When you mount a new optic, step one is to zero the scope.

THE SERIES

- Part 1: Optics Buying Guide: Iron Sights, Red Dots, and Scopes

- Part 2: Optics Buying Guide: Top Must-Know Terms for Picking the Right Scope

- Part 3: Optics Buying Guide: Scope Mounts

- Part 4: Optics Buying Guide: How To Properly Zero Your Scope

- Part 5: Optics Buying Guide: Finding Your Range with a Scope Reticle

- Part 6: Optics Buying Guide: Hold Off vs. Adjustable Scope Turrets

- Part 7: Optics Buying Guide: Scope Reticles

- Part 8: Optics Buying Guide: Using a Laser Rangefinding Scope

- Part 9: Optics Buying Guide: Holographic and Red Dot Optics

- Part 10: Optics Buying Guide: AR-15 Optics and Scopes

- Part 11: Optics Buying Guide: Big Scopes

- Part 12: Optics Buying Guide: Do You Get What You Pay For?

The process of zeroing scopes causes a whole lot of grief and aggravation, not to mention wasted ammo. I have to wonder if the reason for this problem is that it involves math, and most of us shut down on the whole math thing about half way through eighth-grade Algebra.

So, what exactly is zeroing?

Simply put, the process of zeroing a scope matches the point of aim to the actual point of impact. Put differently, the process ensures that a bullet lands exactly where you put the crosshairs. As bullets drop (because of gravity!), we need to make some decisions about how we want to adjust our scope so that the crosshairs reflect the point where the bullet will actually strike. Usually, this involves aligning the scope and rifle so that the rifle slightly “lobs” the bullet up relative to the line of sight.

The test rifle for these examples was a Volquartsen 17 WSM Deluxe with a Burris Veracity 4-20×50 scope.

To illustrate the process, I decided to bolt a new scope on a rifle of known accuracy and walk through the zeroing process, making some notes and taking some photos along the way. I’ve got a loaner 17 WSM Deluxe Semi-Auto Rifle from the folks at Volquartsen that I’m really having trouble returning. That’s because it’s smokin’ hot. The .17 WSM rimfire cartridge launches projectiles at just a hair under 3,000 feet per second, and the accuracy is stunning. This rifle also makes a fantastic optics platform as the mounting rail is machined into the receiver, so there are no bolted on parts.

I wanted to make a rock solid platform for a Burris Veracity 4-20×50 scope so I used XTR Signature 30mm rings. These are built like tanks, and once mounted, nothing is moving.

I mounted the Burris Veracity with Burris XTR Signature rings.

So at this point, I’ve got a rifle with a fresh optic installed that’s never been fired in this specific configuration. The very first thing I’ll need to do is zero the scope. Let’ walk through the process.

One more thing. There are shortcuts that will get you pretty close, but in the interest of science, we’re going to cover the tried and true, and more precise, method here. Once you know the details, you can later decide whether shortcuts are appropriate.

Step One: Determine your optimal zero distance

There is no right or wrong distance when it comes to setting the zero on your rifle. The correct distance all depends on how you plan to use it. For example, the “right” zero distance on a typical AR-15 type rifle might be anywhere from 25 to 200 yards – depending on what you want.

I like to figure out my “perfect” zero distance for a given rifle by looking at the trajectory calculations. Ballistic calculators like the free online Burris Dope Card allow you to play with variables like zero distance to see how your bullet will fly relative to the line of sight over distance. Tools like this require a few pieces of information like the caliber, bullet type, height of the center of your optic over the center of the bore, temperature, elevation, and actual velocity of the projectile from your particular rifle. After taking in all this information, the tool spits out a table showing how many inches your bullet will drop at different distances as it travels down range. Depending on your zero settings, you may see some positive numbers that indicate the bullet is above the line of sight. That’s not because bullets rise, but rather because the scope and rifle are aligned in such a way that the rifle slightly lobs the bullet up a bit relative to the line of sight through the scope.

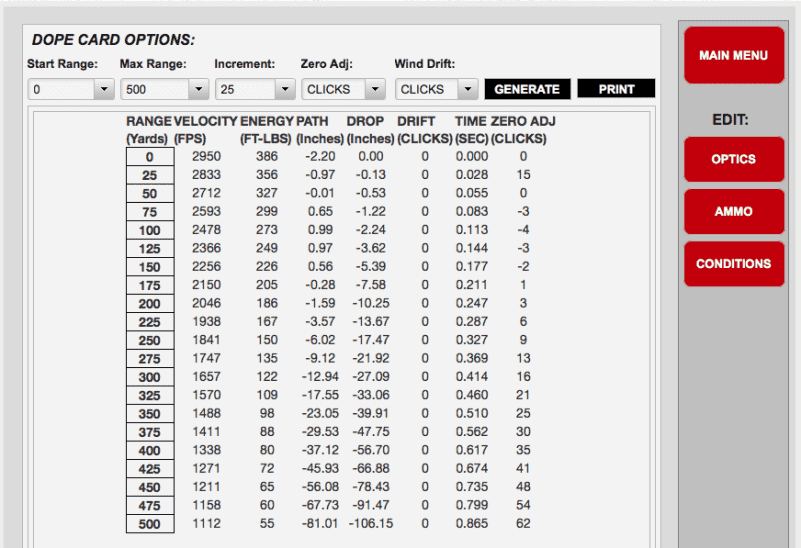

I used the free Burris Dope Card tool to look at trajectories for the 17 WSM. Here’s the data for a 50-yard zero.

I used the Dope Card tool to look at trajectories for my test setup. I used Hornady’s 20-grain .17 WSM V-Max ammo, so I selected that profile from the tool’s database. The Burris Veracity scope, when mounted with the XTR Signature rings, was exactly 2.25 inches above the bore. I measured velocity with a chronograph at 2,950 feet per second. Entering all that, along with the temperature and elevation spit out the trajectory table shown here. I chose a 50 yard zero mainly because the path of the bullet would be within an inch of the line of sight at any distance between 50 and 200 yards.

Step Two: Fire a group

First, always fire a group rather than a single shot when zeroing. If you fire just one shot to zero an optic you’re already chasing a phantom. Here’s why. Let’s say that the accuracy of your rifle is two minutes of angle. That’s two inches of potential variance at 100 yards. If you fire one shot, then make a two-inch adjustment on your scope it’s entirely possible that your next shot could land right where you started on top of the first one. Or, you may pull the shot. Or the yahoo in the next shooting lane might bump your shooting bench. Or whatever. Just fire three shots so you get a good average indication of where your bullets are impacting.

For this example, I fired a three-shot group at a target 50 yards down range. Although I was careful and used a good rest and rear sandbag, I did manage to pull one shot a bit as you can see in the photo. That makes my point, however, as to the importance of firing a group when zeroing rather than a single shot. Whether shooter, ammo, or gun, there is always a bit of variance in the process, so averaging a group will give a better overall result.

The Burris Veracity 4-20×50 scope with XTR Signature rings.

Step Three: Where is it?

If you remember your high school geometry, feel free to use that to find the mathematical center of your group. If you didn’t bring your protractor to the range, just eyeball it.

At this point, we want to see how many inches we need to move the point of impact both vertically and horizontally to get the group to the right spot on your target. Here’s a great opportunity to plug those “sight in” targets that are laid on a grid of one-inch squares. Through your scope, you can easily see how many inches you need to move the point of impact – you don’t have to retrieve the target and measure. Besides, no one brings rulers to the range.

Step Four: Figure out where the bullet impact needs to move

Referencing the photo, you can see that my group impacted about seven inches to the right and 2 ¾ inches below the original point of aim. So, we need to “move” the point of impact up 2 ¾ inches and left about seven inches. Fortunately, this is exactly how the turrets or dials on your scope are marked. When you see an arrow that points in one direction and says “Up” or “Right” that means turning the dial in that direction will “move” the bullet’s point of impact in that direction. Forget about what the crosshairs are doing inside the scope. Rather, just think in terms of moving the bullet strike “up” and to the “left” in this example.

My initial point of aim was the upper left target. The first group impacted seven inches to the right and 2.75 inches low.

Step Five: Adjust the turrets or dials

The Burris Veracity in our example is clearly marked on the turrets with “1/4 MOA.” That means that each click will move the point of impact ¼-inch at a distance of 100 yards. Since we’re shooting at half that distance (50 yards), each click will only move the point of impact half of the prescribed distance, or 1/8-inch.

Most scope dials will indicate the amount of adjustment per click. This Burris Veracity adjusts 1/4-inch at 100 yards per click. Also note the “Up” arrow. This indicates which way to turn the dial to move the bullet strike up on the target.

Now it’s math time, but fortunately, it’s really simple. We need to move the point of impact seven inches to the left, and each click moves the group 1/8-inch, so ipso facto E. Pluribus Unum, we need to turn the windage dial (on the side) 56 clicks in the “left” direction. We also need to adjust the elevation to move the group’s point of impact up about 2 ¾ inches, so we’re going to move the elevation turret (top) up 22 clicks. That’s 16 clicks for the two inches plus six clicks for the ¾-inch adjustment. Make sense?

Step Six: Fire another three-shot group

If we did our measuring and math correctly, we should be pretty darn close to right on target. Looking at the photo, we are, in fact, pretty close to the bullseye. You’ll see that my measuring and math skills put me about ½-inch left of a perfect bullseye. Since this is an accurate varminting rifle, and I might want to do head shots on mosquitos, I’m going to move the point of impact four clicks (1/2-inch) to the right, and I should be good to go.

After adjustments, the group landed only 1/2-inch left of the point of aim – note upper left target.

Step Seven: Verify

Since I’m picky and want to know exactly where my bullets still strike, I’ll shoot one more three-shot group just to make sure everything is hunky-dory. If you plan to shoot at significantly longer ranges than your zero distance, it can’t hurt to zero precisely. As your range increases, the error in your zero multiplies in linear fashion. So if you’re ½-inch off at 50 yards, you might be one-inch off at 100 and two-inches off at 200. Besides, nailing bullseyes is fun, so feel free to spend a few extra shots getting as close to perfection as you can.

Other zeroing bar tricks

Sometimes you may not have a range long enough to zero your rifle at the desired distance. Suppose you want to zero your gun at 200 yards, but you only have access to a 100-yard range. No problem! Math can work for you again.

Earlier we talked about using a ballistic calculator app to determine the trajectory of your specific ammo so you could make a good zero distance decision. You can also use that same app to solve the problem of zeroing for 200 yards (in this example) while using a 100-yard range.

Using the Dope Card tool, enter the distance that you want to zero (200 yards) and make sure the other settings for bullet type, velocity and such are correct. Now look at the trajectory table. In my example, shooting the 20-grain Hornady V-Max .17 WSM, the chart indeed shows zero bullet drop at 200 yards, which correctly indicates the calculated zero point. If I look at the value for 100 yards, the chart shows me that the bullet will be flying about 1.8 inches high at that range. Using a grid target, I can simply adjust my scope so that the point of impact is 1.8 inches above the point of aim. Essentially, we’ve matched the calculated trajectory curve of a 200-yard zero. Since we did this using math, we’ll want to verify at the soonest opportunity that the point of impact is actually where we expect when shooting at 200 yards. Using this method will get you pretty darn close, but as ballistics is 80 percent science, 54 percent art, and 73 percent pure voodoo, it’s always good to check when you have the opportunity.

I have the Dope Card tool set up for a 200-yard zero. At 100 yards, the bullet should strike 1.79 inches high.

This basic concept also works at extremely short range. Depending on the sight or scope height above the bore, cartridges like .30-06 and .308 will often have “zeroes” at 25 yards and 200 yards. Your ballistic calculator will tell you the exact distances, but when you lob a bullet, it crosses the horizontal line of sight twice – once on the way up and once on the way down. Many times, the “up” crossing event will happen around 25 yards. If you’ll look at the image of my trajectory chart for the demo .17 WSM load here, you see that the “up” crossing point happens at 50 yards because this bullet is moving exceptionally fast and doesn’t require as much of a lob as a larger and slower projectile.

Closing Thoughts

The whole concept of zeroing can be confusing, but if you remember a few key things, the process is much easier. Remember when moving the dials on your scope that the indicator arrows reflect the direction that you want to bullet strike to move. Always check your scope to see exactly how many inches each click will move the point of impact at 100 yards. Then, rather than guessing and madly spinning dials like a Wheel of Fortune contestant, you can calculate the number of clicks you need and get on target quickly and easily. I’d much rather burn through my ammo in the verification and “fun” stage rather than just trying to get on target, right?

Article ! Was in deference to Yogi. I used to shoot benchrest with Harold Shipley of Alamogordo , New Mexico. He had a small brass hammer that he would use to ” tap ” the unertl after every adjustment.

Love the ballistic comment. Yogi said ” Golf is 80% mental and the other half is in your head . ” Great artical

Adjust the scope X to the initial point of bullet impact after bore sighting.

With an AR and a laser sight, it’s very easy.

Mount the scope and laser (a green laser is more visible over a greater distance in daylight).

With the scope’s crosshairs on the center of the target, fire a five-round group.

Keeping the crosshairs on the target, adjust the laser so it points at the middle of the group.

Adjust the scope so the crosshairs are on the laser. (This last step doesn’t even require you to remain on the target, just perform it at the same range as the group was fired. This makes the step less fidgety.)

That’s it.

Your method is right on. I shoot a 35 Whelen, a 20 gauge slug gun and a 495 grain muzzle loader round. Between recoil and cost of ammunition I find your method to do best for me. There’s not but so much recoil one can take and not flinch after a bit of time. These people are shooting many rounds a session just for zero purposes. My slug gun is almost three dollars a round for the slugs it likes. Three bucks a pop kinda takes the fun out of range time for an old retired guy. I was surprised your method was not the method covered. Happy range days to all!!

I find it easier / handy to start with a laser bore site; although that’ll only give you the straight-line shot. But if you believe your bullet will cross the line of site at 50yds or so, then set the target at that distance and site it in with the bore site. Then move the target (or yourself) back and adjust as needed w/ real bullets. Cuts down a lot of live fire, trying to get started.

Good piece. Been mounting scopes since 60’s, didn’t start “lapping” rings until 30 years or so ago after really looking at some of the scopes I had swapped out, or received from others, and saw how bad some of them had deep “rings” scored in them and/or bright spots on the tubes due to the condition of the inside of the rings Of course, the outside always looks good. I never really noticed a pattern in which rings seemed to need the most work, I just lap all of them now, I try for at least 70-75% bearing/contact surface. Although the manufacturer of my tool (Sinclair) recommend lapping only the bottom of the rings, I’ll also work on getting the “high” spots off the top ring as well, just makes sense to me. Works fine for me, your milage may vary…… Pop

Stg. Pop looking for info. on lapping scope rings. Sandpaper grit??

I have to mention something else here that’s missing: Your scope rings out of the box are probably not going to be precisely concentric. They will be slightly out of round and elliptical. That means you’re going to have to take a one inch dowel wrapped in sandpaper to true inner circumference of the scope rings so they will close properly: I didn’t do that, so I ended up over-tightening the scope rings and denting the tube. Still works but you can see the marks left by the rings.

Awesome information. I can’t wait to try it out.

I’ve learned that before starting to zero your aim point, zero the cross hairs in the scope by rolling the turrets all the way to one stop, then counting the clicks to the other stop (doing it both vertically and horizontally). Then with the turret at one stop, click off half of the total number of clicks to center the cross hair in the scope. Gives you the widest initial adjustments for zeroing the aim point.