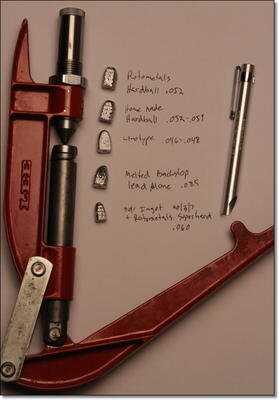

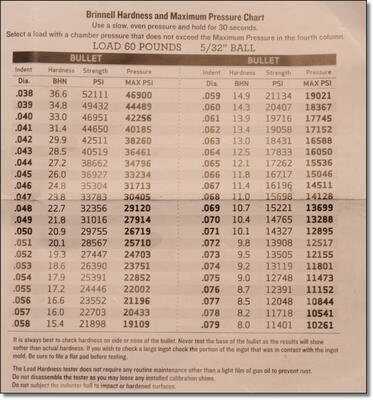

| NOTE: Please see part 1 of this series for an introduction to casting, and part 2 for an explantion of hardness, sizing, and other issues. In this article we take a look at using backstop fodder as a basis for free lead, in comparision to purchased lead alloys from Rotometals, a company specifically selling alloys for casting bullets. We used this Lee hardness kit for the testing. It dimples the metal and you use an included microscope to measure the dimple. We covered how to use the hardness kit in our last casting article, and the basics of casting in the first article in this series. If you look at this chart, the .052-.054 we got for a hardness measurement on our two “hardball” alloys corresponds to 22,852 to 24,703 PSI. According to the Hodgdon online data center, that should handle most standard pressure handgun loads, including 45ACP and even 9mm up to 1100 feet per second or so with a 125gr. lead roundnose. The base for these alloys came from range fodder from an indoor range. They hire a third party to remove all of their lead due to ridiculous regulations from OSHA, but they let us steal some for these tests. The first step is to fill up your melting pot with the smashed up fodder. Then just leave it to melt. You could even guestimate how much lead you have in the pot and make your alloy in one shot, within loose parameters. We found that by weight, the jacket material and slag scooped off the top comes out to just over 25% of the total weight of the range fodder at the start. Re-melted with a two ounce piece of tin wire and a six ounce chunk of antimony (at the top), it came out to roughly the same 92/2/6 percentages of the hardball alloy from Rotometals, where we also bought the tin and antimony. Turns out that antimony is difficult to work with in casting bullets. It melts at almost 1200 degrees, and our 117 volt Lyman put was like the little engine that could trying to get it melted, but we have no idea if it mixed properly in the alloy, because antimony apparently doens’t mix so well on its own. The bullets seem fine though. You could even guestimate how much lead you have in the pot and make your alloy in one shot, within loose parameters. We found that by weight, the jacket material and slag scooped off the top comes out to just over 25% of the total weight of the range fodder at the start. We also bought this 7 pound block of “hardball alloy” from Rotometals for a comparison. It is 92/2/6, lead, tin, antimony. As you can see from the top picture, they were virtually identical. The harder your alloy, the more difficult it is to get the bullets out of the mold, because they shrink less on cooling. We use a piece of wooden 2×4 and whack the handles, not the aluminum mold. They drop free after a couple whacks. All of these bullets were dropped into water to “quench” them, which makes them harder. Our last mixture utilized an alloy from Rotometals called “super hard” which is 70% lead and 30% antimony. It is meant to save you the hassle of dealing with and melting antimony directly. It melts at 650 degrees and there are no mixing issues. We tried it with this old brick of 30-1 (lead/tin) we had from making .45-70 bullets for a Sharps. It works out to 90/3/7, but the hardness didn’t seem to reflect what it should have on paper. There are always factors that effect the metalurgy of your final mix, and for some reason this one didn’t work out as planned, but such is the way of bullet casting. Don’t let it get you down. Load and use the bullets and you’ll find that they are usually fine for your purposes, and it’ll save you a ton of money on jacketed bullets. |

Rotometals (tin, antimony, Superhard source)

https://www.rotometals.com/bullets

Metallurgy isn’t a fuzzy science. When it comes to mixing metals, certain rules give you guaranteed certain results. But when it comes to casting bullets, the metalurgy isn’t as simple as you might expect. Small variances in temperature or handling can affect your bullets a great deal. But to a certain degree, you can count on a usable product with a given set of set variables, and that has been our focus here. For this article we decided to take a look at the mechanics of common casting alloys. You can buy completed alloys for just over $2-$3 per pound, but if you can find a free source for the main component of cast bullets, the lead, you can bring your cost down substantially. With the additions of small amounts of additional metals, your bullets can be made harder than pure lead, and this makes them able to handle more pressure and velocity. With virtually no sacrifice in performance, you can shoot just about any handgun caliber, and even some rifle calibers, using cast bullets, at a fraction of the cost of jacket rounds.

Bullet casting mixtures are generally made of a mixture of three metals. Lead comprises by far the majority of the mixture, and tin and antimony are added in varying percentages for desired specific effects. Tin adds some hardness to lead, but only up to about 5-10% of the total mixture. It also helps the mold fill out. Antimony adds hardness to casting mixtures, in proportion to how much you put in, but too much antimony and the bullets don’t cast well and will become brittle. Generally it is a give and take between the three metals, based on what you plan to shoot versus cost and performance. Arsenic is also found in casting alloys, but casters generally don’t add it themselves.

Our premise at the start of this article series was “free bullets for life.” In our first installment we tried to cast from pure “wheel weights” (the pieces of lead used to balance your car tires) but we couldn’t get any. We did find the stick on kind, but they turned out to be almost pure lead, and very soft, not the classic semi-hard alloy found in the clip ons. If you Google around, a lot of “bullet casting theory” is based on the easy acquisition of clip on wheel weights. But with the rising cost of raw metals over the last ten years, apparently the tire shops re-use their wheel weights now, and those that don’t recycle them for credit. Free wheel weights probably exist in some parts of the country, but they aren’t as readily available as in the past. Most of the casting data for wheel weights is useless if you can’t get them, so we really have to start back at zero, and experiment from here.

Backstop fodder is generally available, and that is our focus for the tests here. You can dig backstop fodder out of the burms at your outdoor range. It stays together in the dirt fairly well and it separates when you melt it in your lead pot. The copper jackets don’t melt and they just float to the top. We got lucky enough to find some indoor range backstop fodder for our tests. This isn’t as easy as you might think because most indoor ranges contract a third party company to clean the range. This is due to OSHA regulations, because even without handling lead employees at ranges have to be tested regularly for lead poisoning. If you have employees that handle lead it is even worse, and most range owners give all of their range fodder to an outside company that does the service of cleaning the range, while getting paid with the raw metals.

Our range fodder batch turned out to be about 75% lead and 25% jacket material when we melted it away. The lead part is apparently mostly just that, lead, as it was not that much harder than the pure lead stick on wheel weights we started with in the first article. We used this lead to make our own alloy using purchased tin and antimony, and it provided a great basis for comparison with purchased alloy ingots we bought online.

If you are using backstop fodder as a source of free lead, you will need to purchase some tin and antimony. We found a company called Rotometals that advertises on some of the cast bullet forums and as a mail order source for casting metals we can recommend them highly. Our order came quickly, and they have free shipping over $100, so when you look up the price of your metals, that’s the price, no guessing on the shipping charges required. Forty or fifty pounds of lead may seem like a lot of lead, but it goes quick and it is a smaller physical quantity than you would expect. There are 7000 grains in a pound, so one pound of alloy will yield only 30 .45ACP bullets at the traditional roundball weight of 230 grains. Forty pounds will yield 1200 bullets, for a hundred bucks. With a $30 brick of primers, a $20 can of powder, and your saved range brass, even only 1000 rounds at $150 is a steal at today’s ammo prices, and if you can just buy your tin and antimony from Rotometals, the cost of your bullets will go down to next to nothing.

Tin is the most expensive of the casting metals and most mixtures don’t use more than 5% tin. We ordered the tin wire from the Rotometals tin page, at $16.99 a pound. Tin also serves to inhibit the oxidation of antimony in the mixture apparently, up to a certain temperature, so it will help your alloys be more repeatable for the same results. You don’t have to add more than 2-3% tin for perfectly usable bullets that fill out the mold completely, and leaving it out isn’t advisable. Even heave, 400grain plus, slow moving .45-70 bullets will benefit from some tin, even at 30-1 lead/tin and 20-1 is a standard for low velocity handgun calibers.

Antimony is not as expensive as tin, $13.99 a pound, but there are some additional details you need to know about it. For one, antimony is really poisonous. Unwittingly we ordered a pound of it from Rotometals and broke chunks off with a hammer for our alloy experiments, probably inhaling dust. Antimony also melts at a much higher temperature than lead, 1167 degrees, so with our 117volt Lyman casting pot it took a while for the mixture to get up to temperature and melt the antimony. According to the best casting source online from the Los Angeles Silouette Club, antimony has yet another detail that it doesn’t mix well by itself either. Notheless our alloy worked fine melting it right into the mixture. Rotometals has an answer to the problems with antimony. They call it “super hard” alloy and it is made from 70% lead and 30% antimony. For bullets this alloy by itself would be far too brittle, but is made to cut other mixtures and pure lead without having to deal with the raw antimony. Super Hard melts at 650 degrees and because it is pre-melted and mixed, so you can add it into pure lead or lead and tin mixture to get an appropriate percentage of antimony, without having to worry about it not mixing right.

In our first alloy mixture, before discovering the implications of pure antimony, we attempted to duplicate the Rotometals “hardball” alloy at 92% lead, 6% antimony, and 2% tin. It just so happened that when we melted down a bucket of range fodder, we ended up with 92 ounces of lead, so we added 6 ounces of antimony and 2 ounces of tin. As explained, we hammered a piece of antimony off the one pound crystallized chunk that came from Rotometals,( and that isn’t advisable for health reasons). Live (thankfully) and learn as they say! From now on we use the super hard alloy to cut in antimony, or be a lot more careful with the pure antimony.

The results of this alloy were pretty good, even though the mixture got way too hot, oxidized a ton, and the bullets came out frosted, which is always a sign of a mixture that is too hot. Nothing ever goes the way you think it will when you are casting as a novice. We used a dipper to cast with these batches because the Lyman bottom pour pot you see in the pictures has never reliably poured from the bottom. With a too hot mixture you have to let the mold cool down for a while before you shake out the bullets. Otherwise the sprue plate will drag lead across the top of the mold, and the bullets can even droop when you drop them out. In this case it was probably a good idea to have the mixture too hot because it helped the antimony mix well, and you will see in your own casting that generally one problem always ends up being the answer to fix another problem, so you end up trying to find somewhere in the

In between our experimental alloys, we cast some of the purchased Rotometals version of “hardball” alloy, as well as some “Linotype,” which is made from 84% lead, 12% antimony, and 4% tin. Linotype is very hard and can be used for high pressure magnum rounds, as well as .30 caliber rifle bullets without gas checks. Historically it has been used to cut and harden clip on wheel weights as well. The name Linotype comes from the original purpose of this mixture, printing presses. It used to be that every issue of every newspaper had to be set up every day with new characters made of Linotype, that were used to press the ink onto the newspapers. Linotype, like clip on wheel weights, used to be easy to get. Today the mixture percentages are just a legacy, and a reference point for bullet casting. Many old recipes will say n% Linotype and n% pure lead, or wheel weights. For most purposes the Rotometals hardball recipe is fine, but we made some of everything to get out shooting for the next article.

As you can see from the pictures, our hardball mixture came out pretty close to the mail order Rototmetals hardball mixture in hardness, diameter and weight, so the two were indistinguishable, even though the casting conditions weren’t perfect. This is the thing about bullet casting. It almost never goes all right, but the result is almost always usable bullets, and that is really all that matters for most people.

There is some geezer science you should be aware of that may or may not affect how you deal with your own alloy creations. The harder an alloy gets, the less it “shrinks” when it cools. Shrinkage is how we get the bullets out of the mold so easy. All metal shrinks when it cools, but softer metals shrink more. The same mold, cast with a super hard mixture, will produce bullets with a greater diameter than the same mold with a softer mixture. Hard bullets stick to the mold more as well, just for this reason. When it comes to range rounds and lead bullets, you will find that 99% of the time you don’t need to size them and you can load them out right out of the mold. A thousandth of an inch or a little won’t make a noticeable difference in your loads, your accuracy, or anything else, and this is really all you see for a difference in diameter on the harder mixtures.

A phenomenon known as “gas cutting” is thought to be the biggest enemy of cast bullets. This is when you retrieve your fired bullet from the burm, or shoot it into water, and it shows signs of melting on the sides. This leads to a lot of lead left in your barrel, known as “leading.” Leading can also be caused by driving too soft a bullet too fast, so that it drags on the rifling. Other than that, gas cutting is more of a mythical creature than anything else. Some will tell you that gas cutting is caused by lead being too soft, and the pressure melts the base of the bullet. Others will tell you that it is from lead being too hard, so it doesn’t “obturate” (thanks for the correction guys lol) the bore when fired, filling the rifling, and it lets the gas get by on the sides, which melts it. We are going to shoot some of the these bullets in the next article, so we’ll see just how any of this plays out. Gas cutting and leading are real issues, but variables in the gun and the barrel have as much to do with it as much as lead hardness and bullet diameter. The best thing is to make a small batch that makes sense for what you are doing and try it. Light leading can be easily removed by shooting a jacketed round through the gun, so you don’t have a lot to loose.

To follow up on the discussion on heat treating from the last article, we did try to heat treat the hardball alloy from Rotometals as well as our own hardball recipe, and the third recipe we hadn’t discussed yet, and the Linotype and some bullets made from the pure range fodder. Again, the results were inconclusive. Quenching the bullets in water as they dropped out of the mold appeared to have some effect on adding some hardness, but at 450 degrees in a regular oven most of the bullets melted after about ten minutes and those that didn’t showed only a small increase in hardness, maybe two points on the BNH scale for hardness. On further reading, arsenic may be the key ingredient to make heating treating more effective, but who is going to buy arsenic? Wheel weights apparently have some arsenic, which is why you hear heat treating referenced by experienced geezer casters, but if you can’t get wheel weights you have to deal with what you can get.

The hardness measurements you see here may be accurate and they may not be accurate. Quenching and heat treating didn’t have the effect that you read about on the internet forums. Maybe it is just the arsenic, and maybe it is the Lee Hardness Testing Kit and the measurement methodology itself. By sanding one side of bullet flat, we could be both heat treating and/or work hardening or softening the bullets themselves. We tried using both a course wood rasp and a belt sander to make the flats required for the device, but both heated up the bullets at least some. And both are definitely modifying the surface to some degree from the original hardness. There are other hardness measurements, but if the Lee kit is close to correct, and at least relative to itself, we should have enough data to load these batches of bullets up to take to the range to test.

If you are already casting or just about to begin casting, this is a far from exact science, so don’t bother trying to nail your percentages perfectly. Lead, tin and antimony (as well as the superhard alloy for blending antimony) come in chunks or ingots. You can’t exactly heat up a butter knife and slice off how much you need. Approximate percentages are fine, and should give you close to the

results as if you had hit your target percentages perfectly. In our last batch for this test we had hoped to make a slightly harder allow for use with a .357 Magnum. The pressure of the .357 for a 125gr. round nose lead bullet, according to the Hodgdon website, should be loaded to between 13,000 and 30,000 PSI. According to the manual that comes with the Lee Hardness Kit, this would correspond to a hardness between 11 BNH and about 22 BNH. The BNH, or Brinnell scale, is itself an arbitrary numbering system, so don’t let your eyes glass over when you get into this stuff. The manual shows you the measurement of the dimple, with the accepted working PSI of the alloy you are measuring.

This batch for the .357 we had hoped would measure the dimple around .050, to make full snot .357 Magnum rounds, but even with some attempted heat treating in the oven (also almost no effect), it never got harder than about .054, which corresponds in the manual to a working maximum PSI of 22,852. The other alloys, our hardball and the Rotometals hardball, had measured .052, so they were a little harder. This batch didn’t hit the alloy numbers perfectly. We used an 117 ounce ingot of 30-1 (lead/tin) and 34 ounces of Rotometals superhard (70/30 lead/antimony). This worked out to about 90% lead, 3% tin, and 7% antimony. This is close to the 92/2/6 of the Rotometals hardball, but as we said at the start of this article, metalurgy is not a fuzzy science. This mixture will work in the .357 Magnum, but probably not at full snot strength.

We hope to return for our next installment with loading and shooting all of these alloys and maybe a couple more. If anything, bullet casting is an adventure in experimentation. In the home environment, you won’t be able to control all the variables, and until you develop a perfected system, your finished product will be as inconsistent as ours. But at the end of the day, you’ll have bullets that work and shoot well. Three bullet casters will give you four opinions, so beyond the research you can do in books and online, your own testing with your own guns will make more of a difference than anything else. And you of course will get your gun nerd merit badge for casting, well on your way to a full-fledged gun nut.

This is a good read i have done today so far, I am delighted to came across it. I\’ll be back again to check out other posts as well.

I was fortunate enough to obtain about 150 pounds of plummets lead. Does this stuff make good bullets. I am fairly new into bullet casting

Hello, after reading this awesome piece of writing i am

also glad to share my knowledge here with friends.

Batteries are a bad idea, so I would assume that the clamp on terminals would likewise be contaminated. The acid is very poisonous. I would be very careful.

Interesting read on all 3 articles. Looking to get into ammunition reloading and bullet casting. Curious, any experience melting battery terminal adapters (clamps) rather than wheel weights? Not sure how they rate as far as alloy compared to wheel weights. Have access to a pretty good supply from work. Thanks

The first word of the above post should be Arsenic not Asenic (corrected by the Author.)

Asenic is required for quench hardening. One 2 oz. clip on wheel weight added to your alloy in the pot will be enough.

To Heat Treat Bullets:

Heat the oven until a test bullet begins to slump. Back off 5 to 10 degrees and bake the bullets you want heat treated for 30 minutes.

After the 30 minutes take them out of the oven and immediately drop them in ice water. Wait 1 week and test with your Brinell tester, repeat after 1 month, 3 months and after 6 months. Then tell me the hardness hasn’t increased.

If you need a wheelweight I will send you some for an experiment. I have WW’s from a tire shop I worked at in 1972. If you have old wheelweights from the old days and want to heat treat bullets save them for a source of arsenic.

And why you coudn’t get any wheelweights for this experiment is a mystery to me. Ebay has 100’s of pounds of them for sale. Old vintage WW’s at that.

Note new wheelweights are contaminated with zinc and using them is risky as one contaminated weight can ruin a whole batch of alloy so always use a pyrometer in your pot to keep the zinc floating in the slag and get a bottom pour that works!!!.

In order to test an alloy for its ability to quench harden, you must wait at least a week before a Brinell test.

Redo the quench hardening experiment and wait the required time after the ice water quenching at least a week.. No hardening of the alloy means no arsenic was in the alloy.

It takes about a week for the alloy (if it has arsenic) to harden and that it continues to harden for about a year.

What is a “pyrometer”? Do all types of new wheelweights contain zinc, or are the new lead ones just like the old ones?

The problem is that wheel weights are made from scrap, so you just never know.

new stick on weights are zinc, old clip on-lead, anti.,tin. Zinc and lead do not mix. Throw the flat stick on away.

1984 Eh?

Great article! The one exception is that the word is “obturate” not “obfuscate”. “Obfuscate” means to “Render obscure, unclear, or unintelligible,” or “to bewilder”.

Yea spellcheck doesn’t catch those when you use an actual word as the typo lol. It has been corrected thanks.

As mentioned earlier, the bullet needs to obturate not obfuscate.

With reference to firearms and air guns, obturation refers to the process of a bullet or pellet, made of soft material and often with a concave base, flaring under the pressure of firing to seal the bore and engage the barrel’s rifling. To ensure a proper seal, the pressure generated by firing the cartridge must be sufficient to obturate the bullet material.

Tire stores don’t reuse but certainly recycle. Scap lead is soo cheap but pennies add up. Offer to purchase.

OR- go to a junk yard. Preferably the lowball, you-pull-apart. I would advise going in person, not calling. Inquire as to price… Take a thin chisel, hammer, channel locks and visegrip.

As far as sizing diameter forget the old advice of sizing to bore diameter or just one thousandth over. Do that and you will get leading and poor accuracy, because there is no such thing as a uniform bore diameter the entire length of the barrel. I have gone as far as 4,000ths over and got excellent accuracy as long as the diameter of the loaded round will go into the chamber of the weapon, rifle or pistol. For rifles gas checks are a must or you will get poor accuracy. Oversize bullets will not lead but the bases without gas checks become distorted and produce poor accuracy. The gas check does not prevent leading it only keeps the bases from being distorted from the powder gases.

Re:….. The gas check does not prevent leading it only keeps the bases from being distorted from the powder gases.

The Fellow IS 100% Corect “….. I use to do a LOT Of casting 35 years ago , using Only” wheel weights and Gas checks on mainly 44 mag. loads…. Bout 12 too 1300 fps. rounds out of my model 29 , 8 3/4 Targel barreled 44 mag. , I shot several thousand rounds through it , at a Steel gone I had placed @ 100 yd. rifle range . After I`d run about 600 rounds of the gas checked 240 Gr. rounds throught it , I`d run about 25 Jacked round`s through it to clean out any let over lead @ the forcing cone area of the barrel and seem to work just fine , untill I started losing a lot of accurcy , and I though I had finely burned up my barrel and needed to replace it . I took it to a gun smith to get a new replacement barrel put on it and He looked at the gun and said….. Quote” these Nothing Wrong with your barrel , Except the lands have a LOTA Lead in them . Told him I`d shot Several thousand rounds of bullets through it made from Wheel Wight`s , with gas checks on them all . He said he would charge me $100 bucks to clean it out to where it would shoot good again or I could do it my self . so I took it home and began the LONG Ghore of cleaning that thing out with lead removing tools I have and I don`t know HOW much Solvant`s I used , and about 100 hours later I FINLY” got all that lead out of the barrel , and Said I`LL NEVER SHOOT ANOTHER Pure Lead bullet out of any of my weapon Ever Again ! I had several other gun`s I Also worked for hour`s on cleaning them out also . I still have all my equipment to cast , and size lead bullets , but put it all away and haven`t ever use the equipment again . I Only shot jacked bullet`s through all my had gun`s after that go around untill they started making copper plated hand gun bullet`s , which work fine for the most part , but to this day I ONLY shot Jacked ” bullets through all my Magnun hand gun`s and ESP: ….. My Rifles ! One a person experances what I went through to save a lot of bullet money , Most people I`d think , would say , the HELL” With then lead bullets , Gas Checked Or Not” , Cause Fellows …. IT AIN~T FUN” , CLEANING That Burnt lead out of your barrels lands …. And ESP: A rifle barrel , I tell yall that . But those that wanta save your selfs a little money ….. have Fun and Injoy .

If you had hardened the lead this wouldn’t have happened. Any basic casting book back then would have told you that you can’t shoot magnum velocities with straight wheel weights. Linotype would have most likely worked fine.

First of be sure to wear a dual filter mask that filters out lead fums even when casting out in your garage with the doors open. Use heavy leather gloves, you can even get elbow length ones at the local welding supply stores. Use safety glasses. All these safety articles are a must

Generally I have no trouble finding wheel weights. Make no mistake about them they are now just like everything else being made cheaper with no tin in them whatsoever unlike the older made wheelwrights. I use 75 percent wheel weights to 25 per cent Linotype or 1 lb of 50/50 bar solder in a 20 lb pot, make sure it contains tin.

When the mold overheats and it will very quickly simply dip it in and out very quickly in very hot tap water,it will not warp it. Use a 1 gallon milk jug with the top cut off to put the water in. Also after every cast press the sprue plate against a wet rag to cool it down so yo do not smear lead under the sprue plate. Watch out, any moisture that gets into the lead pot will cause and atomic explosion.

or ya can just use 2-3 different molds, and slow down a little,or turn the heat down, I cast 38 with a 44 or 45. HOT lead and WATER do not mix !!!!!

I was fortunate enough to be able to collect about 250# of lead wheel weights before I started casting. I have kept the entire operation very simple. First, I melt a cast iron 3 quart pot full of wheel weights over one of the burners of my Coleman stove. I then skim off the steel clips and other impurities that float to the top. Then I use a steel ladle to dip into the molten metal, and pour it into the cavities of an aluminum cupcake mold. Later, I plug in my Lee 20 lb. lead melter, and set the thermostat to about 5. I then ad 3 or 4 “cupcakes”, and walk away to find something else to do. I return in about 45 minutes, grease up my Lee molds, and start casting. I rotate between two different molds, putting one down when it gets too hot. I hold a piece of wood in my right hand for tapping on the mold to help it release the bullets. I drop the bullets into a 5 gallon bucket full of water, not so much to harden them as simply for convenience. That way I don’t have to worry about setting my bench on fire, or having a hot bullet roll off onto my leg. Later I remove the bullets, spread them out on a towel, let them air dry for a few hours, then I put them in a plastic quart jar, add some Lee bullet lube, shake them up until all the bullets are covered, then spread them out on a sheet of wax paper so the lube can dry. I don’t push the black powder bullets through a sizing die, which would be a waste of time, but I do size all my pistol bullets. It only takes a few minutes to do that, and then I know I have eliminated at least one factor that interferes with consistent velocity, pressure, and accuracy. After sizing, I put the bullets back into the plastic quart jar for a final coating of lube. I have never used antimony or tin or anything else, just pure wheel weights. Once in a while I get an imperfect bullet, one that didn’t completely fill out the mold. So what? I throw it back into the pot for the next casting session. I am pushing 125 gr. .357 bullets fast enough to go completely through a big city phone book and a 3/4″ pine board behind it, while experiencing almost no bullet deformity or mushrooming, and almost no barrel leading. I can’t imagine why anyone would want to ad any other metal to the mixture for even more hardness. I like Blue Dot powder for my pistols, IMR 4064 for my 30-06(jacketed bullets),Winchester primers, and Pyrodex for my rifled muskets.

Thankyou for some interesting articles. I’m now 53 and originally learned how to shoot in the Boy Scouts. My parents wouldn’t allow guns in the house and the ex-wife wasn’t to keen on them either. The Air Force (in general) isn’t really a “gun crowd” so to speak, so I’ve been away from shooting for quit some time and I’m just starting back into it. I’m interested in learning how to re-load but haven’t started yet. I would assume it would be best to learn reloading first, before moving into casting bullets? And as a historical question, when and why did jacketed bullets come about; I assume it was to make a harder projectile more easily for mass production? As I understand it (and this probably goes back to before mass production) a bulett mold came with the purchase of the gun; so there was a time when this was an ordinary task?

With the use of smokeless powder and the increase in pressure they caused, cast projectiles leaded rifle barrels. Although several bullet lubes were found to be affective, a jacketed bullet was the best answer.

Tengo que utilizar moldes ceramicos para fundir balas de plata, y no encuentro munición de esta densidad

Good article. There is so much dated info out there. It is good info. but, as you say several times, the stuff they talk about is no longer commonlt available. Thanks for the update. BTW, I think it is possible that “obturate” is the word that describes the bullet base deforming to “seal” the bore. Cheers.

+1 on the turkey fryer/dutch oven. I was about to suggest the same thing.

The other thing here–if you want to get your bullets out easier, buy some mould release or use a lighter (not a torch, a lighter) to put some soot onto the cavities in your mould. This helps them fall out easier.

Mold release does help some, with some alloys, but it doesn’t work so well on aluminum like it does with steel. Smoking the molds does little to help aluminum, which is why it isn’t suggested here.

Please make sure when you melt jacketed rounds to extract the lead, that they have either been cut or smashed so you can see the lead inside. I have personally witnessed jacketed rnds “pop” in the molten lead spewing hot lead everywhere. When I melt reclaimed rounds from indoor or out, I use a large cast iron dutch oven with a heavy lid on my gas fired turkey fryer. This allows me to get it hot, do it outside and use something with a lid on it.

Great Article, keep melting….