An AR-15 is a relatively simple machine in the grand scheme of things. With only about 200 parts, the design can be assembled in less than two hours by anyone with a pin punch, hammer, and marginal intelligence.

But if you’ve tried to build or modify an AR-15 for extreme accuracy, you quickly learn that “simple” doesn’t always mean “easy.”

Virtually any part or component of an AR-15 can affect accuracy. Some will affect it more than others, but it can be tough to know where to start.

I spoke with Mike Ross of Criterion Barrels, and he emphasized the importance of taking your time, choosing components carefully, and getting some expert advice.

“It’s not rocket science. But you hear a lot of guys talk about AR-15’s like they’re Legos for adults. Personally, I could not disagree with them more,” he said. “Anyone can throw them together. I’ve built them with 7-year-old girls, and they can do it just fine. But there’s a difference between just slapping a bunch of parts together… and building them properly.”

“Build properly” is what I’m going for here.

Some of these strategies will affect accuracy more than others. I’ve organized them (more or less) from “will really affect accuracy” to “might affect accuracy.” You can use one of them or all of them. It just depends on how much money you’ll willing to spend and how many you want to implement at once.

1. Get a High-Quality Barrel and a Bolt that Fits

In my experience tinkering with bolt action and semi-auto rifles, the barrel is the most important factor in determining accuracy. You can improve around the edges, and an out-of-spec component can significantly reduce shot-to-shot consistency. But all things being equal, accurizing starts with upgrading your barrel.

There are lots of high-quality barrel makers out there, but Criterion is one of the best. Criterion was founded by Steve Dahlke and John Krieger in 1999, and they produce match-grade barrels both under their name and for some of the top gun makers in the country.

For this project, I wanted to try out their new Core Series chambered in .223 Wylde with a 1:8 twist. The Core Series applies what Criterion has learned about precision bolt action barrels to the AR-15 platform. The barrel’s continuous taper allows the thicker portion of the barrel (between the chamber and the gas block journal) to heat and cool evenly, which helps maintain accuracy.

“We went off the deep end with gun nerd stuff with the Core barrels,” Ross told me. “Vibration confinement and heat dissipation and harmonics. All of that stuff went into the engineering. It was tested and validated.”

The Core Series is constructed from 4150 CrMoV steel and uses Criterion’s proprietary chrome-lining process, which they say provides all the benefits of chrome lining without degrading accuracy. The rifling is honed and hand-lapped, and the chamber is polished.

Along with a nice barrel, Ross also noted the importance of proper headspace.

“A lot of guys buy barrels without headspaced bolts, and then they don’t have headspace gauges. But it’s a critical component. There’s an .008 inch range between SAMMI minimum and maximum. You still might have a really inconsistent gun,” he said.

Ross recommends purchasing a rifle and barrel combo that has already been headspaced with a .001” headspace clearance. That will provide a more consistent seating depth and chamber pressure, both of which yield better accuracy. It also helps maintain proper timing and reduces wear and tear on internal components.

I went with the 18” barrel with a rifle-length gas system along with a properly headspaced BCM bolt.

Cost: $379.94

2. Use a Quality Handguard

How does the mental tube that keeps your hands off the barrel affect accuracy, you ask? Good question. You’re buying a quality handguard for two reasons, Ross said. First, you want a steel barrel nut that won’t touch the gas tube as it passes into the receiver.

“If your gas tube isn’t totally free-floated, neither is your barrel,” Ross explained. “Barrels are like giant tuning forks. If you think about hitting a tuning fork on a counter and watch it vibrate, if you touch it, it changes the way that it vibrates. It’s really no different than when there’s torque on your gas tube.”

Second, you want a solid handguard that won’t flex if you use a bipod. Ross said that he’s seen some of the budget-friendly handguards warp and bend when a bipod is loaded, which could also potentially interfere with barrel harmonics.

I opted for 15” M-Lok CMR from Centurion Arms. As you can see the barrel nut is low-profile, so it won’t contact the gas tube like the other barrel nut in the image. Plus, the 6061 T6 aluminum and Type III hard anodized coating is rugged, and the entire product is well-built by Americans on American machines.

Cost: $240

3. True the Upper Receiver

I understand there is some debate as to how much this affects accuracy. But Ross told me that he’s had hundreds of experiences with upper receivers that weren’t perfectly square, and I’ve put this step in the third spot because it must be done before bedding the barrel.

If you’re unfamiliar with the process, it requires purchasing an AR-15 receiver lapping tool, like this one that I bought from Brownells (about $35). The goal is to square the face of the upper receiver (the forward end of the threads) to ensure that the barrel extension sits flush and true.

Lubricate the pilot section of the tool (the part that goes into the upper) and apply 180 grit lapping compound on the lapping section of the tool, as per the instructions. Be careful not to get any compound on any other part of the tool. Secure the tool in an electric hand drill, and with the receiver held securely in a vice block, apply firm forward pressure using a moderate drill speed for 10-15 seconds.

My receiver probably didn’t need it. I completed this process twice, and by the end it was polished evenly all the way around.

Cost: About $45.

4. Ensure Proper Barrel-to-Receiver Fit

You should eliminate any kind of movement– what Ross calls “slop” – in the barrel-to-receiver fit.

This is “one of the critical points that will result in more consistency,” he said. “It makes for a better, more consistent gun.”

You can do two things to keep the barrel secure.

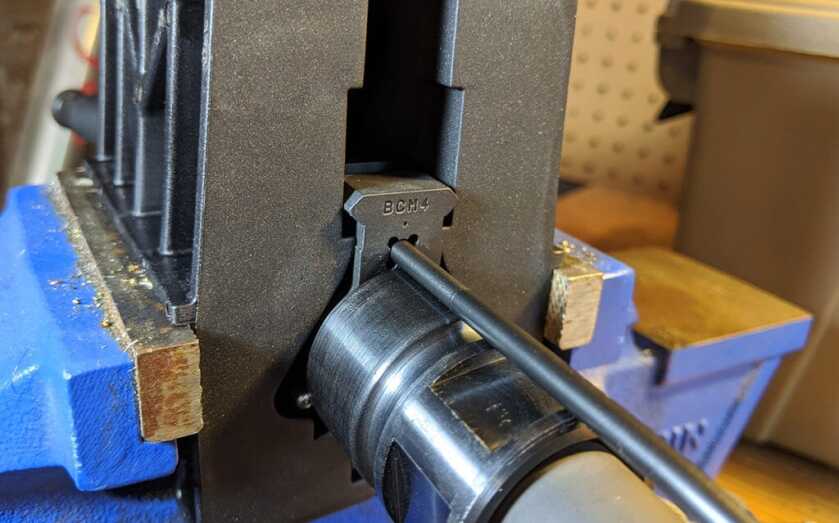

First, purchase an upper receiver that holds the barrel extension firmly. Bravo Company Manufacturing makes receivers with barrel slots slightly undersized for exactly this purpose. You may even need to heat the receiver to allow enough room for the barrel (what folks call “thermo-fit”). This wasn’t necessary for my barrel, but it was still an extremely tight fit. I had to tap the back of the receiver on the table to coax the barrel the last ½ inch into the receiver.

Second, you can “bed” the barrel in the receiver using a green Loctite compound. Ross said both Loctite 609 and 680 work just fine, so I went with the 609. Simply coat the barrel extension with a thin layer of the compound, slide it into the receiver, and wipe of all excess compound. Also make sure none of the compound worked its way into the receiver.

Finally, tighten your barrel nut to the recommended torque weight. The instructions that came with my handguard recommended torqueing the nut to 30 ft/lbs, backing it off, torqueing to 45 ft/lbs, backing it off, and finally tightening it to 60 ft/lbs.

Cost: About $130.

5. Tune the Gas Tube

I hesitate to mention this step because it’s a major headache, and I’m doubtful as to its impact on accuracy. But it follows the same logic as Step 2, and I’ve seen it recommended in AR-15 gunsmithing manuals.

In this step, the idea is to make sure the gas tube doesn’t touch the upper receiver as it passes through the hole. Dry fit the gas block and gas tube and see whether the tube contacts the receiver. If it does, remove the gas block and tube, and bend the tube to try to compensate for where it touches. If the tube touches the right and top of the receiver hole, for example, bend the tube left and down, and dry fit it again.

Don’t overdo it and bend it too much. But don’t be afraid of giving it a healthy torque since you don’t want to be doing this all day (trust me).

Again, if you’re in the mood and you think it’ll help, go for it. If not, I wouldn’t worry about it.

Cost: Free (and a massive headache)

6. Improve Practical Accuracy with a Trigger and Furniture

So far, I’ve only been discussing methods to improve mechanical accuracy – how your gun would shoot in a vise without any human input. But shooting from a vise is no fun. You also want to improve the gun’s practical accuracy – how your gun shoots with a homo sapien behind the trigger.

Lots of things might affect practical accuracy. I’m only going to talk about two – the trigger and the gun’s furniture.

Any high-quality aftermarket trigger will likely make you a more accurate shooter. A trigger with a lighter, more consistent break means you won’t move the gun as much while performing that critical step. For this project, I wanted something specially designed for precision shooting: the JARD AR Set Trigger.

Set triggers are most commonly used in the precision bolt action world. The JARD model allows shooters to push the trigger forward and “set” it for a 13oz pull weight. If you’ve never used such a light trigger, it takes some getting used to—but the payout is well worth the effort.

But here’s what I really like about JARD’s design: you can also use the trigger just as you would any other AR-15 trigger with a 4-4.5 pound break. This dual functionality means that you can use the trigger normally for rapid-fire work and use the set function for precision work. Plus, you don’t have to worry about accidental double-taps. Every time you use the 13oz pull weight, the trigger resets back to the 4-pound weight. Click here to read my full review of the Set Trigger.

A comfortable pistol grip and butt stock are essential as well, and I went the Stark One AR-15 grip and Magpul’s MOE SL stock.

Cost: $315

Results

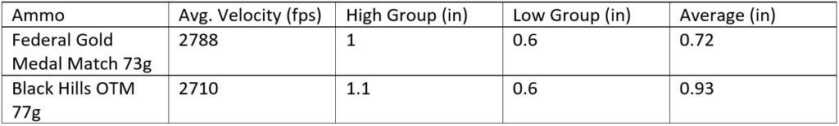

Ross recommended 77g OTM ammunition from Black Hills Ammunition for use with this barrel, so I went with that and a 73g Gold Medal Match cartridge from Federal.

Ross said that users should expect sub-MOA accuracy with match-grade factory ammunition, but that Criterion barrels really shine with a well-tuned reload. As you can see, these preliminary results show promise.

Conclusion

I didn’t implement every accurizing strategy – not even close. Ross mentioned using a heavy bolt carrier group and buffer, for example, which I didn’t do. If you’re running a muzzle device, be sure it’s installed properly and tightly, and try to make sure the handguard doesn’t contact the dust cover rod. You can also find lots of advice on internet forums about polishing surfaces for a smoother action and using the muzzle brake to tune the barrel to a specific ammunition.

You can try all of it at once or just pick one or two strategies to try. That’s the great thing about AR-15’s. They’re endlessly tinker-able, and if that’s your thing, America’s rifle is a great option for your next project.

I have a bunch of ARs, but don’t have any “mental tubes.”

When you finally went to the range what distance did you shoot from?

I stopped wasting time bedding barrels and truing recovers. I tried several times before and after tests to see if there was any significant changes and found nothing.

Now I just buy quality barrels. Noveske, White Oak, Larue, Wilson, and JP… It’s funny I’ve had a lot of poor luck with criterion barrels, so I kinda avoid those. When I can get better groups out of a light weight contour Noveske even after its hot…. yea.

The trick with the triggers is lock time. Hyperfire triggers really take the cake when it comes to lock time, but JP, Larue, and Geiselle also have some amazing triggers for a precision AR.

Great article. Do you fave a printed version? I want it to add to my ink an paper library

All good tips but most people cant shoot to their weapons capability before accurizing. Most people need to go straight to replacing their milspec triggers with a good aftermarket trigger. I’d also suggest an anti tilt buffer so you stay on target.

really nice article, however at the end most everybody wants to know it the price spent on all of this add on’s/improvements. can you possibly elaborate on the value by chance? thanks

Hey, Matt. Great idea. I’ve included the costs for each step.

Interesting observations, but missing a few I’ve found to be quite key. First, though, I wonder why you would want the gas tube to not have support where it enters the upper–the gas key on the carrier will be slamming home into the end of the tube with each cycle, so I find that a precision alignment relative to not inducing flex in the tube is very important. I also true the inside of the upper on occasion–they sometimes do have irregularities that can induce lack of concentricity of the carrier–which can then induce a world of problems with the bolt going into a precision lock with the extension.

People tend to overlook the precision of the pickup of the cartridge from the magazine in tuning the AR, IMO. In fact, I’ve found this induces more inaccuracy in the shot than any other factor, simply because the bullet itself has to navigate it’s way into the chamber with as little damage as possible to retain it’s balance and concentricity. It can also effect all the other functions in the process of cycling. It’s worth the extra money to buy a matched set of upper and lower IMO from a reputable maker.

yes i truly believe in your comment on the match set of lower and upper. in my early days of building ar’s i was so concern with money, mainly because i didn’t have very much to be spending on guns. i did find though putting those guns together i was constantly shaving bits here and there to make the feeding better. magazines were also i big problem with me as well.

Triggerpull,

The twist rate of 1-7 on my 20” barrel 5.56 Palmetto Fire Arms AR15 should have given me better groups with heavier loads of 62 grain on up in both 223 and 5.56 . I have tried other brands of ammo as well . What has worked and tightened my groups up to a 1”or less at 100 yards was Hornady 223 55 grain spire point .

Your comment and mention of the feed is of concern as my AR has shown brass fillings within the bolt carrier group to be more than what I think it should be . Any suggestions would be greatly appreciated.

Sincerely,

Mark

I’m not an expert–so take my comments with a grain of salt–nor is it possible to do a function-check by words over the internet. ; ) Your brass shavings may be brass–but they could also be copper from the bullet. I’ve found these to be due generally to the cartridge dragging/hitting things like the ramps and lugs–but can also be a consequence of gas timing (in other words when the carrier recoils and the bolt extracts the case from the chamber). As mentioned in the article–a straight-on match of the bolt to the extension–with “proper” headspace can make a big impact on how well the system cycles. While the article focuses on home-builders–even the big manufacturers can (I would say often) produce guns that are “out of whack”–they generally make things that drift towards the upper-end of SAAMI specs in order to make their guns work wit the widest range of factory ammo as possible IMO. In regards to your particular problem–assuming you have the right tools and knowledge to do it–take the receiver apart and reassemble it taking care to make sure the parts are trued well. Another aspect not mentioned–but aligning the gas block and tube properly is extremely important. Manufacturers tend to oversize gas ports a bit (again, just my opinion) in order to increase the cycling reliability over a wide range of ammunition types. I frequently read of double-stacking and other issues and people almost always figure the gun is under-pressured–my experience has been they are almost always over-pressured.

I have the ability and tools to check a few things .

Thanks