For more information, visit LeeArmory.com.

The guys at Lee Armory know AKs. They run a manufacturing operation and have all the jigs, fittings and parts for building AK-pattern rifles. They also have a cadre of gunsmiths who know and love the Kalashnikov design in all of its variants. Put all this together and you get a company that has seen every AK problem with the hardware and know-how to fix it.

All AK parts are not created equal. Lee Armory has a complete stock of quality forged virgin parts from a Romanian factory. They even have Romanian cold-hammer forged barrels with no gas ports. With no pins and no holes, these parts can become the exact custom cut part you need.

I got to spend time with the gunsmiths from Lee Armory at their shop in Phoenix. I took their AK build class and shot several of their AKs. Their work speaks for itself, the guns look great and run even better.

Because I was driving out to Red Oktober, I had a couple of extra AKs in the car. I knew Lee Armory did repairs, so I took my problem child. I have seen and shot AKs from all around the world. There are some amazing variants and enough models to give most shooters a dream gun. I am partial to full-stock classic models because I feel they shoot better. I used to think that all AKs were reliable. Turns out that even the best designs can be built poorly.

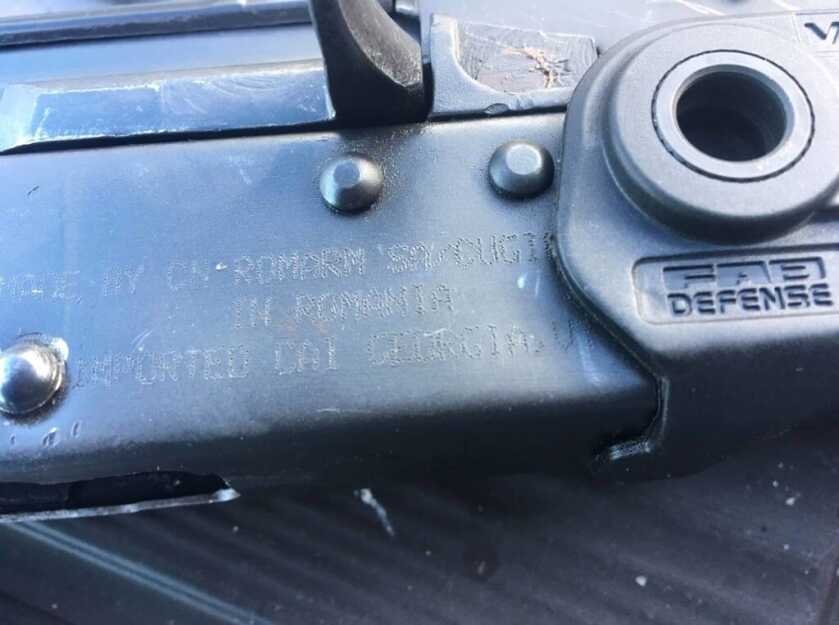

I once got a WASR Romanian AK as part of a trade. It looked crude, but I figured, how bad could it be? It passed a function check and the provided magazine fit, what could go wrong? It turns out, even with good parts, an AK can be poorly assembled. Once I got around to an AK range trip, here is what I found:

My Problem Gun:

- Magazine well was miss cut and would not accept most AK magazines

- Trigger slap

- Poor accuracy with several brands of ammunition

- Frequent jamming, mostly failure to chamber and double feeding

- Loose rivets

I grew to hate this gun. Like many other owners, I didn’t write off my poor choice as a loss, I doubled down and decided to save this poor girl no matter what it took. Lucky for me, none of the issues were fatal and I had some expert help. Josh at Lee Armory invited me to bring the WASR into the shop. He was confident they could fix my gun during the build class. He was right! There was nothing he had not seen many times before. It seems that a lot of people buy cheap AKs. There is a reason they are cheap.

The AK-47s I saw on battlefields around the world were made on quality tooling and jigs. The development and production costs were borne by a Cold War economy which lavished resources on the military.

Like many people, the design and manufacture for sheet metal guns like the MP-44 and the AK fascinate me. The simple and robust technology used in the AK has many subtle features, not the least of which is the ability to fabricate the rifle under austere conditions for wartime production. They are designed by geniuses to be made and operated by illiterate peasants. They were assembled by unskilled labor working with quality machinery under the supervision of quality assurance comrades who maintained the needed standards. Good enough was what they strived for. What I learned in the infantry when studying the Russian war philosophy, “Quantity has a Quality all its own.”

SEE ALSO: Krebs Custom Announces 9x39mm AK Pistols and Ammo Incoming

When these robust AKs get cut up into parts kits or are reproduced for civilian use, most of the time the factory fixtures are not used and the quality-control comrades are now unemployed drinking vodka. The riveted sheet metal design of the AK is brilliant, but it must be assembled properly to work. The over-strength engineering will tolerate gross abuse but poorly made parts and improper assembly will bring it to its knees. Most people never shoot enough to see an AK break.

Head spacing encompasses one of the most important tasks for the rifle to function safely. Most home builders don’t understand the risks of incorrect head spacing. The AK design is very forgiving, proper headspace is essential. Additionally, the critical fit of parts like the gas tube and magazine catch can ruin the reliability of a gun.

Building an AK-pattern rifle includes the handcrafted art of rivet smashing. Rivets are much easier to make than screws but it’s not as simple as it seems. To get the full strength a rivet can provide, you must have the correct rivet profile and smash it with the proper tool. If the metal doesn’t flow properly, it will not join the trunnion to the receiver as it should, weakening the gun and possibly misaligning cycling parts.

Lee Armory has the tools and gauges needed to do things safely and easily. They offer technical advice and support.

Lee Armory’s AK Fixes:

- Adjusted trigger

- Checked head space

- Tuned dust cover to eliminate bolt drag

- Replaced rivet

- Replaced mag catch pin and adjusted mag catch

- Replaced stock added FAB Defense M-Lok handguards and Tango Down grip

Josh and Mario at Lee Armory did all of this in about 30 minutes. I was fortunate the CNC machine was already set up for the magazine well cut. They looked at my gun, shook their heads and went through my problems, part by part. When they were done, we gauged the head space and test fired into a bullet trap in the shop, so far so good. The next step impressed me.

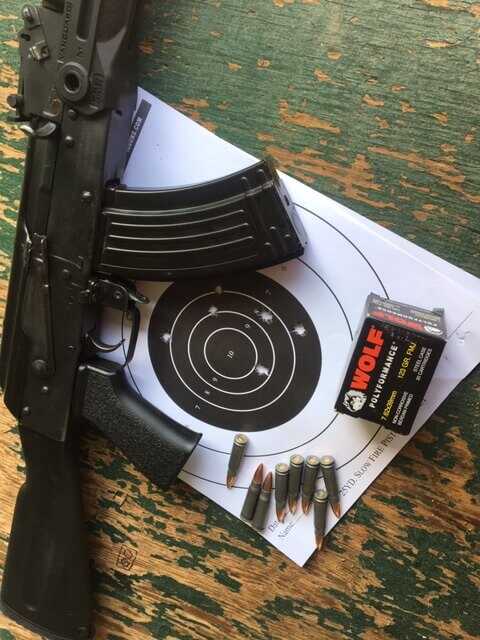

Mario loaded my guns into a car and we went to a nearby range. We pulled up to a bay with steel target at 200 yards. There were several size plates ranging from 36 inches to 12 inches. No paper, nothing closer than 200 yards. He had my attention.

I shoot two rounds from the bench at the big gong. Both misses. Mario looks at the desert dust clouds from my shots and makes one windage adjustment and one elevation adjustment. My next shot hits the 36 inch plate, then I hit the 24 inch plate. With no confidence at all, I then hit the 12 inch plate. My next shot missed, but that was me. I put the next three rounds on the 12-inch plate. Considering the ammunition I was shooting only holds, roughly, an 8-inch group at that range, this gun was shooting very well.

I thought that was lucky. Mario zeros each Lee Armory gun before it ships, he is good at it. We then pulled out the Lee Armory’s Romanian Military Classic AKM I had just made in the build class that day. Same story, look at the dust cloud, one windage adjustment, one elevation adjustment, hit steel. I have seen a lot of AKs zeroed. I have never seen anything like Mario’s feel for the sight tool.

I left Lee Armory that day and drove to Henderson, Nevada for the Red Oktober AK event. My buddies at KCI USA needed an extra rifle for their demonstrations. I loaned them my former problem WASR. They put almost 500 round through it over two days, mostly mag dumps to show the reliability of their magazines. Using KCI USA magazines with Wolf and Red Army Standard Ammunition there were no malfunctions.

You can send you gun to Lee Armory or bring it by the shop. They are always busy, but find the time to give great customer service. They can build you a gun, help you build a gun in build class with your parts or theirs. And they can fix your broken AK.

For more information, visit LeeArmory.com.

I never met Josh before I pulled up to the back of Lee Armories building, explained my neet to replace one lower front handguard retainer and that even Arsenal was sold out…I had scoured Phoenix to no score…Josh drops one in my hand,won’t take a dime for it, and was super cool listening to my rant and need. Good article Sir. Thanks again Josh!

Josh from Lee armory saved my butt and really helped me out wile saving me money and going way out of his way to help me install headspace and pin my barrel. The best customer service I probably ever experienced.

Good write up. Lee Armory sounds impressive and there’s ALWAYS room for more experienced ‘smiths in the AK world. I too ‘had’ (?) a problem-child AK. I have worked on it myself which consisted mostly of a canted front sight, NOT holding zero and THE biggy: Realizing the trunnion (primary/front) WAS ALSO CANTED…just enough to make me realize I couldn’t “straighten” or do anything with my rear irons. Kept asking myself “HOW did I miss this!? (when I looked it over initially?). The concept of inexpensive CAN be construed to also mean “cheap”. OR poorly built, as so well mentioned in the article. This AK was destined to be a ‘beater’/ range rifle from the start and that cemented the fact. I’ve also had to replace the spring guide with one I KNEW was quality (Bulgarian) as the bolt kept literally ‘jumping’ the rails consistently. That made all the difference. I’ve been able to fix everything BUT the MAIN thing…the trunnion. Yeah, THE most important part of the AK where it all starts and determines the integrity of the rifle. It’s actually a “decent” shooter, now, in the sense of not having any feeding, failure-to-fire or FTE’s, etc. The front sight pin just needed to ‘spread’ and re-zeroed. I do see it for what it is…a low-end AKM that’s allowed me to gain a bit of knowledge on the platform, but I am glad my go-to is NOTHING like this one…

Crooked sights make me crazy. There is a fix, depopulate the barrel, get a new barrel and reinstall the trunnion and front sight, but do it straight this time. That probably doesn’t help your situation.

Get an arsenal or vepr

Problem fixed

The universe of working AKs is far grander than two companies. Even great guns can have problems and it is nice to know who can help.

Really enjoyed the article. I might need to contact these guys as I too have a problem child

There is something very satisfying about making a gun work properly.