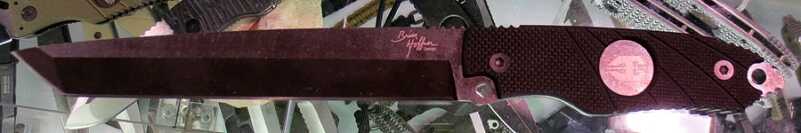

There are knives, and then there are KNIVES! Brian Hoffner’s “Beast,” a radically rugged tanto-tipped fixed blade, falls into that latter category.

With a 5/16” full-tang spine, the Beast is more railroad spike than knife, arguably. Actually, a better description might be a crowbar with a sharpened edge. It’s thick as hell, strong as hell and sharp as hell.

Hoffner, a 34-year-veteran police officer and anti-terror expert, specifically designed the Beast for first responders, police officers, military operatives, basically, anyone who would need a purportedly “indestructible” tool in the field.

As Hoffner likes to say, “I built an indestructible carry tool that will cut, penetrate, pry, hammer, chop, trench, baton, break, rake, smash, slash, crash, and trash all in its path.”

Features:

- Full Tang 440C Stainless Steel Drop Point Tanto Blade

- Ergonomic G10 “Grippy” handles with Index Divots.

- Multiple use, easy to carry, heavy duty tool. Includes Kydex Sheath with ambidextrous belt mount.

- Multiple mount options: molle, in the waistband, mounts to American Tactical Apparel secret carry holster.

Specs:

- Blade length: 7″

- Blade width: 5/16”

- Overall length: 11 7/8″

- Weight of Knife: 17.6 oz

- Weight of Sheath: 3.75 oz

- MSRP: $119

Due to the weight of the Beast and its accompanying sheath — it’s over a pound! — it may not be the optimal every day carry blade to put on your person. That said, it appears to be a great truck knife or pack knife or keep-in-convenient-place-at-home knife.

There are options to customize it as well. You can upgrade from a flatline grip to a chiseled grip (for $20 extra), select your handle color (Black, Olive, Khaki) and blade color (silver or black), add custom screws ($16 extra), choose sheath color (Black, Olive, Khaki), add optional handle art ($6 extra), and lastly, purchase a lanyard ($16 extra).

Check out the Hoffner website for more details.

On a side note, Hoffner also makes some wicked 1911, G-10 grips and very cool apparel, via American Tactical Apparel. So, check those out as well.

As has been previously said, there are two gripes with this otherwise interesting knife. One is the choice of steel, 440C or any type of stainless seems like it’d be too brittle for pry-work. The second is the lack of a small, bottom-positioned single guard to keep one’s hand from slipping on a hard stab. Other than that it looks great.

I have 3 words for You…..Cee Ef Kay…..AKA, CFK Cutlery. D2 Steel… Best fixed blade knives being manufactured today at prices ANYBODY can afford. Ever tried to actually sharpen a Tanto Blade? They might look cool, but functionally they are a bust.

As someone who has been selling custom and production knives since 1985 I can categorically say that most Stainless Steel is the WORST steel for a knife blade especially 440C, It dulls easily and is hard to sharpen and stay sharp. ATS-34 and it cousins is the BEST knife steel I have owned yet and is what I carry exclusively, I even have a Titanium Blade knife (very expensive) made for the Spec-Ops folks that is better than 440C is every aspect except being able to get that razor sharp edge by hand 😉

STAINLESS SUCKS 😉

Tommy Barrios, you were wise to say “most” stainless steels are the worst steel for knife blades. However, Crucible Metal Specialties supplies their S90CM, (formerly called 154CM), to the knife makers who dare to use it. I’ll say it right now, there is no other knife steel that will hold a sharp edge, and cut like S90CM, with identical use.

However, knives constructed with this metal should never be used as a pry bar, because it is usually hardened to a Rockwell hardness of 62. Some references state that this metal is easy to sharpen. Don’t believe it! A hard S90CM blade will laugh at any sharpening material except sharpeners made of ceramic or diamond.

If one wants a pry bar, one should get a pry bar, not a knife.

It looks like a great knife. Seems a little expensive to me. I recently bought a SCHRADE SCHF 9 DROP POINT KNIFE under $50.00. A full tang blade that is 1/4” wide, talk about overbuilt. comes with a nylon Sheath with extra pouch for sharpener or other accessories. Looks great.

Just a note. In many States it is illegal to carry a sheath knife. At any blade length.. a two inch punch knife., or seven inch tanto.., if it is in a sheath – it’s illegal. Washington State is one of those.

The citizens of those states need to get some spine and remind their asinine politicians that we have the 2nd Amendment that covers carrying knives for protection, also is a protected right!

You need to relocate…

TN recently made any knife legal, whether open or concealed carry. And I am grateful.

Gravity knives, AO knives, stilettos, machetes, etc.

440 stainless is the deal breaker for me. Never did care for it; try D2 and you’ll have my interest. Yes, I know, a bit more costly and it will eventually rust, but so what? A man is supposed to take care of his equipment . . .

Norm,

Don’t confuse 440C, with 440A (not saying you are, you just may not like 440C).

440A, which most American mass produce knives are made of, is a softer, 55-57 HRC (hardness), with very good corrosion resistance, better suited to dive knives.

440C is a tough, high carbon stainless, 57-59 HRC, with some corrosion resistance, and is still used by some high end knife makers (ex., Jay Fisher, Entrek).

You are right though, D2 might have been a better steel for this purpose. But, it probably would would have driven the price up to about $300. 1095 steel, if heat treated well, would also be a good compromise in a pry tool, but would not have held an edge as well as 440C. Looks like Hoffner’s compromise was aiming for the masses, and not the elite users, here.

Unless you were just using it as a pry tool, it could use a forefinger quillon (guard) when applying pressure to the point, to keep the hand from slipping up on the blade when wet. Could have made it integral to the blade for little extra cost.

I personally know some first responders that would have this broken in 5 minutes. “Pry” with it, they’ll put a pipe on the end. Baton with it, they’ll do that with a sledge hammer. And the worst word in the world to use is “indestructible”. They’ll prove that wrong and want their money back. Seen to much in 22 years of working as a paramedic and being around first responders.

The 5/16 spine does it for me!

That’s the weight I wanna carry!