizing die reshapes the whole cartridge case back into a proper sized tube. But wait! We’re going to have to stick a new bullet in there at some point, right? Will it fit? That’s where the expanding die steps in. This one simply opens the very end of the mouth of the cartridge case so you can fit a new bullet in there.

Seating and Crimping Die

This is another die that accomplishes two tasks. First, it pushes the bullet down into the case to the proper depth, based on how you adjust it. At the same time, it presses the case mouth inwards to remove the mouth expansion created during the expansion step. Some pistol die sets, like Lee Deluxe Pistol Die Sets, have four dies. These simply separate the seating and crimping functions into two separate dies. Treating seating and crimping as separate operations can be a little more forgiving.

You’ll need a set of dies for each caliber you wish to reload. You’ll also need a shell holder for each caliber. A shell holder is a small insert for your reloading press. It slips onto the top of the piston of your reloading press and grips the rim of your cartridge case — holding it snug while you jam the case into the reloading dies. Some die sets include a shell holder, and some do not, so be sure to check and order it separately if needed. You’ll also need a shell holder for each caliber you want to reload.

Cost: $50. Like anything, the cost of die sets varies, but you should have no trouble finding good pistol caliber dies for less than $50.

Powder Scale

A scale is an absolute necessity in my view. Charging cartridges with either too little or too much powder is dangerous! Recipes for reloading use weight measurements for the amount of powder required. Powder is measured in units of grains, which is 1/7,000th of a pound – it doesn’t mean individual kernels of powder. While some basic reloading kits provide scoops of different sizes to measure powder, this method will always be less precise than weighed measures. Sermon over – get a scale right when you start.

Powder scales come in two different types: beam and electronic. Traditional beam scales never need batteries and always work. Electronic scales are becoming more affordable and are pretty darn reliable too provided you keep the batteries fresh. I’ve seen them get wiggy as the batteries start to drain.

You need a powder scale and both beam and electronic ones work fine.

Cost: $75. Scale prices go from $30 to $300 depending on how precise you want to get. You can get a decent beam scale in the $60 to $90 range. Some of the newer electronic scales dip down to $30 or so, but there seem to be a broad variety of good ones in the $125 range.

Calipers

While not included in most starter kits, I think calipers are a must-have item. Available in analog dial or digital, a caliper accurately measures things.

The most important measurement you’ll need to worry about is the overall cartridge length. It’s critical to make sure that your bullets are seated deep enough to feed reliably, but not so much that you reduce interior case volume and risk dangerous over pressure. A reloading manual will tell you exactly how deep to seat each caliber and specific bullet type.

Analog (top) and digital (bottom) calipers for measuring stuff precisely.

Calipers are also handy for checking the diameter of your cases, but generally, your dies will ensure that cases are sized to the right width.

If you are going to reload bottleneck rifle cartridges, you’ll also need calipers to make sure that your resized cases are the proper length before you start to seat bullets. They tend to stretch a bit when you fire and resize them.

Cost: $40. You can get either digital or analog (dial readout) calipers in this price range, and the quality of those is plenty good enough to get you going safely.

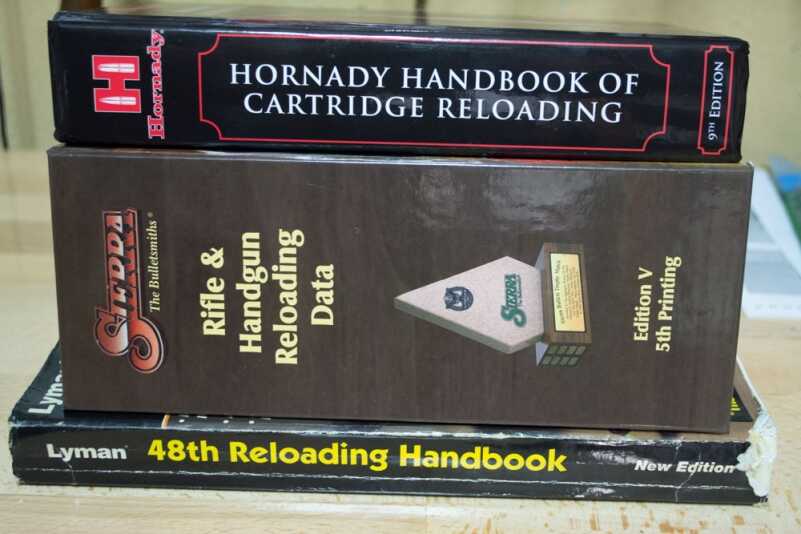

Reloading Manual

Do not reload ammunition, ever, without a reloading manual. Think of this as the cookbook full of recipes for each caliber, powder type, primer type and bullet type and weight. Reloading component and equipment companies like Hornady, Lyman, Speer, Barnes, Nosler, Sierra and Lee all publish books with detailed recipe information. Always, always, always stick to published guidelines for your reloads!

Even though reloading recipes from reputable companies are available online, a book will really help you as it contains lots of additional information.

You can get reloading recipes online, but if you do, stick to data published by the companies that make the bullets or powder. Don’t assume that some recipe from Billy Bob’s Blast ‘Em Up Forum is safe.

Cost: $25.

Rifle Cartridges: Case Trimmer

When you resize rifle cartridge brass, it will stretch a little each time you reload it. So you’ll need to invest in a simple device that trims excess brass from the mouth of the case.

A hand-operated case trimmer like this Forster model will get you started with bottleneck rifle cartridges.

The idea for almost all types of case trimmers is simple. It’s a lathe-type tool, either hand-operated or electric. You fasten the brass cartridge case on the rim end, and a rotating blade trims off the excess brass from the open neck of the cartridge.

Cost: $100. Hand operated case trimmers start at $50 or so and escalate to three figures. The variety of electric and single-caliber trimming tools is too much to cover here, so we’ll stick to the hand-operated model. Besides, like a single-stage reloading press, you’ll use a good manual case trimmer forever.

So there you have it. If I’ve done my math right, we’re looking at about $340 in basic equipment to get started with pistol caliber reloading. Add a hundred if you want to do rifle calibers. Here’s the good news. Companies like Hornady, Lyman, RCBS, and Lee offer reloading starter kits which include different combinations of the gear we’ve talked about here. These starter kits are priced at a substantial discount over what you would pay separately. Kits range from about $150 to $450 or so and vary dramatically in terms of what’s included. Most of them offer more than the most basic “needs” list we’ve discussed here, so you’re getting some of those future “wants” right up front as part of the package.

I notice that you plainly ignored ANY equipment from one of the pioneers of modern reloading: Richard Lee. As to a reloading manual; his is THE BEST, in my experience, for the newer reloaders. It goes into the why, how, and science of reloading. Also covers many brands of powder and bullets, something few others do. They usually only cover what they produce; ie. Sierra, Hornady, Norma, etc. AND, a new reloader can get a fairly complete single stage set for less than $150.00.

There were several comments about the writer \”skipping\” the powder step and discrediting the ability to reload. The title of the article clearly states that it is in reference to the basic components needed to get started reloading. There are links at the top of the article that take you further down the rabbit hole and into the process of actual reloading. The article does an excellent job of describing the basic equipment needed. We all know that there is that one local store that will sell a person anything they can get them to buy. While it isn\’t a crime to separate a fool from their money it is sad to see that some folks will get taken and their experience will leave a salty taste towards something that can be very therapeutic such as reloading. While this is just my two cents worth of advice, many of the fundamentals listed here are sound. All the guys in the comments that say don\’t bother with a reloading manual need to take into account that they could be sending someone with far less experience than theirselves down a very dangerous path. I don\’t mean to hurt anyone\’s feelings with this comment, its just that many of the quality reloading manuals have a lot more information than you can find online and bench space is always a factor with me so I don\’t really have room to set my laptop up and campout there… plus the batteries never run out on the manuals. Just saying. All in all this was an excellent job and I would like to thank the author for taking their time to help get some folks started into the world of reloading.

There were several comments about the writer “skipping” the powder step and discrediting the ability to reload. The title of the article clearly states that it is in reference to the basic components needed to get started reloading. There are links at the top of the article that take you further down the rabbit hole and into the process of actual reloading. The article does an excellent job of describing the basic equipment needed. We all know that there is that one local store that will sell a person anything they can get them to buy. While it isn’t a crime to separate a fool from their money it is sad to see that some folks will get taken and their experience will leave a salty taste towards something that can be very therapeutic such as reloading. While this is just my two cents worth of advice, many of the fundamentals listed here are sound. All the guys in the comments that say don’t bother with a reloading manual need to take into account that they could be sending someone with far less experience than theirselves down a very dangerous path. I don’t mean to hurt anyone’s feelings with this comment, its just that many of the quality reloading manuals have a lot more information than you can find online and bench space is always a factor with me so I don’t really have room to set my laptop up and campout there… plus the batteries never run out on the manuals. Just saying. All in all this was an excellent job and I would like to thank the author for taking their time to help get some folks started into the world of reloading.

I will offer another reason to begin reloading — camaraderie. It is a fascinating hobby with lots of technical details and \”secret\” practices. Sharing these brings you into contact with some great people (I will use this thread as Exhibit A). Only one person at a time can run a reloader, but it takes several people to get you there. Enjoy.

Very True,

I have a lot of friends who love guns and love to shoot but beyond that, there may be little in common.

One friend showed me how to reload and I was introduced formally to the world of steel shooting and three gun type training at the same time…I became instantly hooked and now am currently embarking on the road to competitve shooting.

I have found what separates a shooting enthusiast from a person Who trains with weapons and then reloads ammo to train with those weapons again, is mindset and ethos…They….we, are a different breed. It’s rarely solely about just letting off steam at the range…hell, you can play video games to get your shooting fix. Its about achieving perfection in an activity you love. Most of these guys love to teach and share what they have learned. They love it when they see each other improve…its quite odd to have such a serious hobby/sport be so compettitive yet remain so positive. Ive found nothing but encouragement from the reloading and competetion world and that is hard to say about a lot of people.

I’ve been reloading for over 40 years, and am a certified NRA instructor for metallic & shotshell reloading, that being said. I’m very surprised you didn’t mention the Lee Precision reloading manual, (Modern Reloading, Richard Lee) I recommend it to everyone. Additionally a reloading book such as Lee’s is the most important and first thing a beginner should invest in. AND READ IT, TWICE! Next and also important is to find someone who’s into reloading. If they’re really into it they’ll talk your arm off and be most willing to help you get started.

Just bought a Springfield Armory .45 XD Mod.2 for home defense and I seen a press kit by Lee. Do you think this would be worth the investment if I want to do my own reloads for my .45?

Yes lee is good and you can get their products at good prices by going to factorysales.com The Lee presses are good and fair priced compared to some of the other major brands. Most of the reloading data can be found on line now so you do not have to spend that $30 or so on a manual. You can get used brass at eagle peak shooting range. their prices are fair and they throw in a few xtra in case there is a bad case or two in the lot. They are in Cedar Park, TX. You can find their website and see the prices.

Gonna retire here in a couple years. Gonna need a good hobby to keep me busy once we move to our current vacation home. I’ll be stuck in the house on some cold winter days and can’t fish,so this sounds like just the thing to keep me out of trouble.

I’ve looked into possible starting reloading but just haven’t found the right article to read. Thanks.

Are the reloading die sets and presses standardized and interchangeable, or do you have to purchase die sets that are threaded for use with specific presses? I purchased a couple of dies and a collet from Lee Precision to be able to have a friend reload a batch of 250 old, rare Winchester .348 lever gun cartridges for me, I don’t know exactly which press he has.

Also, the ammo is around 70 years old and has varying amounts of cosmetic corrosion, I’ve pulled all the bullets and discarded the powder and 6 of the cartridges that broke. Tips or advice?

Dies are all standard 7/8-14, with one exception if you plan to reload 50 BMG rounds, you will likely find the dies are larger thread and many presses actually have an insert that can be removed to allow you to either thread in BMG dies or (more common) thread in the Hornady LNL bushing set. Accordingly, yes, dies and presses are all interchangeable – i.e. you can use Hornady dies in a Forester press and vice-versa.

Wonderful article and well written. I have reloaded shotgun shells but always been a little shy about the pistol/rifle reloading. This gives me a little more confidience that makes me want to reload. The comments from the other experienced readers was also very helpful. Thanks, Bill

Good article but they skipped the powder in the list of steps. went from primer to bullet.

It wont cost me anything because I bought all that stuff during the Clinton gun ban administration.

A basic Lee kit, a lee progressive loader and the best one on my bench, a Dillon square deal.

plus a die for each of my caliber guns and all the fixens…

LOL guess you have never used a DILLION PRESS ! Why reload when you can buy new cheaper than the components !

(1) power 7000 grains per pound $35 +

(2) primers $35 + a 1000

(3) projectiles $35 a 100

Bulged Barrel because you forgot the powder ,in your $50,000 1921 Colt Thompson PRICE LESS !

I’m glad I’m not shooting the authors reloads as he does not use powder in the cases.

With havin so much written content do you ever run into any problems of plagorism or

copyright infringement? My website has a lot of exclusive content I’ve

either authored myself or outsourced but it appears a lot of it is

popping it up all over the internet without my agreement. Do you know any

methods to help protect against content from being ripped off?

I’d certainly appreciate it.

I have a suggestion to protect your content – don’t publish it on a public domain called “The Internet” Other than that there is no copyright information outside of published and protected books, magazines, cds, or dvds. The Internet is “public” for a reason and nothing is protected once it hits that. I’m not a lawyer but I have been doing IT work for 25+ years.

Lots of information here for the reloader. I have been reloading around 42 to 43 years. I load for several handgun calibers and many rifle calibers. As far as different equipment goes, I buy the very best out there. My experience is one gets what they pay for many times more than a few. I believe every rifle has a bullet and seating depth it likes, a kind of powder and charge it likes, a primer manufacturer and brass it likes. That being said and the rifle loading for has had the action bedded, barrel floated, and trigger adjusted and all one can do to it that has proven to make it a better performer. I use two scales to weigh the powder because one set can get off easier than one can imagine. Using two only helps to keep each load as precision as I can. I group brass according to manufacturer and weight, trim the brass every time before loading. I resize, deprime and clean the brass in groups. The rest of the process, priming, powder charge, and bullet seating I do one cartridge at a time. On average I clean the barrel every 15 shots for most rifles. Maybe I am a profectionist , but I believe if anything is worth doing I want it done the very best I can. It is not at all hard to prove that factory bullets are not perfect in their construction. No rifle can shoot any better than the cartridge it is provided, I have proved this many times. We all dance to the beat of a different drum, good luck to everyone reloading and keep your powder dry!

“…clean every 15….” then I suppose you don’t do competitive shooting? what a shame, you go to all the great lengths to make everything absolutely perfect…but why? Just to shoot cans and bottles..heck, you can do that with a bb gun.

you are the equivalent of an audiophile…listening to music on a machine that is 20x more expensive than the instruments that made the recording.

I like this article. great subject.. and I probably can get just as good as reloading results on my equipment ive been using for 25 years. my only upgrade since the time I started was going to an electronic scale and ditching my balance beam. Oh, yes, I traded in the tumbler I made out of a #10 coffee can and a bbq rotisserie motor, for a cabelas vibratory machine.

I’ve been considering buying a very basic set up to reload .45 Colt with black powder. I was looking at the Lee site, and they have what are called Lee Loaders that are not presses, but then they sell for only about $40. I can’t figure it out from the site (so if anyone has experience with one of these, please post a reply), but I gather that one uses a rubber mallet for the “pressing” action. Is my guess correct, and how hard are these to use?

I have one of the Lee Loader kits in .45 Colt, and it works as you describe. It’s a brilliant little piece of gear and all the functions you need are wrapped up in one double-ended cylinder. You just flip the cylinder end for end at the various cycles to perform the necessary tasks. Works like a charm. It is however slow, but on the plus side, I picked mine up at Amazon I think for $30, so great deal for the price. You can easily load 100 rounds in an hour, maybe more, I don’t have the need to rush it, and it’s a great way to into reloading to find out if it’s really for you. You are also correct that mallet (I have a plastic one) is used to provide the necessary “pressing” action.

I have about 35 years of reloading under my belt. I started when I was about 10. I reload several different pistol, rifle and shotgun calibers/gages. My Father found that it was a good way to keep me out of trouble through my teenage years so he fostered the hobby….which so many youth need so badly nowadays(Fathers and Hobbies). Since most of my gun handling life, I have reloaded, It’s just what I do now. I seldom ever buy factory ammo. I can definitely say that “expense” is probably the least of all reasons to get into reloading IMHO. I guess I find great satisfaction in the process of doing it myself and in experimenting with different loads/guns. I still get a kick out of shooting small groups with ammo I have loaded. I have a hard time putting a price on that. While this is possible with factory ammo now….it just feels better when you loaded it yourself. I am doing the same with my son, now. My point is…if you are worried about expense, DON’T get into reloading. My equipment has paid for itself a few times over the years. But if I lost it all tomorrow, I would start it all over again, no matter the cost. Good Article! Keep them coming. And yeah, don’t forget the lube!! LOL.

Is there a press that works for pistol, rifle, and shotgun shells? Thank you.

Rifles and pistols use same system and basic parts. Shot shells have to be done on a dedicated unit. MEC is probably the simplest and best you can get. They last a lifetime.

I recently (within the past 18 months) took the plunge and got into reloading. I find it neither difficult nor time consuming. I can crank out 200 rounds of 9mm or .45ACP in a little over an hour, and do it a couple times of month for a couple hours a day. I find the process very relaxing. You have to pay attention, but the rhythm and flow of the process, and having the bench area all to myself without disruption is a very pleasant way to spend an evening or two a month.

In your start up list, a few things that I find essential include:

1. Primer flip tray: https://www.dillonprecision.com/dillon-primer-flip-tray_8_3_23608.html

2. Primer Pick Up Tubes: https://www.dillonprecision.com/dillon-4-small-pick-up-tubes_8_3_23517.html

3. Bullet Puller (for when I make mistakes): https://www.dillonprecision.com/berry-s-kinetic-bullet-puller_8_3_23998.html

4. Stainless Steel Case Gauges (a little bit more comprehensive size check than just calipers): https://www.dillonprecision.com/dillon-handgun-case-gages_8_3_25548.html

I quote from Dillion’s site, you can obviously and easily find cheaper sources, but few better than Dillon to actually work with.

Another tip I learned is that crushed walnut shells makes a great cleaning media in the case tumbler, and can be bought cheap from pet shops that sell bird supplies.

BTW, the press I bought was a used Dillon 550B. It’s been fantastic. I have probably produced 6,000 rounds on it over the past 18 months, and it had a lot of milage on it when I bought it, and its still going strong. I have two sets of dies (9mm and .45) and it’s easy to swap out the dies, toolhead, base plate, powder horn, and primer tube to change between calibers.

All up, it cost me about $1,000 to get into reloading in a serious way, but that includes the reloader, the items in this article, and my first stockpile of powder, bullets, primers, reloading books, etc…. I have already hit the break even factor and then some. And the process is enjoyable and relaxing. If you can swing the coin, you won’t regret getting into reloading. Or just do what I did, sell a seldom used gun or two, in exchange for reloading supplies for guns you use a lot, or wish you could use more often. Once you start reloading, you will be surprised how often you can go shoot. I don’t think twice of swinging by the range on my way home and popping off 200-300 rounds. It trivializes the cost of ammo, and that is a good thing!

I recently (within the past 18 months) took the plunge and got into reloading. I find it neither difficult nor time consuming. I can crank out 200 rounds of 9mm or .45ACP in a little over an hour, and do it a couple times of month for a couple hours a day. I find the process very relaxing. You have to pay attention, but the rhythm and flow of the process, and having the bench area all to myself without disruption is a very pleasant way to spend an evening or two a month.

In your start up list, a few things that I find essential include:

1. Primer flip tray: https://www.dillonprecision.com/dillon-primer-flip-tray_8_3_23608.html

2. Primer Pick Up Tubes: https://www.dillonprecision.com/dillon-4-small-pick-up-tubes_8_3_23517.html

3. Bullet Puller (for when I make mistakes): https://www.dillonprecision.com/berry-s-kinetic-bullet-puller_8_3_23998.html

4. Stainless Steel Case Gauges (a little bit more comprehensive size check than just calipers): https://www.dillonprecision.com/dillon-handgun-case-gages_8_3_25548.html

I quote from Dillion’s site, you can obviously and easily find cheaper sources, but few better than Dillon to actually work with.

Another tip I learned is that crushed walnut shells makes a great cleaning media in the case tumbler, and can be bought cheap from pet shops that sell bird supplies.

BTW, the press I bought was a used Dillon 550B. It’s been fantastic. I have probably produced 6,000 rounds on it over the past 18 months, and it had a lot of milage on it when I bought it, and its still going strong. I have two sets of dies (9mm and .45) and it’s easy to swap out the dies, toolhead, base plate, powder horn, and primer tube to change between calibers.

All up, it cost me about $1,000 to get into reloading in a serious way, but that includes the reloader, the items in this article, and my first stockpile of power, bullets, primers, reloading books, etc…. I have already hit the break even factor and then some. And the process is enjoyable and relaxing. If you can swing the coin, you won’t regret getting into reloading. Or just do what I did, sell an seldom used gun or two, in exchange for reloading supplies for guns you use a lot, or wish you could use more often. Once you start reloading, you will be surprised how often you can go shoot. I don’t think twice of swinging my the range on my way home and popping off 200-300 rounds. It trivializes the cost of ammo, and that is a good thing!

Why did you go with Dillion? The most press that I’ve seen is for Lee and RCBS and I’d never heard of Dillion before.

Bill, I chose the Dillon based on advice from another shooter with a Dillon. Part of what swayed me was the lifetime support of the product, regardless of who bought it. Sorta like the warranty on a SnapOn tool. If it’s broken, they will fix it. No questions asked. Dillon has an excellent website, good support info, and they answer their phone. The other convincing aspect was the ease of operation. It’s a 4 stage press, so it’s highly efficient. I chose the 550B over the more expensive, more automated 650XL because I tend to prefer manual things with a perceived durability factor. Also, the quantity of shooting I do doesn’t really justify the need for a automated set up. I don’t produce thousands of rounds a month, only a few hundred, so the manual press works perfectly for my volume of use. Finally, the last aspect is of lesser importance, but they sell caliber kits that make swapping between calibers really easy. I knew up front that I wanted to load more than one caliber, and while some folks buy multiple, dedicated presses, I can’t justify that with my low volume of use. But I do alternate enough that ease of use in swapping between calibers was definitely a consideration. I can swap calibers in under 30 minutes, with several test rounds and tweaking between setups to get things “just so”.

I to own a Dillon 550B plus a Hornady single stage. Gotta love the Dillon quality and warranty.

Bill:

Beware, Dillon has a cult like loyalty with their owners; in case you did not discover that based on the responses already. The primary reason you haven’t heard of it is because it is not sold in large stores (i.e. Cabela’s Outdoor World, Bass Pro, etc.) Dillon sells direct and there are only a handful of dealers. It is known for excellent customer service, but almost every brand out now has excellent service – conceptually they have to, this is a niche market after all.

Best press is the press you like and own. If that means you can only afford Lee, then Lee is the best press for you. If you need 5 stations and auto indexing, then Hornady is the best press for you. If you want a green press . . . . well, you get the idea. All are good, all make great ammo as long as you put in the time to dial it in and set it up and all will make ammo that will destroy your gun and ruin your day if you are careless.

LOL! Some people are to dumb to even know how dumb they are ! Bill bets his life on RG-Jennings-Raven-High Power guns also and drives a YuGO car ! Bet he has never used a Dillon PROGRESSIVE LOADER ! Why shoot a muzzle loader when you can shoot a machine gun ! Like Bill said \’TIME \’ if you had rather spend time loading than shooting !

I just pull the handle 50 times and get 50 rounds of ammo ! With the motor I just flip the switch and my 1050 takes less than 30 seconds ! This heavy duty machine is capable of loading 1,000 to 1,200 rounds per hour !Dillon Precision

Dillon 550B Reload press setup with strong mount YOUTUBE

Reloading 100 rounds of 9mm using my Dillon XL650 press in less than 5 minutes! YOUTUBE

Motorized Dillon Super 1050 Custom Made autodrive YOUTUBE

Motorized Dillon Super 1050 Reloading Press Operating YOUTUBE

————————–OR————————————————–

Here is a few for the PROFESSIONALS Like Bill !

Lee Classic Rifle Handloader – get into the hobby for short money! YOUTUBE

Portable Outdoor Reloading Kit – Lee Hand Press YOUTUBE

I have been reloading for over 40 years and have numerous presses and dies. My go to has always been my “Original Lee Loader” when it comes to reloading a small quantity for hunting. I do utilize a scale along with a powder trickler when preparing any loads. So if you need to load small amounts of ammo I would suggest going this route if you are using brass from your own guns. You will save a huge chunk of change over investing in a press and dies.

Overall a good article, and as you indicate that more is coming, some of the comments made and questions asked may be resolved. Your opinions seem to be based on a long history of reloading for several, if not many guns so I thought I might offer some thoughts at the other end of the scale; indeed, some of your “needs” I might consider as “wants.” I started reloading over 30 years ago for one gun, my .30-06 M70, in a small – essentially one-room – apartment and I recall it well. With minimal equipment I produced ammunition that gave me sub-one inch groups at 100 yards, more than what I needed for hunting. So…

Case Cleaning: unless you shoot semi-autos and/or like to scrounge brass others have left behind this is a non-problem.

Reloading Press: yes, a single-stage is the way to go, if you have a place to set up a bench. Otherwise, a handheld press or even a unit like the Lee Loader (which I used) will suffice to start.

Dies: No need if you go with a Lee Loader.

Powder scale: Only if you are a perfectionist and/or want to vary charges to achieve better accuracy/performance. Otherwise, a set of powder measures is cheaper and will deliver acceptable results.

Calipers: These are great tools to have for any shop and can be had for less than the $40 cited. On the other hand, unless you are using cast-off brass or re-using your own brass many, many times, they are unnecessary. As for OAL, use whatever factory load you are starting with (where else do you get those empties?) to adjust your loader or dies and go from there.

Reloading Manual: Absolutely, but if you don’t have specific bullets, powders, and primers in mind you may need to acquire several manuals.

Case trimmer: Only if you intend to reload many, or at least several, different cartridges for more than one gun, and re-use your brass many times. There are trim dies available for much less if you only reload for a few guns and calibers.

Unless you get carbide dies, you are going to need a way to lube the case before sizing. Otherwise you will stick the case in the die and you will really be messed up!

I use PAM vegetable oil spray for case lube. It’s cheap and can be purchased at any grocery store for next to nothing. You only need a large plastic bag, put your brass in it (50-100 cases at once), squirt in a little PAM, mix the brass up and go to work. It gets the sizing die nasty but a little mineral spirits and compressed air fixes that. I only lube my rifle cases though – pistol dies are carbide (Lee) so lube isn’t necessary.

Also, for some it’s not the cost to reload but the desire to have total control over the experience.

When I see what they want for 300 blk (especially subsonic) I know a lot of cash can be saved by reloading with a cheap setup.

I would like to know how you have been bought. I have loaded over 10,000 rounds of different calibers using the Lee turret Press kit (cost 210 for the entire kit. Use an ultrasonic cleaner from harbor freight and a tumbler with stainless for finishing. now I am up to maybe $400. I prefer the turret because you can stop and remove the case at any point in the process to check for consistency.

I started to look into reloading, This is what I have found out. Okay, to start with you need to sit down and figure out how many rounds you shoot a week, month, and year… If you shoot less than 1000 rounds total a year don’t bother investing in reloading because it is way too much work and it will take 80 years to recoup your money…(depending on what you get for equipment) The only reason you might want to reload shooting less than 1000 rounds is for “Long-Range-Hunting” where you need a precise special load for hunting that will recoup your money by putting food on the table… (400+Yards) Other than that Don’t bother… Now if you shoot lets say over 2000 rounds now, Then you should first go on facebook, craigslist, Meetup, or anywhere else you can think of to find someone in your area that reloads and see if you can “Help them” to try it, as it looks real easy in the adds and on youtube, but to start from scratch and go through and set up and buy all the stuff needed and go through all the process’s from start to finish, it’s a “Whole-lotta-Work”!! That said, if you have hours and hours to spend doing this you may love it like my friend does and he doesn’t have children so he doesn’t need to tear down everything and put it away each time like people with kids would… One thing, I personally think I will not get a single press, as my time is limited and valuable I’ve contacted the 3 “Major” reloader makers and let them know what I’m looking for, and they are close to making the system I’m looking for. It’s between the “Blue”XL650 (if they come out with a “Bullet Feeder” to make it completely auto with all censors, and alarms.) And the “Red” “L-N-L” Ammo Plant, (They need to come up with more censors and alarms, and some how they need to make it easier to swap Cal.) I’m waiting for “Green” to come out with something, and they all have until next “Shot-Show” here in Las-Vegas… As next spring I should have a settlement check and will buy one of them. Don’t get me wrong I may get a single chucker if I get into “Long-Range” Shooting .300WM… But I plan to shoot around 3000 9mm, 1000 .40, and 5000+ .223, 2000 .308 and maybe more a year… So I also recommend going in with someone if you both shoot different Cal. You buy the press and the main Cal you shoot and let him/her buy the rest of the Cal Sets… That way you can turn out a few hundred rounds per hour once set up… That way if you spend 4 hours a week you can go shooting once a month and if you shoot a lot you will eventually get your money back and maybe save some too. Hope this helps someone… I will be doing a video from the time I Buy my stuff to when I turn out my first complete round…Good Luck….

While I agree the amount you shoot is a large factor in how long it takes to recoup the investment, the bigger factor is WHAT you shoot. If your preferred weapon is a 9mm consider this – ammo can be bought for about .25 – .30 per round and it cost about .10 -.15 to reload so doing the math, it takes about 3,350 rounds to recoup the cost of the equipment (assuming $500 in equipment cost). BUT, reload 7mm Rem Mag that cost $2.25 per round at the store and can be reloaded for .50 ($35/box savings – yes you can buy cheaper, but my rifle is picky, it likes Barnes TTX). I also own two.41 Mags which burn ammo at a buck a round that can be reloaded for .30 so in this case the volume to recoup cost changes significantly. This of course assumes cost is your only concern – I live in a house with two women and a neutered cat, an hour or two in the garage pressing rounds is a good way to relax.

Bottom line, there are many reasons to reload and cost may not be the first one on the list, if it is, then splitting cost with a few buddies should be considered.

Another reason to reload is that your caliber may not be easy to find, and just when you want to go shooting… oops! Nobody’s got your ammo. Just sayin’…

I do my own loading for several reasons and I think all hand loaders would agree on most. 1. Cost savings is pretty good depending on how much you shoot. I save anywhere from 30% on up by doing my own. My .223 Rem rounds cost me about $0.192 per round at this time but I’m working on getting that down. 2. I have control over the loads at all times. After getting 2 (yes, I got 2) squibb rounds within a couple months from store bought ammo (I won’t mention the MFGs but they are two of the most popular). Fortunately I didn’t lose a hand or a gun over it but it’s pretty scary nonetheless. Getting one squibb is a fluke but two is something else – and with two different manufacturers and two different guns. I decided right then that I was going to control that by loading my own. Several thousand later I’m still shooting my own. I have complete control over each load and it gives me peace of mind over “trusting” someone I don’t know to do their job right 100% of the time. 3. It’s fun. It’s fun locating components at discount prices, it’s fun cleaning the brass (weird, right?), it’s fun testing and tweaking new loads (I use a Chrony for velocity measurements to get it right) and it’s just fun building it. And, I use a single stage Lee and refuse to do upgrade to a progressive or something faster. I use a Harbor Freight ultrasonic cleaner, my own recipe for cleaning solution, Frankford Arsenal vibratory tumbler, pet store walnut shells with NuFinish for polishing. My brass looks like jewelry before I start to use it again. I use primers from whoever sells them cheap and have never found a difference with velocity between any of them and I’ve tried them all. I now use S&B and have zero issues and save upwards of $10/1000 – more when they go on sale.

In other words, I do this for safety, savings, and it’s fun.

I recommend picking up a RCBS Rock Chucker Supreme kit; it costs around $300. It comes with nearly everything you’ll need to set up a reloading bench; add a set of dies and a case cleaner and you’ll be set as far as tools. I’ve found that I can reload just about any caliber for less than I can buy factory ammo, with the exception of .223 and AK47 (7.62×39). Either save your brass from your factory ammo or buy the cases new. A sleeve of 100 count primers will run about $3.00; the biggest challenge will be to find pistol powder, but patience will pay off on that.

I suggest walnut shell for case cleaner media, and you can pick up a 50 lbs. bag at a animal feed store for about $20. For pistol calibers, I suggest RCBS dies. They work great and all have a carbide lining inside to prevent stuck cases. For rifle, I like Hornady, but RCBS will work also. Hornady has a free bullets program for Hornady reloading purchases. All dies have the same threading for your press.

If you shoot routinely, the investment to get set up will pay for itself within multiple boxes of ammunition. The bigger the caliber, the more you’ll save. Also, custom loads now become an option. I hand load light loaded 38 special for a friend of mine whose wife has a Ruger LCR and is recoil sensitive, and she loves them. I’d skip buying the manual as you can find load data for all popular powders online for free.

Now that I have invested the time needed to learn how to reload, I rarely buy factory ammo, enjoy custom loading for friends, and save myself a lot of money for what can be an expense hobby for non-reloaders.

I’ve been “threatening” to reload for over forty years. Actually purchased an old, basic Lee Loader set with necessary components for .38 Special. Thirty years later a hurricane took it all and saved me the problem of disposing of an unopened, 30 year old can of powderand pistol primers. Anyway, this is the best of many “start-up” reloading articles I’ve read over those years. MAYBE I’ll get started soon. Not giving any odds on it but if I do this article will be used as a basic plan. Thanks.

Great read…I’m using a pretty cool 3-in-1 trimmer (Trim-It II) that’s only like $150 for my .308 and .300 blackout brass. Those old lathe trimmers don’t cooperate with me anymore.

Great write up but I have kept this one away from my wife as some of what you call wants I have already sold as needs. With regard to cleaning brass: as of late I have been using the vinegar, dawn, and salt mixture and my cases are every bit as clean as they were prior to my sonic cleaner giving up the ghost. The one thing that I noticed is that I was getting a lot of post wash tarnish or reddening that no amount of rinsing was removing and then I remembered my 7th grade science and started neutralizing the acid bath with a baking soda bath immediately after the acid bath and the 1st rinse and now all is well. Just sharing. Happy reloading.