If you use or carry a particular handgun then you likely have at least one holster for it. This day and age, there are probably more off the shelf options for holsters than ever before. However, if the handgun you intend to holster is a brand new design, out of production, or just an oddball you may not have many options available. If you’re a left-handed shooter like I am then you have probably found that you don’t have too many options even with common handguns. Or perhaps you just finished building a pistol, and now you’re looking for a good DIY option to holster it. Or maybe you’re just looking for a quick, inexpensive, gun-related project. If any of the above applies, this article is for you.

I happen to be partial to leather for most holsters. However, at this point in time, I have no real experience working with leather. Fortunately, Tandy Leather sells holster kits that are obviously aimed at folks like me. They have a few different options available. My local Tandy store stocks most of these. For this project, I purchased the Bullseye Concealed Semi-Automatic Holster Kit. It’s an inside-the-waistband holster, obviously intended for medium-sized pistols. It’s not particularly expensive, $18.99, and it contains almost everything you need to make a holster. All of the hardware is included in the kit. It even comes with the needle and thread. The more astute of you probably noticed that I said I’m left-handed, but the holster in the link is right-handed. You would be correct. I had no luck in trying to locate a left-handed holster from any of the hobby stores in my area, though some did sell similar holster kits. Fortunately, you can get any of the holster kits Tandy sells in left-handed form. You just need to contact them directly. I asked at the store and ordered one through them. They offer another kit for small-sized handguns as well.

Most of you probably caught on the “almost everything you need” remark about the holster kit. The leather components in the kit are cut and already have the holes needed, but they’re just bare leather. You should put some kind of finish on it to better protect the leather and for aesthetics if nothing else. There’s a bunch of ways to do this. I used Tan colored Eco Flo Waterstain Leather Dye and this finish. Lastly, I used Brown Edge Kote to treat the edges. I purchased all of these items from the Tandy Leather store, but you can probably locate them from other sources as well.

Obviously this holster is a universal type, and not specific to one particular handgun. However, you would probably like to have an idea as to what handguns will fit this holster before you purchase it (unless you’re one of those guys who starts a whole AR build from an extra pistol grip you had lying around), as obviously not everything will fit. After I finished the holster, I tried a few different handguns to see what would fit. I got with a couple of buddies to try their pistols and tried the common handguns I own to try and get an idea of what would fit. I found that a commander sized 1911 fit quite well as did a CZ85. However, a polymer80 G19 build & a Sig 320 Compact both would not fit. I tried both a Glock 17 and a 22, and both would fit. Full-sized 1911s, and Hi-powers (not Hi-points), both stuck out the bottom far enough that the front sight would likely snag on the draw. Just because I had one handy to try, an IMI Jericho (AKA Baby Eagle) fit nicely as well. Hardly a completely inclusive list, but hopefully enough to give you an idea as to what would work with it. If your particular handgun won’t fit this holster, they do have others available.

The first order of business is to color and finish the leather. This is backward from most firearm builds in that we’re putting the finish on first as opposed to last. I started with the Waterstain leather dye. I found that I needed to apply several coats of the Waterstain dye to get the color fairly even. It came out as more of a brown than a tan, but it’s pretty close to what I’d wanted for color. If you wanted to have an easier way to do this, a black color finish is easier to deal with from what I’ve read. After the dye had dried, I applied the finish. Then I applied the Edge Kote. I used a special tool for this purpose (it helps you to apply edge treatment evenly), but you could just use a q-tip or something similar, though I suspect it would take some care to keep it even.

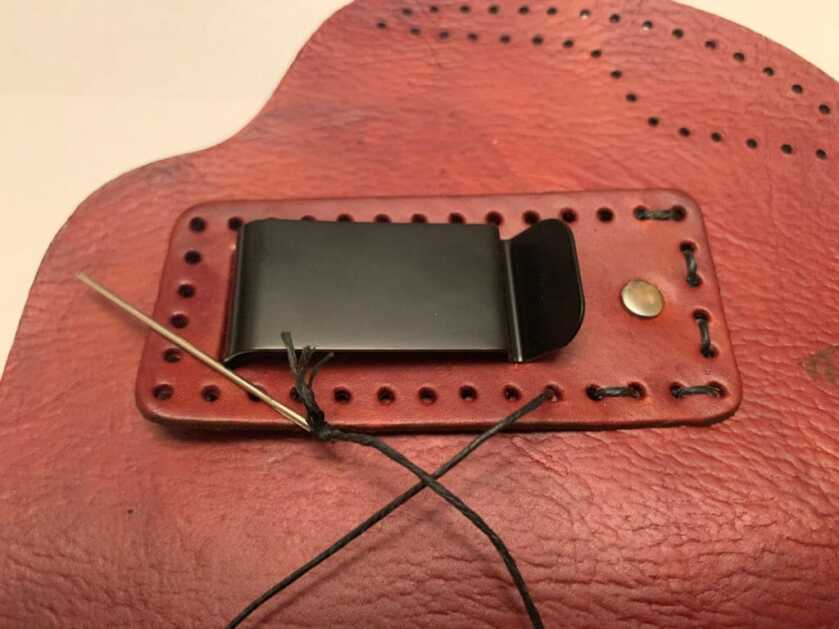

After putting a finish on the leather, the next step is to attach the clip to the corresponding leather piece. This is done with a rivet, which the kit comes with. You need a rivet setter, or you could make one if you have some metalworking skills, as it’s pretty simple. At any rate, slide the clip into the slot in the leather tab. Line the holes up and put the rivet through them. Then use a mallet and the rivet setter to smash the rivet into place. This is one of those tasks that it takes longer to accurately describe it than it does to do it.

Once the clip is riveted into place, it’s time to sew the leather tab onto the main holster component. The holes are already in both pieces, so it’s not terribly difficult to do. I’m pretty sure that even if you had no sewing experience, you could figure this out. The instructions are fairly clear. When you start the needle leave the end of the thread with a little bit extra hanging out between the leather pieces. This is what you’ll knot the thread off to when you finish sewing the part on. Go around once, and then go around again. You’ll see that once the second pass, the thread is going in and out in the opposite direction as the first, “adding thread to the gaps” so to speak. Once you’ve gone around again, knot the end to the thread you left out on the other end and trim the ends.

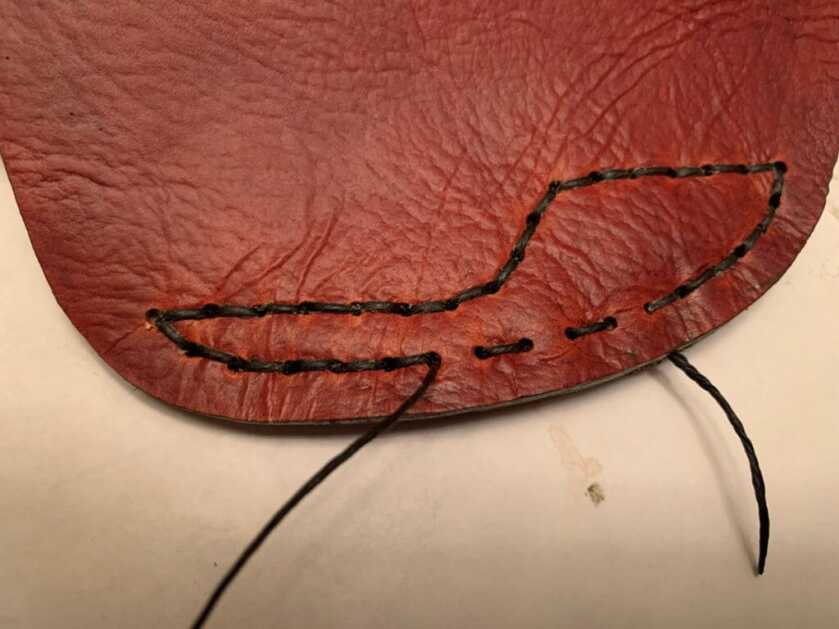

Sewing the main components together is done in a similar fashion. The remaining thread is for this purpose. Fold the holster in half, and line up the holes. The instructions showed the starting point to be on the outside, kind of in the middle. As long as you start in the outside row of holes, I don’t suppose it matters that much. Like the tab, start the needle through the holes of the parts and leave a bit of thread hanging out between the two parts. From the start point, go around the pattern of holes making sure to pull the thread tight as you sew. Like the tab with the clip, go around again. Then tie off the thread to the bit sticking out and trim the ends. Now your holster is complete and ready to use!

Prior to this project, I lacked any real experience in leatherworking. So I’m fairly confident when I say that this project is well within the skill set of almost anyone. It is not particularly complex or time-consuming to complete. The total cost of this project was about $70, and you could cut that down a little if you wanted to. So, if you’re looking for an inexpensive, weekend, firearm project, take a look at the holster kits from Tandy Leather.

Just a note. I used this kit also. If you “Pre-Sew” the holster together then wet the leather you can use a Tandy leather “boning” tool to hand form the holster using rubbing, pressure to set the leather to your particular gun. Nice little Personal touch.

Good info. guess one can follow the plan and adjust to form one for a 2in revolver?

Like this article this will be my next project.

For squidizen: a plain old standard sewing machine as found in the back of many closets, will sew a mouse pad…if it’s a thin one. Set the stitch width at max and with a heavy duty needle and thread use the hand wheel, not the motor and it may work wonders for you.

Now- to make a very form fitting holster: Carefully wrap your gun with several layers of Saran Wrap, then force the gun down into it and soak it in hot water for several minutes. Force the gun in again, pushing firmly. Wrap it in an old towel ( the leather may stain it permanently) and let it dry slowly over a couple of days. It’s probably a good idea to re-do shoving the gun in several times since the gun may creep back out a bit . Try to do this before using the stain for a more even finish. For spot stretching of leather use 92% isopropol alcohol (weaker solutions contain too much water), and this even works on pre-dyed leather. Soak the desired spot with a bit of alcohol and force the gun into it to stretch the offending area. Use a hair dryer on low heat to quick dry it if you’re the impatient type. Remember that the alcohol is highly flammable, so use caution. Don’t forget to re-oil the gun well before you put it away.

Also, for pocket pistols you can make ugly but functional concealed carry holsters from an old mouse pad. Needs to be the kind that has cloth on top with non-slip rubber on the bottom but not too thick. No sewing necessary. Wrap it around your pocket rocket with the cloth inside so it fits perfectly, punch holes with awl in appropriate places, rivet together. Then cut off the excess so it fits in your pants pocket just right and is easy to draw. Finally an inside-the-pocket holster that fits your mouse gun right, imprints like a wallet and costs next to nothing.

Looks like it could be an ambidextrous kit or am I missing somthin ?

You can purchase a “sewing awl” and waxed thread for holster projects. I’ve recycled old cowboy boots when they become un repairable. The leg sections may contain ornate stitching and exotic skins that cross over well to holster use. Measure and mark your stich length and pattern. Hole punching plyers make stiching easier. You can add a layer or two along the outside seam so there’s trigger space without a wide pinching taper. I’ve made three SAA holster in the past. Add a hammer loop and leg tiedown if desired. You can do belt cutouts or the over belt loop that the holster body snugs into.

Seem like just about everybody has time on their hands now, got old boots? Lol