If you’ve never played with reloading, it can be a challenge. The set up of a good press is the perfect way to spend a Saturday inside. Here, we’re working with a Hornady Lock-N-Load AP. I’d clamped it to the kitchen table while we were setting it up. Bad idea. Turns out the wife wasn’t thrilled with the new addition to the kitchen.

We’ve been thinking a lot about bad weather recently, and what you can do to occupy your time. Reloading may seem daunting to some, and for good reason. It shouldn’t–there are clear cut manuals that will walk you through all of the measurements that, if ignored, make reloading dangerous. And there’s no better way to blow through an afternoon than producing a great big pile of ammo you can shoot when the clouds clear.

I’m brand new to the reloading game. I’ve been saving brass for a long time, and during the great ammo recession of 2013, I was actively scouting brass and primers for friends and acquaintances. I was striking deals with FFLs and shop managers that put Colombian cartels to shame, trafficking brass and large pistol primers in quantity. But while I was a master at sourcing components (and never once ran dry), I never assembled the ammunition myself, and I called in a lot of favors.

Yet there comes a time in everyone’s life when they have to get off the sidelines and into the game. I shoot, on average, 1,000 rounds a week. There are times when this is lower, and sometimes I will run 1,000 in a long weekend, but I shoot a lot. I’m not relegated to one caliber, either, so I wanted a reloading setup that would allow me to switch between calibers easily. The Hornady Lock-N-Load AP seemed a logical place to start. It is a cast aluminum, auto indexing press with five stages.

I thought I would unbox this thing and be on the range with a mess of .45 ACP that afternoon. Nope. Set-up is serious business. I’ve discovered that there are several learning curves one has to get over on the way to functional ammo. And the first one you’ll find with the Lock-N-Load is the set up of the progressive stations.

Each of the caliber-specific components locks into the press in a modular fashion. If you want to set up the whole press for .45 ACP, reload a batch, then move to .308, you don’t have to scrap the settings for your .45 ACP. Just removes those components and set up for .308. Once your set-up for each caliber is complete, changing them over is incredibly fast.

How long does set-up take?

Well–how many licks does it take to get to the center of a Tootsie-Pop? The world may never know. Actually, I’d say it depends on your skill set. From the time we opened the box until we got our first functioning .45 ACP reload was about 4 hours, give or take. And there were two of us monkeys working on it.

[full_width]

[/full_width]

After several attempts, we got the .45 ACP components cooperating nicely. We’re .004 of an inch off of our target mark.

We ran some test brass, then ran some more. We would get the primers set, then move on, sequentially, station by station, until we had everything right. In between, we would pull the brass and check specs, and try it all again. This station does everything except clean the brass, so there’s a lot to get right. We loaded brass by hand, and then the press de-primed, primed, sized, added powder and capped it off with a bullet. Pull the arm like you would on a slot machine and the press makes half a rotation. Let it go and it completes the movement.

Hornady says the press can produce 500 rounds in an hour. That’s faster than I usually shoot them, so I’m all in. I’m not there yet. In fact, I haven’t tested the first rounds. But I’ll get there.

In the meantime. Anyone out there proficient with the Hornady Lock-N-Load? If so, what was your experience with initial set up times? And does it get faster as you learn the proverbial ropes? Share your experiences below….

[one_half]

The lock and load part of the Lock-N-Load is easy to understand. The dies twist in and lock into the press.

[/one_half][one_half_last]

These die bushings allow you to set up modular components for various calibers, or even different bullet shapes.

[/one_half_last]

[one_half]

Because this press has tight spaces with limited access, some photos aren’t as clear as I’d hope. But, we figured it out. And YouTube has a wealth of extra help. If that’s not enough, there’s a DVD included.

[/one_half][one_half_last]

Be sure your work space is clear and easy to organize. And ask your wife if she minds you clamping it to the table. Odds are she does. Seriously, though, don’t do what we did–set it up where it needs to be. And bolt that sucker down.

[/one_half_last]

[one_half]

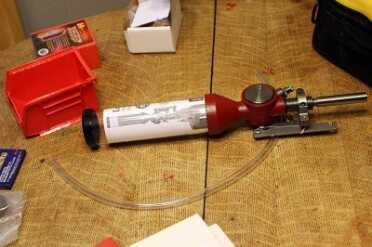

The powder dispenser may be the most daunting part. This is, after all, the one thing you shouldn’t screw up.

[/one_half]

I recently purchased a Hornady L-N-L Progressive Press after comparing its performance to other major brands. I concluded that the L-N-L’s price point, coupled with the testimonials from satisfied customers and Hornady’s reputation for producing quality products, made it a “best buy”. So far I have loaded about 1500 rounds of 9mm and .45 ACP. I expected to have some start-up issues, but am disappointed that some of these have continued. These include timing to align the shell plate which requires periodic readjustment of the left side pawl and primers hanging up in the feed tube and assembly that moves the primers into position for insertion into the case. When this occurs, the priming system must be disassembled to access and clear the jammed primers. This is aggravating and disassembling the priming system usually results in primers spilt on the workbench and floor. While not a problem with the L-N-L press per se, there is a problem with .45 ACP in that some manufacturers, not all, use small pistol primers. When reloading pre-fired brass, you should examine each case to ensure that the press is set to insert the correct primer. All in all, the jury is still out on my satisfaction with the Hornady L-N-L progressive press. I am continuing to learn about its “care and feeding” and am optimistic that once the bugs are worked out, the press will be a joy to use.

Take your time and set up each thing separately. Watch the DVD over a few times and have it in the shop with you and just do what the guy does step by step. Read the manuals take each part apart and get familiar with the functioning of each individuale component. Before you even think about powder get the resizing, priming and expander dies as well as the seating/crimping die all set first. Do some practice loads with no powder to make sure you have proper seating and length. Then do some loads of powder and make sure you’re getting consistent powder charges. Check everything and check it again. You can never check it too much. People who have problems are anxious and impatient. It’s the ultimate tinker toy. If you don’t like tinkering don’t bother. If you enjoy taking a pistol apart and putting it back together you’ll enjoy this.

Very interesting and helpful info…especially the letters

I have a Hornday AP and love it. Once it’s setup correctly, it works reliably and is easy to reconfigure to a different caliber. There are a few minor things that can be done to improve the press that are described on utube by Bill Morgan. View his videos and pay attention to his recommendations.

I started reloading with a single-stage press. This works well but is very slow. I recommend starting there however because reloading is a bit of an art and requires a good understanding of what your are doing. A single stage press lets you focus on one operation at a time until you get it right. Once you get skilled with the basics, transitioning to a multi-stage press is easier.

As long as everything is setup correctly, I can turn out quality ammo at a good pace. Things get screwed up when something goes wrong. The most common problem is a failure to seat a primer deep enough or seat at all. My brass comes from the floor of the range and gets mixed headstamps. Sorting the headstamps helps but takes time. Since you can’t clean the primer pocket after removing the primer, a bit of crud in the hole can make seating the primer unreliable. I think you’ll have this issue on any press.

Some powders in some shells can spill a few flakes of powder over the case mouth. This happens because the shell gets wiggled when the press rotates the shells. Powder can get under the shell plate and find its way to the primer feeder. If enough gets there, it can prevent the primer feeder from positioning properly and cause a primer to fail to seat. Using low volume powders such as titegroup helps since they sit lower in the case. A can of spray air shot under the shell plate every now and then blows out the flakes and helps too.

I never produced any 500 rounds in an hour. I might run 200 in an hour if everything goes well. Changeover to a different caliber takes about 15 minutes. Most of that time is readjusting the powder dispenser. Swapping dies takes less than a minute. The rest of the time is spent double-checking the setup and measuring the first few rounds for correct size.

I’ve loaded thousands of 45 and 9mm with my LNL. I am not mechanically inclined, but I can read directions and consult the internet and my LNL hums right along. Dillons are fine machines as well, but for what I do and my experience, the 650 would be a comparable machine. I did have a 1050 Dillon and it was way to complicated for me to maintain and switch out between calibers. I sold it and got the LNL and haven’t looked back. Really, if you can’t set up and run the LNL, you probably shouldn’t reload, at least not on a progressive loader.

I have been using the LnL press for about six or seven months now, I started out doing pistol (.45, 9mm, and .40s&w) initial set up took a while and being brand new to reloading I took extra time to make sure I was doing everything right. The biggest help was YouTube, there are some very helpful if not self embellished videos that walk through setups and also helpful tips. Bottom line, as a beginner I picked it up pretty quick. Several thousand rounds later I can say that I really like the LnL press for all my pistol needs. Just to be clear I don’t shoot match just range plinking and self defense practice. Now all that being said here is where I have run into issues. This fall I started loading rifle ammo. For the most part this press fails on an epic level for rifle loads. The powder throw is horrible with any but the fine or spherical powders so getting consistent powder charges is out of the question. I’m not sure if it’s the press or the dies, (I think the press my self), but I cannot get it to resize the brass so that it will pass a go /nogo gauge on headspace. Using RCBS dies in the press I can achieve about 80 percent pass rate, which is still unacceptable in my opinion. I could go on with the faults in the rifle reloading department but why. Just know that if your focus is on pistol reloads you should be just fine but if you are looking to load more than a dozen rifle rounds don’t bother frustrating yourself, just get a decent single stage it will be faster.

A note on the 500 rands an hour. I can load about 350 if I get in a good cadence but truthfully it is easy to make a mistake, I usually average about 200-250 with no bad rounds and random inspections to double check tolerances, and thats plenty for me. Good luck and happy loading.

What was wrong with the round in the third picture from the top with the seated bullet on the left? It didn’t look obviously bad like the overcrimped/overbelled rounds on its right…

I am 73 years old, been reloading for 46 years. Started with RCBS Rockchucker, then Dillon 450, Dillon 550, then sold all my Dillon to buy a Hornady Lock-N-Load and added auto case and bullet feeders. Dillon makes rock solid presses and no one beats Mike Dillon’s no BS warranty, he makes good stuff and backs it up! Hornady studied the competition, saw it’s short-comings and made improvements that beats the competition hands down. I love my L-N-L, it changes calibers quickly, sets up easily and is capable of fast production. That said, if speed and mass production is what you want buy a commercial press ($2K and up) and stop bad-mouthing everything else! In my opinion anyone that has problems with the L-N-L press should not be reloading as they do not have the skills or mindset to do it……reloading is SERIOUS business and requires education and patience.

OH…Come on Jerry!

Tell us how you REALLY feel.

(Laugh!!)

I have been using the Hornaday progressive press since it first came out 30 some years ago. Later when I could not get pawls for it anymore I bought the new lock n load press. The only problem I had with the new lock N load was the primer feed. I called Hornady and they told me to make sure the primer bar went a little past the dead center position under the primer tube. This cured the problem but it should have been stated in the manual. I like the lock n load because I can twist out individual dies if I need to clean them. I cannot do this with a Dillion tray type holder that holds all the dies. I have had no problems with the Hornady powder measure it is a good one and one can buy extra feed screws that you pre-set to throw different powder charges. The lock n load has grease fittings that the original Hornady press did not have. Few people know that the original designed Hornady progressive was actually bought from Dillion. I don’t think Dillion ever marketed it. With the powder measure I had problems with it coming loose by twisting in the lock n load die so I added an extra “o” ring from a Remington 1100 Shotgun. You can get the same “O” ring at the hardware store, if I remember it was a number 33. With the original “O” ring and the extra “O” ring it cured the problem of the powder measure twisting and coming out of the lock n load die. I also use a straightened coat hanger to put pressure on the primers instead of the wooden one Hornady sent me because the steel coat hanger wire is heavier. It pushed down on the primers as they move down through the primer tube. I would also suggest you grease the heck out of the pawls because if you do not they will eventually wear out but the original Hornady progressive press lasted me about 30 years so that was pretty good service life for the pawls. I think too that everyone should also have a single stage press as well and a spare set of dies to put into the single press because if you mess up when using the progressive you can take the messed up round and fix it using the single stage press rather than trying to fix the messed up case in the progressive. I think too that a single stag press is necessary for the beginner until he thoroughly learns how to hand load ammo then he can move up to a progressive. I never load full size rifle cases on any progressive because the cases need to be trimmed after they are sized which defeats the idea of using a progressive press to load them. Priming on progressive presses often is weaker than using a single stage as well so this is another reason I do not hand load rifle cases on a progressive press and have a need to prime rifle cases on a single stage press.

I switched the wooden stick they sent me as well, but I use a piece of brass brazing rod instead of the coat hanger. Simply because most of them are made from steel, and k am not a fan of anything that can spark on the primers. 😉

The brass rod seems to be a tad heaver as well..And matches the tube opening almost exactly if you buy the right size.

Just a suggestion is all guys. I may just be paranoid.

(But I have not had a “accident” in reloading in over 40 years now, since I started. So maybe paranoid is a Good Thing in this hobby..??)

People must not be reading their manuals or taking their time setting up each stage because I’ve reloaded over 10,000 rounds with my press and haven’t had any major problems other than wear and tear. As far as the wear and tear, Hornady quickly sent me replacement parts free of charge, all I had to do was return the worn part for inspection. The quick change bushing set-up is awesome for anyone who loads numerous types of ammo. Don’t get me wrong, my friend uses the Dillon progressive press and there are things I like better than my Hornady progressive press but there are things he likes better about mine over his too!

A new person to reloading should start out with a single stage press, use that for at least a year and then think about a brand other then Hornady lock and load. I have a RCBS and Dillion progressive presses and they both work well.

The Hornady a friend has can not be made to work, poor design.

Mike Circle

I am 74 years old, and been reloading for 50 some years. my press’s include Dillon 550, RCBS 2000 and a lock and load. IF you read the instructions the Lock and load sets up easy and fast to use. It’s as good as any other press.

If you want a lot of ammo, really fast…hop in your car and go to WallyWorld. Otherwise send your Frau und Kinder to the mall, turn off the radio/tv, and pay strict attention to the loading process.

Multi-stage presses are about convenience…NOT speed!!!

I’m 70 and have been loading since was I was 17, and have NEVER had a bad round…single stage, hand press, multistage, motor-driven. NEVER!

Carefully adjust your dies, check primer seating depth, check the powder charge, (get a Powder Cop from Hornady for your progressive), check bullet crimp and O.A. length. Some of these can be after the round is assembled, and some are during the loading process. Go slow, double check each function. After the auto powder feed, take a flashlight and look in each case before the bullet is seated. DON’T get in a hurry…do so at your own peril…or a loved one’s.

Worried about a few of your rounds??? If you are worried about the quality of your ammo…you’ve got no business loading in the first place.

Well said! I have the Hornady Lock N Load AP Press. I took my time setting it up which included the necessary cleaning of the components BEFORE you begin reloading. I checked and re-checked my dies and powder measure and once I had everything calibrated, I loaded my first round. I checked the OCL, primer depth and crimp and then produced 4 more rounds before re-checking the OCL and power charge with my electronic scale. I then produced 10-rounds. I re-checked my OCL and charge and went on to produce 25 rounds total for my first reloading session. I took the rounds outside and test fired them without incident. I am now producing rounds in 5 different calibers and really appreciate the quick change die bushings.

I don’t understand all the negative reviews of this press. If you follow the instructions and take your time calibrating it, it works great. If you are someone who wants to sit down and crank out hundreds of rounds without making minor adjustments from time to time, then you will be frustrated. This is a hobby of precision. Like someone else said, if you want hundreds of rounds right now, go to Wallyworld and buy them.

One other comment. I have had nothing but the best customer service from Hornady. When I damaged a component on one of my new dies, I called to order a replacement part and they said, “Don’t worry about it, we will send you a new one.” which they did free of charge. Every time that I have called them with a question about a part or order, they are polite, helpful and very efficient. Refreshing that a company actually cares about its customers.

I love my lock n load. Once I have it set up for the round I’m loading I don’t have to touch it again. I like the 5 stations, because it allows me to have a lock out die for the powder measure. I really don’t understand why anyone would have problems setting it up. I’m keeping my L’n L. Thanks Hornady!

Gosh, I’ve been using a Star Press for 45 years and haven’t had any problems with it yet

This reloader is pretty poor. I was lured in by the promise of 500 free bullets, which should have told me something!

The system works off a ‘rubber band’ made of a spring steel material which does a lot of slipping. The powder measure is worthless & was soon abandoned. Their bushing design, meant to allow you to adjust the dies only once, simply doesn’t work!

The folks at Hornady Customer Service don’t seem to know much more about the system than I do and apparently feel like they’re doing me a great favor, merely by answering the phone!

In short, I use my old RCBS Rockchucker manual press far more often than I should have to.

I had only two problems setting up the complete press, including the electronic monitoring/display unit. The Hornady wrench is virtually useless as it doesn’t fit onto the die nuts once screwed into the press, and there was no easy place to mount the display of you don’t have the auto case or bullet feeders…little improvising was necessary. 10,000 rounds later, the complete unit is still doing what it’s supposed to do. Cheers.

DILLON IS HE ONLY WAY TO GO FOR A PROGRESSIVE LOADING PRESS. THE OTHERS JUST DO NOT MEASUR UP. AND DILLON HAS A LIFE TIME WARRANTY.

I use a old C-H press 4 stage. Has been in use for 35 years. Never fails 250 .243 .308 .5.56 per hour. 450 straight walled rounds per hour

I like the powder system on this press…that’s all though. It uses some very odd methods to do the job. There’s a spring that goes around the shell holder plate which holds the shells in the plate…which doesn’t work very well. The lock-n-load system does not work well. The fitting the dies are put in is round…as in “you can’t use a wrench to remove the dies from the press” since there’s nothing to grip. a very poor design. I much prefer my Dillon press.

I ended up tossing my Hornady Lock-N-Load AP press. I spent hours on the phone talking to Hornady tech support trying to get it working right. No mater how much I fussed with its settings, I could never trust it to make consistently safe ammo. I replaced it with an RCBS Pro2000 Progressive Press. I could never get it working right either. Dillon is the only way to go if one wants/needs a progressive press.

Ditto. I had the same problems with my LNL. I purchased a Dillon 650 and never dreamed how pleasant and rewarding reloading could be!!