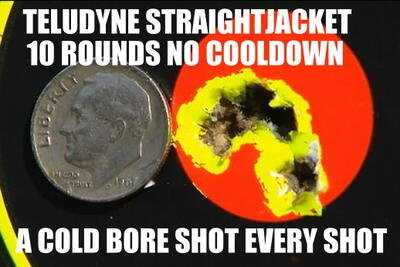

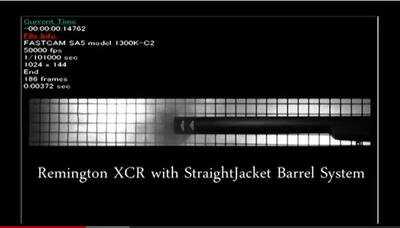

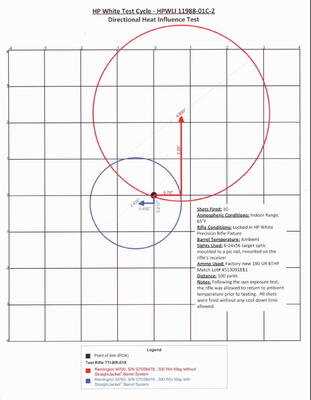

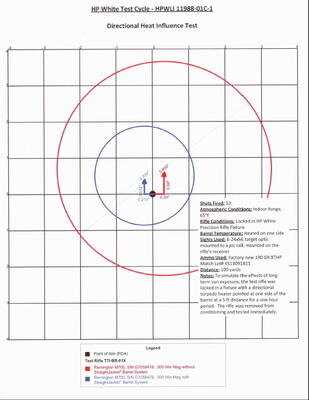

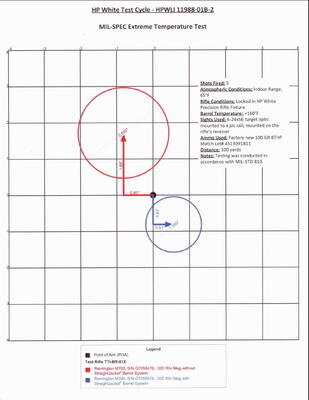

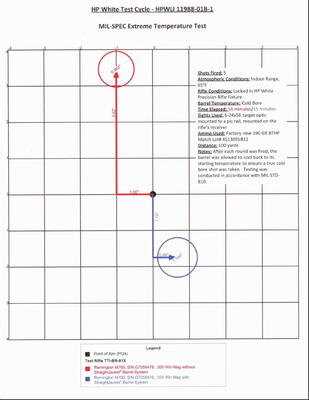

| The Teludyne StraightJacket is a product we found over a year and half ago at NRA Show 2010. We later tested it at length and broke the story in December of 2010, with our article, Ultimate Accuracy Makeover. httpv://www.youtube.com/watch?v=qqUnmwAlwY4 This is the company video if you would like an overview of what the StraightJacket system is and why it is. The profile of a StraightJacketed rifle is 1.25 inches thick. Teludyne press fits a steel or now titanium sleeve around your barrel and pours in a proprietary media, then welds a cap on the jacket, and finishes it off with this muzzle brake that can also be replaced with a standard muzzle cap for F-Class and other shooters who aren’t allowed to use a muzzle brake. In the video you will see some side by side comparisons of slow motion video comparing the flopiness of a standard long range rifle vs. a StraightJacketed rifle. Click for a bigger version of these graphs, or download the PDF to print everything out full size. This is an example of 10 rounds with no cooldown after 20 rounds to heat up the bores. The brand new Remington 700 in .300 Win. Mag. shot into about 4 inches before StraightJacket, and 2.6 inches after. It may be blasphemous to question the veracity of the “fixture” at H.P. White, but after seeing a real fixture up at the lab at the US Army Marksmanship Unit at Fort Benning, we would be suprised if the H.P. White fixture is up to snuff. Our US Army Sniper Ben Becker would like to try this rifle in the same test. In our experience with regular hunting rifles with StraightJackets, even after more than 20 rounds the StraightJacketed gun should have shot until well under an inch. This was one of the tests that mimicks having to sit in the sun with your rifle before having to fire ten rounds in succession with no cooldown. In this one the rifle was allowed to return to ambient first after having the heater on it for an hour. There is still a drastic difference, though again, we question the 2.4 inches on the StraightJacketed gun. This should have been under an inch as well. This is the 5 round Mil-Spec testing at 160 degrees of uniform heat. Every branch of the military is evaluating the Teludyne StraightJacket, many in the field under fire already. This is an older story than many people realize. This was a titanium StraightJacket we got to hold at SHOT Show. A StraightJacket is a fraction of the weight that an 1 1/4″ heavy barrel gun would be, but the titanium gave the rifle better balance than the steel jacketed guns that were made for us in 2010. Invest in the titanium if you plan to use this gun in the field or for 3-Gun competition. Even though the H.P. White tests show dramatic results with the StraightJacket, this is one of the targets that brings into question the veracity of how much true performance they measured. The point of this graph is to show that it took the Remington 55 minutes to cool down to ambient for 5 “cold bore” shots before the StraightJacket, and 15 minutes after, but look at the sizes of the groups. In our experience the only thing that opens up the StraightJacket groups over shots is shooter error, even Ben’s. That in the 10 round tests the group opens up to 2.5 inches or so brings into question the veracity of the H.P. White fixture. Maybe we should be happy that there is finally proof, but it is only half the story. The AK-47 version of the StraightJacket is something we would like to check out this year, and we happen to have a AK-47 in the safe that we have no romantic involvement with at this juncture. Could there be a StraightJacket in its future? This rest in the video looks suspiciously like a HySkore machine rest, and we have found these to be extremely course and not capable of what Ben can shoot on a bad day, let alone a good day. Please don’t say we didn’t warn you if you wait to call Teludyne and can’t get your rifle done as soon as you want for a big hunt, or Camp Perry or whatever. This is not a new technology as we reported over a year ago, and if one of the big government bodies pops and orders thousands of rifles, everyone is just going to have to wait. Teludyne is a self-financed company, and though we wouldn’t be suprised if they get bought by one of the big players in the gun industry, today they are still flying solo and can’t accommodate much more business than they currently have. There is this new dealer program as well that is going to bring in a good deal of guns, so if you want your gun StraightJacketed, send it in today. |

https://www.teludynetech.com/

If you read our original article on the Teludyne StraightJacket, Ultimate Accuracy Makeover, you may have been one of the naysayers who didn’t believe you could take a $300 deer rifle (one of the two guns was a Savage Axis) and make it into a 1/4 MOA gun, but it was indeed true. For this year’s SHOT Show, Teludyne has contracted the H.P White testing certification organization to prove what we figured out long ago. The StraightJacket is the most significant development in long range rifle accuracy possibly ever. After going over the testing a bit we’ll explain again what the StraightJacket is, and more importantly, why it is.

This H.P. White testing will be a milestone in the history of the Teludyne StraightJacket as more and more people understand the Teludyne discovery and manufacturing process, and actually send Teludyne their guns for this inexpensive, $400-$600, complete accuracy makeover. I am sure it wasn’t cheap for Teludyne to pay H.P. White to confirm these results, so please pay attention, and download the PDF of the certified results if you still doubt it. Hold on to your hat. This is some pretty intense stuff.

First, Teludyne ordered an off the shelf Remington 700 in .300 Win. Mag. directly from Remington. It was sent to the Greenville County Sheriff’s department for testing, to ballistically “fingerprint” the rifle. The Sherriff’s department then sent it to H.P. White for accuracy testing. The conducted their test at ambient temp, as well as -65F and 160F. Then they sent the gun to Teludyne for a StraightJacket. It was then returned to the Sherriff’s department to match the “fingerprint,” which it did, then they sent it to H.P. White again, for the same battery of accuracy tests. The same thing was done with an stock M4, so they could present these results to the military.

Like any quasi-governmental testing (the government uses H.P. White instead of their own labs), trying to make sense of the results isn’t the easiest thing. But what we can make out from it is that H.P. White tried to duplicate all the things that would throw accuracy off shot to shot in the field. As you’ll see in the video that is posted with this article, the eloquent Noel Lasure is now famous for explaining that the StraightJacket system is “a cold bore shot every shot.” This was the focus of the testing.

H.P. White tested both the standard guns and the StraightJacketed guns with both cold bores for every shot, ten shots. The factory new Remington took 55 minutes to complete this test. The StraightJacketed Remington took 15 minutes. Accuracy was marginally better for the StraightJacket over those true cold bore ten rounds. As an aside, and I have no verification of this, I suspect that the “fixture” H.P. White used was the HySkore machine rest. In our experience this rest is not capable of less than 1 MOA, while an experienced professional shooter like our resident US Army Sniper Ben Becker is easily capable of 1/4 MOA. I would like Ben to shoot that StraightJacketed Remington and see what it really shoots.

Accuracy tests were also conducted at temperature extremes, minus 65 degrees, and plus 160 degrees Fahrenheit. As you can see in the charts, the StraightJacket drastically improved accuracy in these extremes. They also did a “sun test” and pointed a torpedo heater at one side of the barrel five feet away for an hour, then fired 10 rounds with no cool down. This is perhaps the most significant test, because uneven heating by the sun is very common in battle, where you sit for a long time waiting, then a lot of action happens at one time. The results of this test are dramatic. Click the graphics to make them bigger on the right here, or download the PDF to view them, as well as to read the official H.P. White reports, and a whole bunch of velocity data that we assume is there to show measured consistency in the ammo from one test to the next.

There are also a test chart of ten rounds after 20 rounds, where the original Remington showed 192 degrees and the StraightJacketed same gun came out at 155 degrees (more on this below in the explanation). You may be asking, “why on earth did they use ten shot groups for most of this stuff? ” but that is the whole point with the StraightJacket. Where normal rifles have to be accuracy tested with cold bores at three round groups, the true improvement of the StraightJacket shines over ten and more rounds, and the more rounds the better, and the faster the better for the StraightJacket. As more rounds are added to the test, faster and faster between shots, a normal rifle will open way up, where the StraightJacketed rifle will stay constant.

If you haven’t read the original article on the Straightjacket (and don’t feel like clicking out), the Straightjacket is a new technology that adds rigidity and heat dispersion to your existing rifle barrel. It is a steel (and now titanium) sleeve that is pressure fit onto your barrel. Telyudyne fills that sleeve with some kind of proprietary and top secret mixture, then they weld a cap on the top, or a cap with a muzzle brake. You send your rifle to them for this process, and for bolt rifles they will mold and fit your existing stock, polymer or wood, to the new barrel profile, which is about an inch and quarter wide. On AR-15s, a free float handguard is required. The Straightjacket costs from $400-$600 depending on your rifle and what material you want for the jacket.

If you are looking at the pictures and think this is just another heavy barrel gun, that isn’t what is involved with the Teludyne StraightJacket. A heavy barrel is steel all the way through, and it is machined from a solid chunk of steel. For generations, competition shooters and serious target shooters have been using “heavy barrel” versions of rifles, but while this offered a marginal improvement over thin barreled rifles, it was never the optimal improvement. The thinking of the heavy barrel methodology goes that because the barrel is thicker, it is more rigid, and therefore flops around less when a bullet is shot through it. The thickness also is thought to help as the barrel heats up, because a thick barrel can only flop so much, or so the thinking goes. This actually isn’t true in practice.

The problem with the heavy barrel methodology is physics. Even a two inch thick heavy barrel is all steel, and all one piece. It heats up uniformly, and tends to hold the heat, like a cast iron pan. As you shoot more and more rounds, the barrel gets hotter and hotter, and as a uniform mass of steel that is a slave to its own physical properties, it gets floppy, even though at cold temperatures it is technically more rigid. Being a solid mass is also a disadvantage because all of the molecules are lined up with each other and tend to “flow” the same way. So though a heavy barrel will be more accurate, cold, than a thin barrel gun, the accuracy improvement drops off as you shoot rounds without letting the barrel cool down. Heavy barrel methodology is a baseline improvement, not an optimal improvement. What you want is something that gives you as close to a “cold bore” shot every time, and now we understand how to do this with the physics of the Straightjacket.

The Straightjacket uses a two material approach. The steel or titanium jacket is like a Jello mold press-fit to your barrel for the poured in media. This second material media is poured in and bonds itself to the steel of the barrel, and this proprietary compound is most likely made of some kind of aluminum or copper solution with polymer or ceramic, or both. Whatever it is, it for sure has a better energy transfer coefficient than steel, because it acts as a heat sink, wicking heat away from the chamber and barrel. You can literally chew up rounds with mag dumps at full auto and the chamber will never get more than a couple hundred degrees, as verified by H.P. White, below.

Having that second material, encased in yet a third material (the jacket), makes it so all the molecules of the barrel are not in a straight line, or even physically connected, to the rigidity material. So you have a heat reduction, and by all accounts this is the most significant aspect of what hurts accuracy in a rifle, accompanied by added rigidity. The barrel of the rifle is now encased in the poured in mixture and trapped in the steel or titanium jacket. In our tests this turned guns that were already good guns, MOA or better, into 1/4 MOA guns. We used a Savage Axis (a $300 entry level deer rifle) and a Sako A7 (a $750 version of their expensive guns), and both guns shot into just over an inch at 500 yards with 5 round groups, and ten round groups were just over two inches.

The good thing is that now, nobody has to believe us. Don’t get me wrong, when we did that first article, hundreds of you guys sent your guns in and Teludyne was slammed for six months, but for all the naysayers out there, we wanted to do this follow-up with the ultimate gotcha. Though Teludyne vested a lot of faith in the testing ability of GunsAmerica, and they have become genuine friends, they eventually had to go and figure out how to pay what I’m sure was a ton of money to have this stuff certified by H.P. White. See the figures here for some of the actual test results, and download the PDF of the tests if you really want the whole story.

Heat Testing Full Auto – 13 Mag Dumps

We didn’t even mention the second test in the beginning of this article because the story is already pretty complicated and in many respects, the Teludyne StraightJacket is not very soundbyte-able. It is a complex products with a lot of genuine benefits that aren’t a lot of fluff for a serious shooter. One of these is that the heat sink of the jacket keeps the chamber relatively cool over mag dump after mag dump after mag dump of full auto fire. This leads to an ability to shoot an indefinite amount of rounds with no cook-offs, and it increases accuracy over sustained automatic fire. It also protects your gun from chamber erosion, and Telydyne has test guns that have fired upwards of 20,000 rounds that show no chamber erosion whatsoever and can’t be told from a brand new chamber.

H.P. White took a brand new M4, with a mil-spec barrel, that had been Straightjacketed by Teludyne, and fed mags into as fast as they could full auto until the gun failed, which was at 13 mags, or 390 rounds (there was a bur in the chamber that finally shut the gun down). They did this in 3 minutes, 40 seconds, then they measured the inside chamber temp and the inside barrel temp, and they left the probes in. The highest temp they could record anywhere was 207F. After the same test with a standard M4, no Straightjacket, that chamber would be over 1500 degrees and it would probably permanently damage the gun.

Teludyne routs the gas system through the StraightJacket media, inside the jacket, so the heat sink effect wicks the heat from the chamber, the barrel, and the gas system. So the gas that usually bakes onto the bolt carrier group in an AR is cooler, and doesn’t gum up the gun. The result is a gun that is much more reliable, and that can run indefinitely without cooking off rounds and without losing its accuracy, provided it doesn’t have a chamber burr like this test gun that unfortunately did. It would have been interesting had it not broken down and the results showed that they ran out of ammo, which is generally what has happened in past tests.

If you are an AR-15 owner, or 3-Gun shooter especially, you may want to send a gun into Teludyne as soon as you can. Teludyne has a 3 month wait list on AR-15 outfitting right now, and this article will generate a large influx of guns as the last one did. This stuff is real. Read the report. You don’t have to believe GunsAmerica anymore. We tried out the new titanium version at SHOT and it greatly improves the balance of the gun. The StraightJacket is not heavy like a heavy barrel. It does ad some weight, but only about a pound and half in steel. In titanium it is even less, and it balances much better.

If you are serious about rifle accuracy over sustained fire, the Teludyne StraightJacket is a product you have to try. As we explained in the first article, it is a stretch of faith, because you do send them your gun to permanently alter forever. It is a lot less a stretch now that you can read the H.P. White testing, if you are one of those who look before you leap and the more proof the better. We treasure our StraightJacket guns and they are the only guns in the safe with permanent zeroed optics on them, “just in case.” And we do plan to do another project with Teludyne, hopefully soon with the titanium and a .338 Lapua Magnum with that really cool APO Chassis System you may have read about a few days ago. Ben can shoot better than the fixtures at the H.P. White labs, we are quite sure of it, so stay tuned for real tests from GunsAmerica, the real authority in rifle accuracy!

And again, don’t say we didn’t warn you, and please don’t whine in the comments about wait times. It would be a good idea to call Teludyne as soon as you can after reading this if you think you want to send them a gun, because the wait-time will increase as a result of this article. Right now for bolt guns the wait is only 30 days, but the AR-15s can’t come back much quicker than 90 days. They also do shotguns for Turkey Shoot competitors, and they had an AK-47 version at SHOT as well. As we explained in the first article, there are Olympic shooters using StraighJackets on .22LR rifles, and they have shown much less variance in temperature extremes, as it showed in the extreme temp tests on the Remington in the H.P. White tests. You can get a Straightjacket for most guns, including all bolt rifles, left hand included, all AR platforms that have a free float handguard, your 10-22, and a lot of other small semi-autos, but not for the M-14/M1A/Garand.

Now all the “faith” that us early devotees showed isn’t required and the naysayers can just read the H.P. White report, the Teludyne Straightjacket has arrived, though we don’t feel that even the H.P. White report scratches the surface of what you can actually prove with this incredible and exciting new technology. We didn’t even bother to mention the effectiveness of the muzzle brake in this article for instance. To order your StraightJacket you have to ship your gun to Teludyne, so visit their website to learn how, and to contact them directly. You won’t regret the decision.

New for 2012, Teludyne now has a dealer program, so if your dealer has a shelf full of bolt guns that won’t sell, he or she can send them to Teludyne for StraightJackets and have guns in hand for customers who either don’t have or don’t want to send their existing guns to Teludyne. We have heard stories of old A-Bolts with wooden stocks turning into viable competition guns, and it is a great way for your local gun dealer to meet some of the demand for the Teludyne StraightJacket. Have them call for more information. We are only at the beginning of the success of this technology, and those who get there early and establish themselves with Teludyne will get preference later when everyone wants a StraightJacket gun and very few people have them. This is only the second chapter in the history of the Teludyne StraightJacket and it will be interesting to see how it all unfolds.

If I am understanding this correctly, it seems to me that a thinner contour barrel would actually be better for this application. The heat sink would pull the heat from a thinner barrel faster than a heavy barrel and cool it faster. If the OD of the sleeve is the same size, it would also allow for more heat sink material with a thinner barrel. Am I understanding this right ?

I found this product and was curious.

I have a few firearms, but I am not a hard-core gunner. However, I am a SERIOUS science nerd. So, the ‘proprietary mixture’ language caught my eye. It sounds like 50 mpg gas treatments.

So, I went and looked up Teludyne’s patent applications. In those, they do NOT patent a specific epoxy: They claim plain old cement, epoxy, or, most telling, epoxy with metal shavings added. Hmmm. Metal shavings.

Here’s a link to the patent application:

http://www.faqs.org/patents/app/20110113667

Metal filled epoxies are used for high thermal conductivities. For example, computer heat sink compound, or boron-nitride loaded epoxies used for industrial potting applications. These materials have thermal conductivity ratings well over ten times as high as air, and can potentially go MUCH higher than that.

Here’s a link to high thermal conductivity epoxies you can buy commercially:

http://www.omega.com/pptst/OB-100_OB-200_OT-200.html

The Omegatherm200 product there has a conductivity about 50 times as high as air, for example. Hmmm. Perhaps 50 times as much conductivity from the barrel, as a sample number. Hmm.

I then checked out Teludyne’s site, and found that the steel they are using for the tubes is 1008. This is a pretty bland steel grade, except that if you look it up, you find it has a thermal conductivity of around 59w/mK. This is about as high as any steel grade gets. Here’s a link to that info:

http://www.efunda.com/materials/alloys/alloy_home/steels_properties.cfm

Reading the patent, knowing the science and physics of the probable materials, and knowing for certain the effects of older sleeving methods, I think there’s a solid case for a real effect here. Firt, the extra mass around the barrel soaks up some heat due to the specific heat rating of the materials. Then, the larger surface area of the highly conductive fat sleeve gives more area to dump that heat to the external environment. If the barrel diameter goes up by triple, you have triple the surface area, it’s a linear relationship. I’d wager that most conversions would see at least a tripling of the cooling rate, and possibly quite a lot more.

This is not crack-pottery. This is a sophisticated heatsink for your rifle barrel combined with an efficient radiator system, all rolled up in a composite sleeving system which adds rigidity. There are a LOT of things going on here. The varying densities of the barrel/epoxy/sleeve system is probably damping shocks much better than a monolithic barrel could. The high thermal conductivity of the sleeve steel and the epoxy ‘smooths out’ gradients and radiates the heat away much more efficiently than a heavy barrel would.

I think I am convinced. 🙂

not to mention it actually works lol. We just sent them two AR uppers so stay tuned.

I will be paying attention. I have a brand new FNAR that may be a candidate for this treatment. 🙂

Also, out of curiosity, is there any info about performance differences between the aluminum, steel, and titanium versions?

I ask because the thermal conductivity of titanium is VERY low for a metal: This is why titanium watch bands feel warm to the touch compared to other metals. Titanium, for example, has conductivity less than a fifth of the 1008 grade steel they use.

Conversely, aluminum has a very high thermal conductivity, about double that of the steel tube.

I’d be curious if there are any performance differences. If there are not, that means the epoxy filler is probably the limiting element of the system, and might point them in directions to improve their product.

I’d also be very curious if they use any kind of a high-emissivity coating. Or have plans to texturize the surface of the tube to increase radiative area.

The titanium is pretty new I think they have only done a few. When it comes out I’m sure Al will comment about the comparison with steel. Unless you have sustained heat over a long period of time I don’t think it’d make that much of a difference. I think that would be the on circumstance where a radiator effect would help additionally as well, but creating more surface area. With today’s ammo prices not a lot of people who don’t shoot tax dollars are going to shoot that rate of fire.

There is nothing greater than new technology. I personal enjoy such technology at the age of 57 that just wasn’t there when I was twenty. Many of the new technologies envolving weapons started thru and from the military as well as the individuals who tinkered and came up with many weapon improvements we injoy; like John Brownings 1911. We all now enjoy a great deal of the actual military technology today. I am all for this kind of technology that can make the kind of difference this one has shown and claims. But, with all that said its apparent if you plan on driving in the Daytona 500 or the big Indy race you will want to squeeze out all the horse power you can from your race car. Its not going to be feasible for all of us as gun shooters. So, to enter such races its a shame that this kind of technology has the same cost as a new gun for us good old boys. Kinda like needing the backing and the money to have the previlage and chance to run in these kind of races. I would if I could, just like anyone else. Maybe before my times up the cost of this technology will be affordable to someone such as myself. Hopefully before gas price makes up the difference. This kind of technology will truly make the difference for those that shoot rapid sessions. A real plus for long range shot consistency.

A couple things to keep in mind –

Friction and wear can be reduced through heat reduction in most any mechanical system that features significant bearing surface area. They cannot be eliminated. Clearly, using a heat sink will increase the rate of heat transfer and facilitate more efficient cooling. The question from a wear perspective is the operating temperature, in the case of a rifle – the temperature of the INTERIOR of chamber/throat/rifling while the bullet is actually travelling/stressing that part of the system. Some documentation in this area, both theoretical and experimental, to demonstrate wear rates would go a long way towards making headway into the camp which wants justification of the longevity claims. As far as accuracy – the article has it right: if the consistency of a cold barrel shot is what you want, anything that cools the barrel more quickly will facilitate taking a cold barrel shot more often…or, in the case of rapid fire, minimize degradation due heat build up.

All that said, consistency is the key to what we call accuracy – a repeatable result. In shooting, this is closely related to the pressure curve. Pressure affects the way in which the bullet enters and engages the barrel throat. Pressure is ultimately what folks are seeking to control with closely regulated OAL, charge weight, case thickness, crimping, seating depth, etc. It’s the reason slow and fast powders can yield similar velocity and vastly different accuracy and why a single powder has an accuracy sweet spot (or spots). I would be interested to see a rifle developed with an Optimal Charge Weight load (or some other means of optimized barrle harmonics) shot at different temperature profiles (with the Straightjacket being used for subsequent testing after a performance base is established) and measured for both group size and point of impact deviation. To that same end, I would be interested to see a rifle set up with a strain guage at several points on the barrel and chamber, tested in different temperature ranges, outfitted with a Straightjacket and then retested. The comparative results from the strain guages should be instructive. Obviously, enhancing the barrels ability to resist deformation and provide a more uniform engagement of the projectile from shot to shot is a plus…any way it is achieved.

It might be interesting to see a collaboration with carbon fiber barrel wraps as well. The next step is factory produced barrels integrating this technology. If two barrels are executed with equal precision, the barrel with better mechanical properties (i.e. stiffness, surface hardness, heat transfer) would be the one to have. It might be time to shop around and see if someone like Shaw Barrels will get on board and do some collaboration.

v/r,

Dave

After spending 5 years testing the StraightJacket (and two years on the market) on any rifle in sight, we concluded that there is nothing more important than a rigid barrel. Second would be a crown truly perpendicular to the bore and third is consistent velocity. The managing of the heat is what keeps the core group from moving around the target and wearing the barrel out.

One must remember at this point, we hired the Laboratory that simple folks like the US Navy SWC and USSCOM use to prove out products, so at this point…you must make a decision, are you going to believe things might be changing (gee, that never happens) or are you going to stick to, well…the past?

Sorry if you just don’t get it.

Unfortunately that is where we are at Al. There was a flat earth society for how long? People still believe in Darwinism, even though no real scientist has believed it for over 20 years. Comments on these things generally fall two ways. They are either positive people who are just grateful to read good stuff and learn stuff they didn’t know yesterday, and there are the negative people that show up over and over and over. A lot of them we just delete, but on stuff like this we let them through just so people can see what you guys are dealing with, and how just plain old dumb people can actually be. As for the “official” testing, we are living in an era of disinformation from the government, and all of these “official” government type testers are completely irrelevant for those of us who trust none of them. That they couldn’t get an inch out of a 700 with a StraightJacket as you know is a joke, but some of the stuff is thoughtful and interesting, and we definitely can learn some aspects of the StraightJacket that would be difficult to test at home. I tell people to google around and search youtube and try to find even one person who has gotten a StraightJacket and is dissapointed. Even the guy who admittedly can’t shoot MOA, and I am generally one of them for some reason, admit that it is still an improvement over what they could do before, and that it stays consistent as the gun heats up. I think the customer testimonials make the whole issue game over, but then again, the world could actually be flat. -ph@ga

I always enjoy reading about the StraightJacket system, and have thought of it many times when doing physics and metallurgy. One thing that I am very surprised that I haven’t seen anyone mention is in the test with the AR where temperatures are reaching 1500 F. This is over the austenisation line (1350F) for all kinds of steel, and depending on the carbon content and the amount of time that it stays at that temperature, the barrel steel may become pure austenite. An iron/carbon mixture without any heat treating is said to be in a ferritic state and has a ‘large grain’ lattice structure, when it’s heated above it’s austenisation temperature it becomes non-magnetic and is in a plastic state (in that it can be deformed and hold it’s new shape). When it is quenched it becomes martensite. The quenching deforms the lattice structure. the more rapid the cool, the more deformation, the harder the material, the smaller the grain size, and the more internal stress. When martensite is heated above that austenisation temperature and allowed to cool slowly (over several hours) it is annealed, which softens the metal by allowing the deformed lattice structures to become more regular, and in turn more susceptible to damage. Barrels do have other treatments to help overcome this phenomenon, however, with the straight jacket barrel system no temperature along the length of the barrel ever becomes even close to any kind of a temperature that would allow any change in the lattice structure of the barrel. Obviously, there is a great deal more going on than just heat, but this is one area that can be quantitatively proven and show mathematically how if a straight jacket is installed on a brand new rifle barrel the POI should never change after any number of rounds due to heat effects.

I first heard about the StraightJacket system a few years ago through a mutual friend in the gun industry. Then, finally, at the 2010 Big3 event in Kansas I got a chance to put my hands on one, and was truly impressed. These guys were able to do something that no one else could or was willing to do. That was to admit that traditional barrel development had reached a plateau, and not only were they willing to admit that but they visualized a way to overcome that plateau.

I’ve seen first hand what this system can do for a rifle, and believe me when I say that I had my fair share of hesitations about the claims. I am really looking forward to getting my hands on a rifle with one of the new titanium systems on it. I’ve heard that they are going to be at Big 3 east this year as well, so hopefully they’ll bring a rifle or two with it installed for some range testing.

I have the straight jacket on several rifles. On a top notch barrel you are not going to see anything on the first shot or the 2nd or the 3rd. On the 4th consecutive shot you’ll start to see the improvement and it get more and more dramatic after that. For me it took away the gun as the biggest source of inaccuracy. Regretfully I found I needed a lot of improvement and what I blamed the gun for was actually me. I trusted the gun and have gotten steadily better at shooting. While no great shakes I can hold 1/4 Moa at 100 yards now through a whole box of off the shelf Hornady ammo.

It’s just as I was told once. The worst enemy of revolutionary technology is a guy who thinks he knows because he has to change his paradigm in order to grasp or believe what they are being told. Its like trying to explain television to a painter before the invention of photography.

I have no problem believing the science. If you keep metal cool it wont get soft or expand. Rigid/cool metal does not wear out like soft/hot metal does. A system that depends on a rigid tube of metal ,that is not expanding, would benefit from any cooling. This would reduce “barrel flop” and keep the diameter of the barrel consistent. Consistent diameter equals consistent bullet expansion and better retaining of propellant gasses that equal consistent velocities.

I see the benefit for high round count military guns, competition shooters or velocity/accuracy geeks.

For the person who takes their rifle out twice a year to shoot some deer, turkey or hog, forget it. Buy a nice rifle with a nice scope and dont trouble yourself with putting every round within the diameter of a dime. Your not going to get more than two, or extreme case three, shots off at an animal either way. Choose your shot wisely, hit it solid in the vitals, and enjoy the meat on your table.

Read the words carefully people

They said “Telydyne has test guns that have fired upwards of 20,000 rounds that show no chamber erosion whatsoever and can’t be told from a brand new chamber.”

They did NOT say “Telydyne has test guns that have fired upwards of 20,000 rounds that show no THROAT erosion whatsoever and can’t be told from a brand new THROAT.”

There is NO POSSIBILITY WHATSOEVER of any centrefire rifle shooting 20,000 rounds and showing NO throat erosion, not even a .22 Hornet.

I use to compete in service rifle competition. What we found was if a service rifle was used only for slow fire (about 1 shot per minute) the barrel would last from about 13,000 to 15,000 rounds. If the rifle was used across the course 40 rounds slow fire (200 & 600yards) and rapid fire 40 rounds (200 & 300yards)( two shots/ magazine change/ 8 shots in one minute) the barrel would last about 7,000 rounds. If the barrel was used for all rapid fire (200 & 300 yards) the barrel would only last about 4,000 rounds. I’ve heard that if you shoot 100% at the National Infantry Trophy Team rate (rattle battle) the barrel is gone in a little over 2,000 rounds.

I cannot believe a barrel can last 20,000 rounds with no evidence of throat wear. I have an M-6 scout and was surprised the first time I shot the lower 410 bore barrel. Within a half second of pulling the trigger i felt the heat in the barrel.

i am following this discussion and have a few questions. in my mind rifle accuracy has 3 basic components: “wood” to metal stock fit; the action to barrel fir,addressed by “blueprinting”; barrel issues like consistet bore diameter,stiffness and all the other barrel only issues. my questions are: if one does this i guess blueprinting must come first? followed by correction of any stock fit issues? then sleeving operation above? i am not so sure that any single area can give predictable inmprovement in isolation. economics does become an issue for me and i see the cost of all 3 things being in excess of $800 over the cost of 2 not cheap rifles i own and have in mind. then there are operator issues. i am an MOA shooter. NOT a sub MOA shooter. improvement into 0.5 area becomes an unknown as well.

Mike,

We take, on a regular basis, off the shelf plastic molded stock hunting rifles and turn them into .5 to 1 MOA rifles, with NO other modifications than the StraightJacket Barrel System. (remember this is not with 3 cold bore shots, it is sit down and shoot as many as you want)

Yes, this sounds like we are leaving out reality and the things that time and trial has proved to us we MUST do, its great isn’t it?! It hurts one’s brain to think that all these things have been band-aids all this time! We’ve been forgetting the barrel, which almost everyone has excepted as being “as good as it gets”.

WE’RE ROLLING DOWN A NEW ROAD NOW! This is a new starting place for accuracy, SOME of the things we’ve done in the past, all things that took me decades to learn, may come along with us. Although, when you can get .5 MOA out of a Factory Walmart grade hunting rifle at 500 yards, with monotonous regularity gun after gun after gun, its time to lighten the load and look ahead.

I make custom one of a kind Flintlocks and believe me, the things I learned for doing that are burned into my brain as must do things and for that vintage firearm, it remains the truth, as is the case with traditional modern rifles. I don’t want anyone telling ME that MY training is obsolete! but they stopped making buggy whips for a reason.

For the person that is a modern everyday user of high powered rifles this system will ruin you, I can say that every rifle I have that is appropriate, now has a StraightJacket. Without it, I was just wasting my ammo and time fighting the mystery part of shooting that we all know exists.

I hesitated to bring this to you all for this very reason, the disbelief. I’ve been making guns for 30+ years now and I wasn’t sure I believed it for the first two years! (that would be the hesitation) and I invented it.

Then I thought, Yes! I want every American to be able to see that we are still the leaders in Riflery world wide! This product can make that happen as a giant leap in ability for every rifleman because the rifle barrel is now complete.

You can blow it off, but I’m really excited even after all this time and trouble fighting through the skeptics and the day you get to try one you’ll see that there is no going back, it is the next leap forward, because the StraightJacket simply works!

I have worked on this problem in a different way for 20 years. My quest was to shoot through the transonic without a change in accuracy. It can be easily proven that almost all bullets are out of balance to a degree that varies with construction and the manufacturer. While experimenting with different twist barrels I found there is a rotational harmonics in all bullets. When the bullet is turned at the correct RPM the rotational harmonics corrects the imballance in the bullet and the bullet rotates on its true longitudinal axis. When this is achieved while the bullet is in the barrel there a dramatic increase in accuracy because the bullet is not wiggling the barrel (called barrel harmonics). That is why the group size is smaller with a bull barrel. The combination of the sleeve and whatever the filler consists of add mass to the barrel which reduces group size. As a steel barrel heats the harmonics or how it wiggles change due to stresses in the metal. Dampening the wiggle will improve group size; turning the bullet at the correct rpm eliminates the wiggle.

this would be great on my m-60 when i was a gunner ,,not having to swap out hot barrel’s

have one and it works just as advertised. After your first post in 2010, I was very skeptical, as anyone SHOULD be when a new product comes along with such claims as Teludyne makes. However, I took it a step farther and actually put my skeptical money where my skeptical mouth was and ordered a Straightjacket 20″ AR upper in .223, in Feb. 2011. Well, I’ve digested the Kool-Aid, my skepticism is gone, and I’m about to buy another.

My Straightjacket is consistently cutting 1/2″ groups at 100 yds., and sub 2″ groups at 300 yards when I do my part with the right ammo. Those are 10 shot groups through a warmed up barrel. It’s a 1:7 twist, and really likes the 68, 69, and 77 grain Sierra’s. It does seem somewhat ammo sensitive as I’ve tried other loads and things opened up to 1″ to 1-1/2″ groups through a warm barrel. I say “warm” because I still have not been able get it too hot to touch, even after a 60 rnd. rapid fire effort to heat things up.

I’ll disclose here that I purchased a new Teludyne built AR upper, not one that I had previously owned and documented it’s prior capabilities. That is my next step, to take 1 of my other rifles (a pencil barreled bolt gun), shoot 25 rounds in 5-shot groups onto 5 separate targets in one sitting, then repeat that after sending it in for a Straightjacket treatment, and compare the results.

The StraightJacket process is not just for rifles. It also works on shotguns. Both my wife Doris and I are shotgun still target shooters. We had StraightJackets put on our shotgun barrels prior to the 2011 season. I can only testify to the results, not the reasons for them but frankly, that’s enough for me.

We measure performance by how many #6 shotgun pellets we can get into a 3″ circle at 40 yards. Fortunately, or unfortunately at times, all of our shots in the sanctioned events in competition are witnessed and recorded. Using a Savage bolt action shotgun, my best sanctioned scores had been in the high 20’s but after the StraightJacket, I shot a sanctioned score of 45 in Medina, OH last spring. At my home range, in non-sanctioned shooting, I’ve seen scores as high as 54.

My wife Doris, using a StraightJacketed Remington 870 Express shotgun, won the Women’s World Championship in that same sport last October.

We shoot offhand, using no rest of any kind and our events can be from 4 hours to up to 10 hours per day. While added weight does help with taming recoil from full power 3″ turkey loads, too much weight can really add to the fatigue factor over long periods of time. The StraightJacket system does add weight to the barrels but nothing like the all steel bull barrels that we see on some of the competition guns.

Lastly, we both have seen much more consistent patterns with the StraightJacket system in place. Holding a shotgun rock steady without a rest, especially after several hours of competition can be tough, it helps when your gun throws a dense even pattern that allows for some margin for error on the part of the shooter. Ours do that much better since the installation.

I sent TT a .308 Rem. 722 / Shilen – .5 MOA rifle last year.I cannot see much improvement accuracywise [probably due to my 73 year old eyes] – but I am TOTALLY convinced that the heat dissipation factor is valuable; Mounted in an AICS stock and wearing a Leupold 8.5 to 25 x 50mm ‘scope, it is a rig to compete ANYWHERE – and the muzzle brake is excellent.

Price and turaround time??

As the day today progresses, the turnaround time will go up. Thousands have read this article by 10am already and only a fool wouldn’t send Teludyne a gun. The price, as explained in the article, is $400-$600 for the StraightJacket makeover.

We have been working with this system for 7 years and we’re finding out things that will twist your brain…until you think about it.

The extra rigidity of the StraightJacket system has a much wider influence on the physics of the shot than we initially thought. We’re finding that the extreme pressure is damaging the steel in the barrel’s built in rigidity after many rounds no matter what barrel you use or how cool you keep the barrel. The steel is in a state known as “super cool”, which sounds like this would mean “cool,” but what this really means is that your steel barrel is still in a LIQUID form, as solids go. So the StraightJacket is actually holding up the whole works, shot to shot, and that is most likely the reason for the dramatic difference in accuracy after several rounds fired with no cool down.

When you think about it, all this time the real “magic” has been getting any accuracy at all from our barrels. The pressure is making them into a flowing, yet somewhat solid, liquid. Good job everyone that makes barrels!

There are two other issues that seem to keep coming up…heat and throat erosion.

What is really happening is the pressure, over 50,000 PSI, is damaging the barrel’s ability to maintain it’s composure (you try containing that much pressure 2000 times in a row and see how your spine feels) this “break down” of the steel cannot be seen with any normally available tools. Because of this we must go after what we CAN see, rifling wear. We have found that all the manufacturers have put in great work with their rifling efforts but for all this time we have hitched our wagon to a form of liquid that needs some help, and by wicking that heat away from the rifling shot to shot, it acts as a reset on the rifling wear to a large degree, and as it is explained in the article, we do have guns that have fired tens of thousands of rounds that you would never know aren’t new guns. Come visit and we’ll show you!

If your rifling is still good enough to consistently spin the projectile and evenly maintain the pressure from shot to shot, we can make the rifle shoot real good. Our customers have been universally very pleased, no matter what state their gun was in prior to the StraightJacket, and if you look around with Google and Youtube you will find nothing but positive on the StraightJacket experience.

Call us and we’ll talk…

Alan,

Teludyne Tech

864-334-5300

Steel has molecules? Oh really!

Metals, including steel, are made up of grains of positive ions in a crystal matrix, with a cloud of electrons. Alloying and heat treating distort the matrices, changing the strength of the metals. The loose electrons are what makes metals electrically conductive.

This is Metallurgy 101. Basic stuff. No molecules in steel, unless you count carbide inclusions. These are typically considered unwanted impurities.

Norm

Re: Norm Glitz,

I do believe the “Administrator” is correct.

“Molecules” per Dictionary.com:

“any very small “Particle”[Particle – a minute portion, piece, fragment, or amount; a tiny or very small bit: a particle of dust; not a particle of supporting evidence. ] I thought I would add – just in case.

Great article. I have little experience with guns and learned a lot from reading it. For me, like in science, the more real tested evidence the better. Ahh, this is science, isn’t it?

Well everything is science actually. In fact if you talk to the most advance theoretical physicists, there is nothing even actually here, similar to the oldest scientific theory, G-d is ONE. This would be the study of the science that is all around us that we live every day, but in very laymans terms, as has already been pointed out by molecule man here in the comments.

Never heard of Teludyne until it popped up on my computer this morning. I’m a 68 yr old individual that has been involved with electronics, mechanics, metallurgy, machinist work, gunsmithing, and experimentation in various fields for the major part of my life. That being said, I would be willing to bet that Teludine’s process/procedure works. 40 years ago I personally experimented with dissimilar metal jackets/casings on rifle and pistol barrels and had various degrees of success. The best of the bunch was a full length 2 inch diameter aircraft aluminum sleeve with a zillion holes drilled through it [looked like a big suppressor] driven/swaged over a major old school barrel manufacturer’s custom barrel. [pre 64 264 win mag] Before the mod it would walk high left 2 inches or more at 100 yds as it heated up. After the mod it would barely move a half inch at 500. [Believe it or not] Before mod after rapid multiple firing it would sizzle if you spit on he barrel. After mod you could wrap your hand around it and not get burned. I’m on a fixed income and I won’t be able to try Teludine’s system, but I can guarantee it to work in principle. Thanks for your time. Dave Henderson

I “build” precision rifles, starting with Savage 10/110 or Stevens 200 platforms. I have been using match grade heavy barrels for this, for years. My question is about headspacing and barrel work. I remove and replace barrels, lap the threads, lap the recoil lug, lap the receiver face, and set headspce tighter than factory settings. A lot of the lapping is done with the two pieces that fit together, lapped against each other to get as tight a fit as possible. If I send in a rifle for this proceedure, can I reset headspace, and do all this barrel work after it returns, or does the sleeve fit up to the face of the receiver? Is it possible to do the barrel seperately so my work can be done later?

I also went to the Teludyne Tech StraightJacket website and emailed them the above question. If they reply, I will post the answwer here.

Call and talk to Noel, who you see in the video. All of the guys in the video are the actual guys in the company, and now everyone has a face to match with a name.

Teludyne does not need to remove the barrel from the action to complete the process, so we don’t.

its great to see something that works for a change. i can’t wait to share this with my long range friend i’ll bet that between us we have at least several rifles that could use a little help

Keeping the barrel cooler which this product does might decrease throat erosion

Greg

I am a retired law enforcement, tactical shooter trained by both FBI and Army instructors. More importantly, my father worked for the government in experimental ballistic programs with large guns (aboard ships). From years of listening to his talks about ballistics and barrels , L over D , and coefficients,I picked a few things up. This technology appears to be sound and there is no reason it would not improve accuracy as well as barrel life due to lowering the heat by dissipation. I would be more interested in starting a gun from the ground up, based on this technology rather than retrofitting a heavy gun to try to squeeze a bit of accuracy out of a flawed starting point.

I though this was a bad idea till I looked at the REAL cost of custom barrels, basically they cost twice as much when your done and you don’t get a muzzle brake….you’re also stuck with the same old problems even if they are not as bad.

A quick factual update on the cost of barrel replacement vs. StraitJacket.

I looked up a certain barrel maker and jotted down their costs, I’ll keep it short and just give the total for barrel replacement with basic steps and nothing fancy. The same end options that come included with a Teludyne Jacket from this sample premium barrel company total $890 and it is a medium contour barrel that will also suffer from at least some of the same problems the old barrel was plaged with. It looks like to me that that is more than twice the cost just at face value, let alone the benefits you’d get from this new thing.

I read your original article on this, but I am not an early adopter, and I have not since then seen these jackets being discussed on the benchrest and high power forums, where typically there are a lot of folks aggressively trying new things. So where are the results of people winning competitions with this thing?

I’m not sure why this is superior to just putting on a new barrel? And what proof is there that it delays throat erosion, or otherwise prolongs barrel life?

You are probably just going to have to wait until it is in the mainstream, because some people just need that kind of proof. If you speak to the Teludyne guys, Alan especially, you will find that the company is made up of long range lifetime shooters, not salespeople. I’m not particularly impressed with the H.P. White testing, though they did dramatically demonstrate a few things, but I don’t know how you could watch the stuff at the end of the video where it is explained that the military testers have sent their own guns in, and not be deeply effected by this. If anything, at this point, distrust shows more about the person than it does about Teludyne. We proved the technology works over a year ago, and for a dedicated shooter, sending one gun in that has been a poor performer just to try it out is a no brainer. Search around on Youtube. There are tons of videos like this one:

http://www.youtube.com/watch?v=FfFbqfzaJ4I

Just how many people do you think are lying to you besides us?

“You are probably just going to have to wait until it is in the mainstream, because some people just need that kind of proof.”

That’s right, and I am one of those people.

“If anything, at this point, distrust shows more about the person than it does about Teludyne.”

“Trust, but verify.” -Ronald Reagan. Worked for him, works for me.

“sending one gun in that has been a poor performer just to try it out is a no brainer.”

So is spending the same amount to have a good gunsmith install a quality barrel from a top barrel smith, and hand loading.

Sorry, but I don’t believe that 100% of bad barrels are cured by this. Rigidity and heat dissipation might be important, but what if the barrel sucks because it has rifling and finish problems, or chamber/headspace problems, i.e. things this jacket won’t fix. Then you just flushed $400-600 down the toilet. And can you set a barrel back and rechamber once you put this thing on? I’m guessing no.

I wouldn’t be surprised if you could, but regardless, you would be guessing no matter what work you had done to it. So the options are leave a gun in the safe that you don’t ever shoot, or send it out to get a potential second life that will outperform some of your better and best rifles. The actual physics of the StraightJacket are being paraphrased even by the guys in the company. What tolerances it will correct for, and even the reasons you thought your gun wasn’t shooting well because of, have been turned on their ear. We are going to take our two rifles out to Manatee for Ben to shoot at 1000 yards next time we go up. He did the stuff in the first article with factory deer hunting stocks and factory ammo. To think how many of us have been playing with COAL and those Redding micrometer dies. We could all have completely missed what effects consistent rifle accuracy. Have you no wonder at what a huge rethink this thing is? $400 is a car payment, and a low one, for something that never does anything besides get you from A to B, and that doesn’t include insurance.

$400 is also a top of the line Shilen, Bartlein, Pac-nor, Krieger, etc. barrel, from companies that have decades of proving their barrels can shoot sub-moa, and won world championships. So unless this jacket will double or triple the competitive life of my barrel, then economically it makes no sense. Even if you have an old rifle, you can sell off the old barrel to reduce the cost of re barreling.

The fact is that throat erosion is what kills a match rifle, which has nothing to do with flex or rigidity in the barrel. Competitors with bore scopes have proven this over the years. That said, I am open to the theory that heat dissipation *might* help reduce throat erosion, but until I see credible competition shooters talk about how they got double or triple the barrel life with this jacket, I’ll stay “circumcised” 😉

The only way you can prove it is by doing it, and they have done it with ARs. I’m not sure what is confusing. Maybe you should volunteer to document the throat erosion, but, hmm, oh yea, you won’t believe yourself.

Jewish Marksman makes an intelligent argument — but only half way. He is right that it probably wouldn’t make sense to put a StraightJacket on a flawed barrel; analogous to putting lipstick on a pig.

A shooter should probably evaluate rifle improvements the same way racers evaluate modifications to their car for horsepower. Start with the modifications that will get you the most improvement for the dollar, but don’t bother putting a forced induction system on an engine with compression problems. Correct the rifle’s flaws and reduce the group size until you can’t go any farther without the StraightJacket…..