OSS began with a radical idea and an equally radical suppressor system. Compared to baffle stack suppressors, the original OSS suppressors looked different and were sort of hard to understand. In the past couple of years OSS has simplified their design and introduced new models. For SHOT 2019, OSS released two new suppressors, the HX-QD 338 Ti and the HX-QD 762MG.

The new HX-QD 338 Ti weighs only 23.4 ounces despite its 9.1-inch length and 1.75-inch diameter. It was specifically designed for the .338 Lapua cartridge, and the company says it will deliver 134 to 138 dB performance at the shooter’s ear on a 26-inch barrel Lapua bolt action rifle using 285 grain or higher bullets. OSS had such a rifle at the SHOT Show Industry Day at the Range and it was a delight to shoot. This suppressor is made from Grade 5 titanium and heat treated 17-4 stainless steel. It is available now and has an MSRP of $1,599.

The HX-QD 762MG is a completely different animal built for a completely different purpose. It weighs 28.7 ounces and is only 8.25-inches long. It was designed to meet a military requirement to suppress belt-fed machine guns. Because of the low back pressure design of OSS suppressors – they call it Flow-Through Technology – this application was a good fit. Baffle stack suppressors usually create enough back pressure that the reliability and durability of machine guns is negatively affected. The OSS design doesn’t have that problem. The HX-QD 762MG is available now in limited quantities and has an MSRP of $1,849.

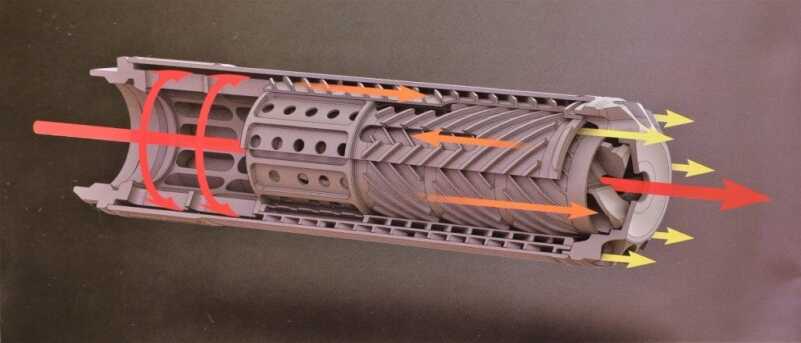

OSS has what is probably the most unique gas management system in the world of suppressors. Rather than a baffle stack, gasses are routed forward, backwards, and again forward of the shooter – all in a helical pattern. OSS contends that this design creates a suppressor that has minimal back pressure, a claim that stands up to testing. The usual reaction to someone shooting an OSS suppressor for the first time is a smile and then a question about the adjustable gas block. No such accessories are required with OSS suppressors – standard gas blocks work just fine.

For more information on OSS suppressors visit: OSSSuppressors.com.

OSS builds suppressors to exacting standards, such as for candidates in the US Army M110A1 CSASS/SDMR Rifle.

I like the idea of the technology involved…. it’s nice to see innovation in suppression. When the price and the noise level comes down I’m definitely getting one. I don’t get gas in my face from my rifle suppressors, even on my sbrs, bolt action rifles don’t need gas blocks and the only time I use gas blocks is on short to medium length full auto suppressed rifles.

There is something wrong when a suppressor cost as much as or more than the firearm it is intended for. The cost to manufacturer can’t be more involved than it was to fabricate and assemble the firearm.

What gives?

I am sure ‘someone’ is going to complain about the weight. And others about the maintenance nightmare this could be. All valid points. The huge upside to this model – it will have little or no FRP (First Round Pop)………. and all of the gases are ‘processed’ in the suppressor – when the gasses finally exit they are not going to give the big @ss thermal signature a regular baffle model would. This model is not optimized for long afternoons at the range – its a one shot and slink away model.

Belt feds are not normally one shot and slink,lol

I’d like this on a sbr krink.quiet powerful and handy.

Why in the world would someone buy a 29oz suppressor with all the great silencer that suppress better and weight half as much . I’ll take a Little back pressure thx

Maybe that last line… “Standard gas blocks work just fine”. Not everyone has working knowledge of adjustable gas blocks.

Also having no back pressure is an innovation that will mitigate wear and tear on the action. Especially automatics. It also means you’re less likely to get blasted in the face with hot gasses on AR platforms, so it’s safer for the shooter.