Estimated reading time: 11 minutes

At 7:30 p.m. on 3 July 2023, North Carolina State Trooper Jeffrey Dunlap pulled to the side of Interstate 26 to assist what he assumed to be a stranded motorist. The driver, Wesley Scott Taylor, then inexplicably produced a .44 Magnum Desert Eagle handgun and shot Dunlap in the chest at near-contact range. The massive 240-grain jacketed hollow point flattened on Trooper Dunlap’s armored Kevlar vest.

Despite having been centerpunched by a .44 Magnum round, Dunlap drew his service weapon and killed Taylor in the subsequent exchange of fire. The only reason Jeffrey Dunlap, a distinguished 13-year veteran of the Highway Patrol, got to go home to his family that evening was that he was wearing superb state-of-the-art soft body armor.

Table of contents

- Origin Story

- Catching Attention

- A Visionary

- Kwolek Makes Kevlar

- But What Could You Actually Do With Kevlar?

- READ MORE: Biden’s Joint Speech to Congress: What do you think deer are wearing kevlar vests?

- A Vested Interest in Survival…

- READ MORE: Eberlestock Bulletproof Backpack

- The Rest of the Kevlar Story

- Things End Well For Kwolek

The National Institute of Justice (NIJ) reports that the lives of more than 3,000 Law Enforcement officers have been saved since the first issue of soft body armor began in the 1970s. That’s thousands of kids who got to keep their parents thanks to this extraordinary contrivance. Have you ever wondered where all that began?

Origin Story

Stephanie Louise Kwolek was born to Polish parents in Pittsburgh, Pennsylvania, in 1923. She was one of two children. Her father was a naturalist, and her mother was a seamstress. Though she was extremely close to her father, he tragically died when she was ten.

Young Stephanie and her dad spent countless hours roaming the Pennsylvania forests. Along the way, Stephanie developed a deep and abiding love for nature. Out of that grew a passion for science. Stephanie outpaced her classmates in school and resolved at a young age to become a physician.

Then, in 1946, Stephanie graduated from Carnegie Mellon University with a BS in Chemistry. This seemed a decent path to medical school. However, she took a temporary job in a chemistry lab to make money for her medical training. While there, she met Dr. William Charch who worked at DuPont Chemical. Charch is the guy who invented waterproof cellophane.

Catching Attention

Dr. Charch was impressed with the young woman’s drive and intellect and arranged for her to interview at DuPont for a position as a chemist. She got the job but never intended to stay. Throughout her early time at DuPont, Stephanie really just wanted to use her position as a springboard into medical school.

The late 1940’s was an interesting time in America. Sixteen million American men had recently served in World War 2. One in every thirty-eight died. Many large companies struggled to fill their vacancies amidst the massive economic boom that blossomed out of the war. Stephanie’s project at DuPont involved researching radical new chemical technologies. DuPont had introduced nylon recently, and their research in exotic polymers was cutting edge.

In short order, Stephanie discovered that she actually had a very real gift for chemistry and shelved her plans for medical school. WW2 had served as an engine to expand the body of scientific knowledge at an unprecedented rate. With technology exploding in the Space Age, Kwolek found herself uniquely positioned to lead that charge. Over the course of the next four decades working at DuPont, Stephanie Kwolek made some truly earth-shaking discoveries.

A Visionary

First off, the Nylon Rope Trick is a staple of modern academic chemistry research labs. I’ve done it myself a couple of times. Stephanie Kwolek first defined it. The experiment involves combining an aliphatic diamine with a solution containing aliphatic diacid chloride that is not miscible in water. The result is a synthetic diamide that propagates as a soft film on the surface of the solution. This process is called interfacial polymerization.

Available on GunsAmerica Now

By gently grasping the film and pulling it off of the solution, the resulting Nylon 66 will form a strand that can be wrapped around a stick or similar object. As the film is removed this allows the reaction between the two reagents to propagate further, creating yet more nylon. Lastly, by gently wrapping these fibers around a stick, raw nylon can be harvested.

Kwolek’s work in the 1950s and ’60s orbited around unconventional applications for exotic synthetic materials. Most of these were aramids, short for “aromatic polyamides.” The resulting fibers, in addition to being extremely tough, could be formed into a wide variety of exotic materials.

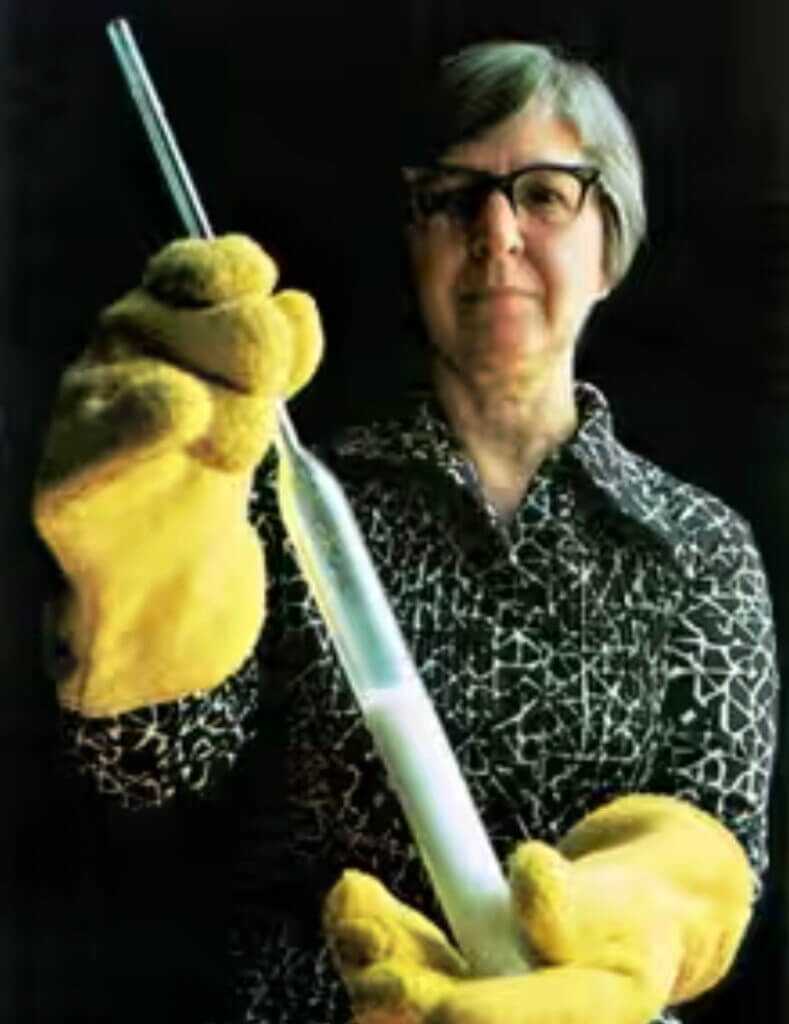

Kwolek Makes Kevlar

Kwolek’s mandate was to develop a new, tough, synthetic material that could be used in lieu of steel in reinforcing automobile tires. One of the materials she discovered was a low-viscosity, turbid, stir-opalescent liquid that looked very similar to buttermilk. This solution of poly-p-phenylene terephthalate and polybenzamide formed a liquid crystal and was typically considered a waste product.

On a whim, Kwolek persuaded Charles Smullen, the technician responsible for the spinneret machine in the DuPont lab where she worked, to let her try to extract uniform fibers from this literal garbage. Smullen, for his part, was concerned this new chemical compound would clog up his delicate machine.

Kwolek got her way and was thrilled to find that the resulting fibers were five times stronger than steel at a substantially lighter weight. She discovered that this radical new material could be made even stronger via heat treatment. Kwolek and her colleagues christened this amazing new material Kevlar.

But What Could You Actually Do With Kevlar?

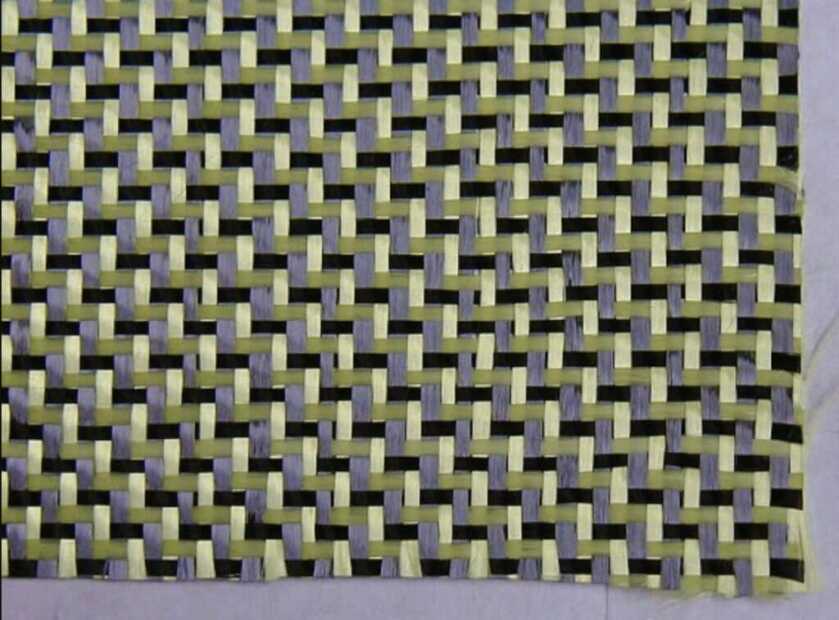

The astronomical casualty numbers that came out of World War 2 showed a desperate need for lightweight body armor that would still leave a soldier sufficiently mobile to accomplish his mission. By weaving Kevlar fibers into sheets, Kwolek found that the resulting material was durable in ways that bordered on the supernatural. Eventually, somebody tried shooting it, and the whole world moved just a little bit.

READ MORE: Biden’s Joint Speech to Congress: What do you think deer are wearing kevlar vests?

The Kevlar sheets used in bullet-resistant vests are tightly woven and must be protected from the sun. Like most synthetic polymers, Kevlar degrades in direct sunlight. Stopping bullets is a function of efficient energy dissipation. In essence, when struck by a bullet Kevlar fibers will stretch without breaking. So long as the projectile is not unduly powerful and the material is properly oriented, Kevlar did indeed reliably stop bullets, at least the handgun sort. That observation really got the juices flowing.

Ropes, cables, cell phone cases, race cars, parachute shroud lines, boats, aircraft, and space vehicles all incorporate Kevlar nowadays. The stuff is legit everywhere. By the time Kwolek died at age ninety in 2014, more than one million Kevlar vests had been produced for issue to Law Enforcement personnel.

A Vested Interest in Survival…

Modern soft body armor is divided into several frankly confusing categories. Level IIA and IIIA are expected to stop most handgun rounds such as 9mm Para, .357 Magnum, and .44 Magnum. In the case of the larger calibers, the bullet will not penetrate, but the violence implicit in surviving such a hit can still cause soft tissue injury.

READ MORE: Eberlestock Bulletproof Backpack

Level III and IV body armor is rated to stop large-bore, high-velocity projectiles from long guns. As the degree of protection increases, however, the vests typically get heavier and bulkier. When the threat simply becomes too threatening, most soldiers in the Armies of advanced nations as well as tactical teams will use plate armor that is made from either alloyed steel or advanced ceramic materials. Plate armor will reliably stop all but the nastiest armor-piercing rifle rounds.

The Rest of the Kevlar Story

At the time of her death, Stephanie Kwolek held 28 patents. In addition to Kevlar, she was also instrumental in the development of both Nomex and Spandex. In so doing, Kwolek likely did more to extinguish flaming aviators and support sagging body parts than any scientist before or since. Kwolek’s exotic new materials have become commonplace around the globe.

Because she worked for DuPont, Kwolek relinquished the rights to materials discovered on company time to her employer. As a result, despite the fact that the resulting monetization of her ideas brought in literally billions of dollars, Kwolek herself benefitted minimally from her groundbreaking discoveries. According to Google, her net worth was around $5 million at the time of her death.

Things End Well For Kwolek

Despite her relatively modest financial success, Kwolek was honored with a wide variety of personal and professional awards. She was ultimately granted a further three honorary degrees as well. By all accounts, she led an exceptionally satisfying life. Here are a few quotes—

“I guess that’s just the life of an inventor: what people do with your ideas takes you totally by surprise.”

“I hope I’m saving lives. There are very few people in their careers that have the opportunity to do something to benefit mankind.”

“Not long ago, I got to meet some troopers whose lives had been saved. They came with their wives, their children, and their parents. It was a very moving occasion.”

The extraordinary female inventor Stephanie Kwolek clearly found ample satisfaction with her life’s work. Whether it was flame-retardant clothing for military aviators, bullet-resistant vests that have ultimately saved countless cops, or push-up brassieres and bikini swimsuits, Kwolek’s inventions have legitimately changed the world. It was obviously a pretty great thing that she never followed through on her plans for medical school.

*** Buy and Sell on GunsAmerica! ***

Thank you for educating me, Will. I’ve worn both Kevlar and Nomex during my days with Uncle, and can personally attest to the fact that both fabrics do not “breathe” and are thus a pain in warm temps. Thank God I never had to function test either material.

I’ve also spent a great deal of time examining spandex. Perhaps it should be used in radial tires… it certainly hugs curves extremely well. Props to you for your pictorial representation of spandex. That example is… well… exemplary indeed!

Another unsung hero behind the scenes. Truly a Nobel peace prize oversight. Great article

My grandfather was employed by Harley-Davidson when he invented the kickstand, so he put it in the public domain. He died in 1986, virtually penniless, so I’d say she did well being worth 5M in 2014. Corporations owning rights to inventions is the norm particularly when developed on company time or with use of company materials.

Being a retired LEO, I enjoyed reading this article. I worked for many years before Departments began issuing vests. Buying your own was an extremely expensive endeavor and difficult to afford on a police officer’s salary. Most Departments fought against them because they didn’t want to spend the money to purchase them.

However, I somehow remember learning that Richard Davis of the Second Chance Company, is credited with the development and eventual use of soft body armor. He was relentless in marketing his vests in trying to convince Department’s to purchase them. He would even shoot himself in the chest with a .44 magmun, while wearing one as a demonstration, to convince the Chiefs and Sheriffs to buy them.

ALL of Law Enforcement is indebted to him.

Thank You

Great story…as usual. Thanks Doc.